Online control method for particle size distribution in solventing-out crystallization process

A particle size distribution, dissolution and crystallization technology, applied in particle size analysis, material crystallization, material analysis, etc., can solve the problems of poor control effect and low product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

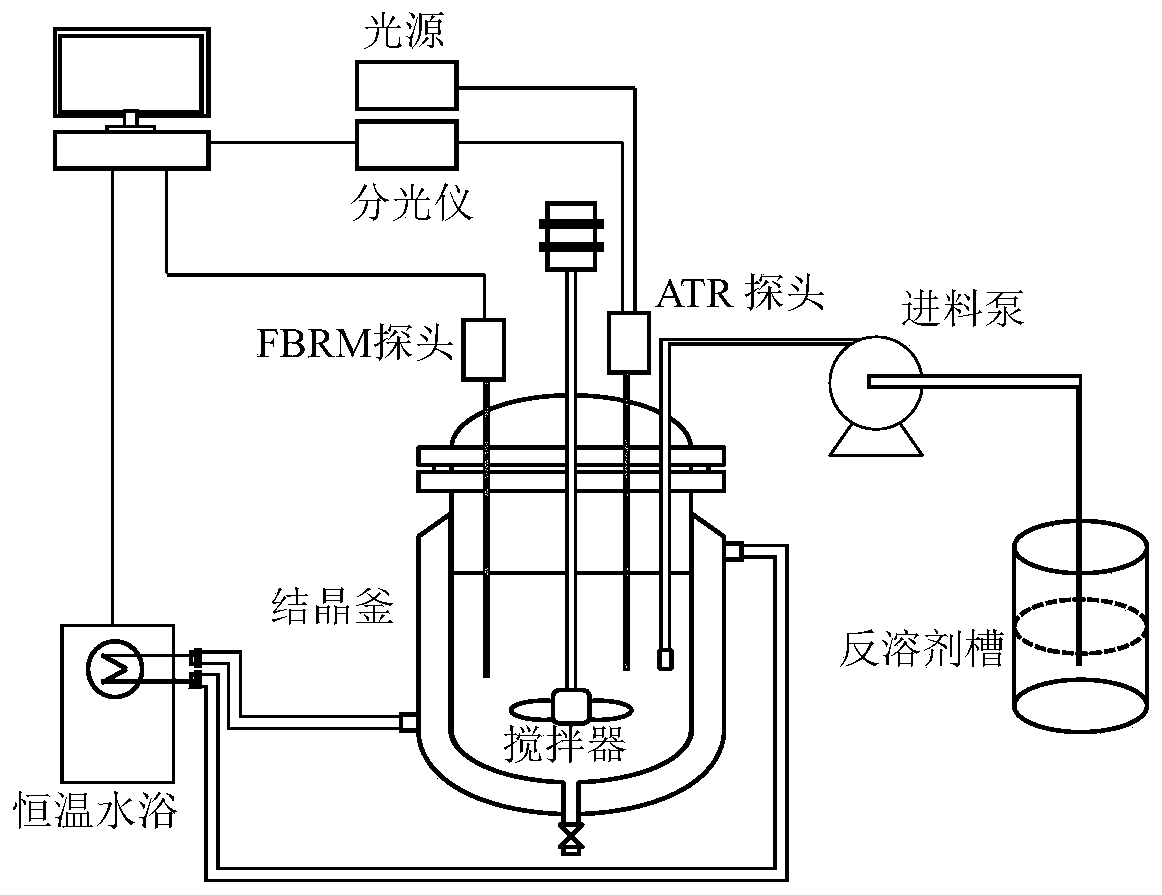

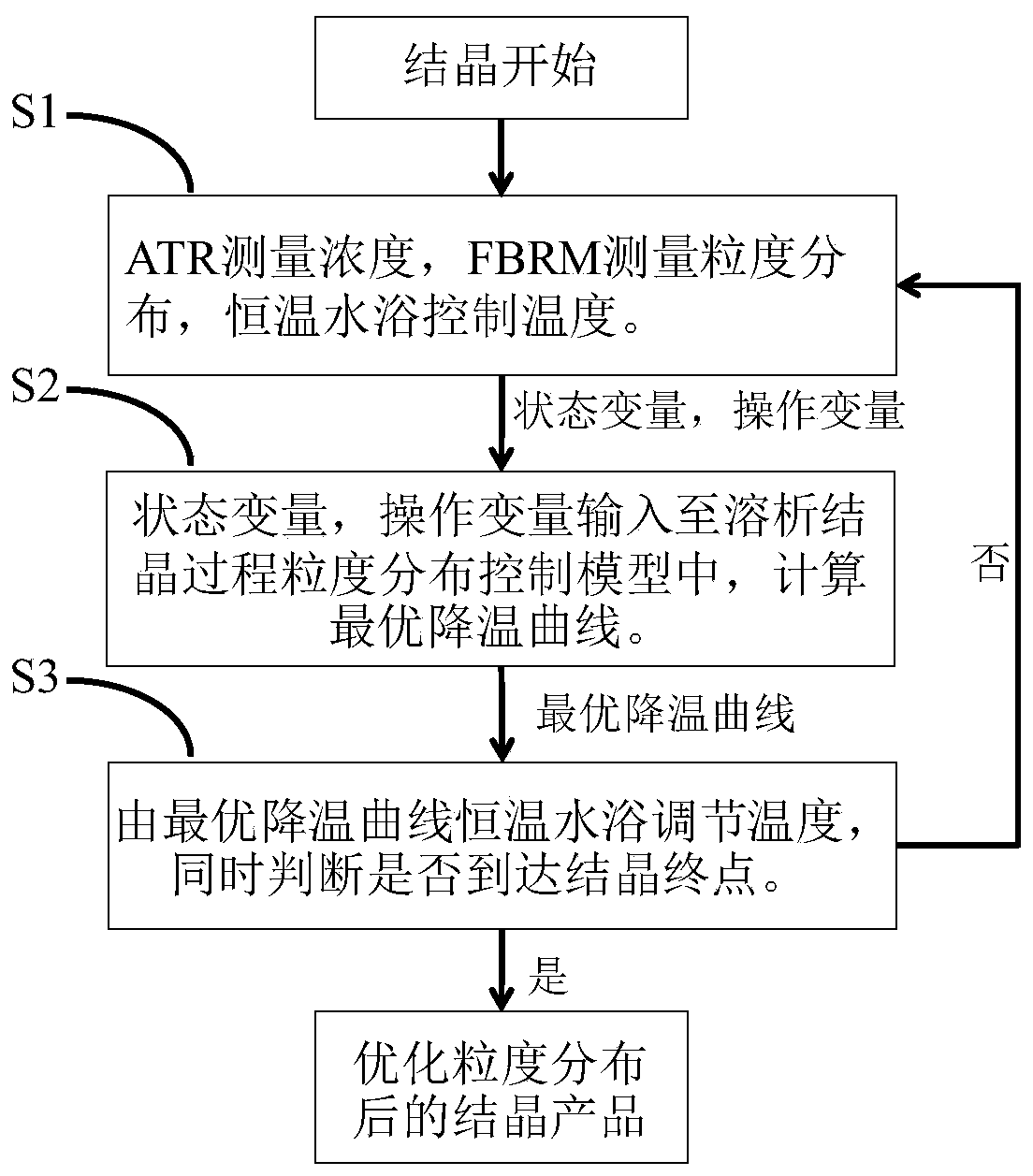

[0060] In this embodiment, the selected crystalline substance is artemether, as in figure 1 The on-line detection and control device for anti-solvent crystallization shown here applies the method for on-line control of particle size distribution in the dissolution crystallization process of the present invention to control the particle size distribution in the crystallization process of artemether.

[0061] Such as figure 1 As shown, the anti-solvent crystallization online detection and control device includes a crystallization tank, agitator, ATR probe, FBRM probe, spectrometer, light source, computer, constant temperature water bath device, anti-solvent tank, and feed pump; a constant temperature water bath is set around the crystallization tank device, a stirrer is provided in the crystallization kettle, and an ATR probe and a FBRM probe are also arranged in the crystallization kettle; the ATR probe is connected with a computer through a spectrometer; the ATR probe is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com