Method for manufacturing self-aligning graphene transistors by ion implantation oxidation

A technology of ion implantation and manufacturing method, applied in the field of microelectronics, can solve the problems of reducing interface scattering, the influence of medium growth speed is great, transistor performance degradation, etc., to reduce parasitic resistance and avoid difficult control of medium growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A kind of ion implantation oxidation realizes the manufacturing method of self-aligned graphene transistor, comprises the following steps:

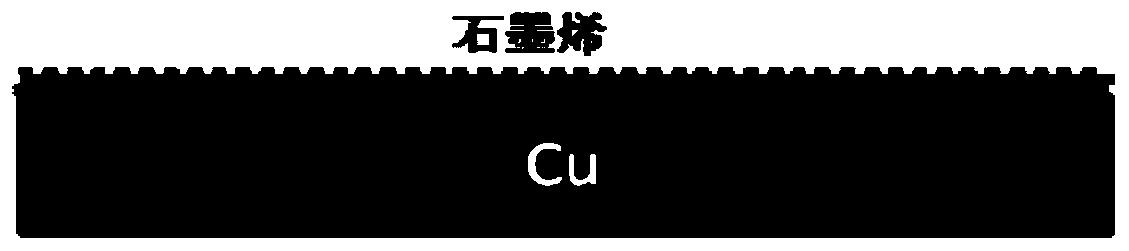

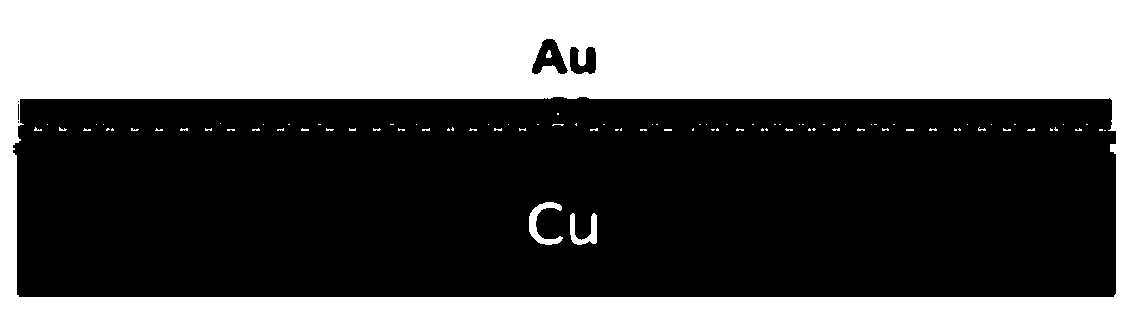

[0034] 1) Take the graphene prepared by CVD on the Cu substrate as a sample, and prepare 10nmAl / 30nm Au on the graphene joint Cu substrate, such as figure 1 , figure 2 shown.

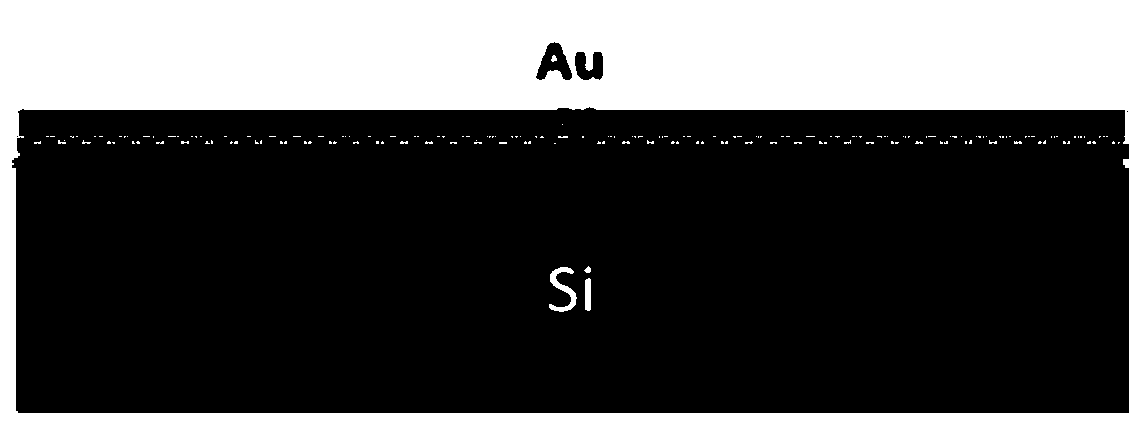

[0035] 2) Place the sample in 0.5mol / L FeCl on Al / Au and Cu 3 In the aqueous solution, the sample can float under the tension of water, and stand for 8 hours until the substrate Cu is completely corroded and dissolved, and the graphene is attached to the upper composite metal film to float, and the sample is then transferred to deionized water and left for 30 minutes to wash off the residual FeCl 3 solution, and then use a high-resistance Si sheet to pick up the sample from deionized water, bake at 90°C for 3 hours, and remove the residual water between the substrate and graphene, so that the graphene / composite metal is tightly attached to the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com