Germicide used for cleaning reverse osmosis membrane

A technology of reverse osmosis membrane and bactericide, which is applied in the direction of bactericide, biocide, biocide, etc., and can solve the problems of microbial resistance to drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

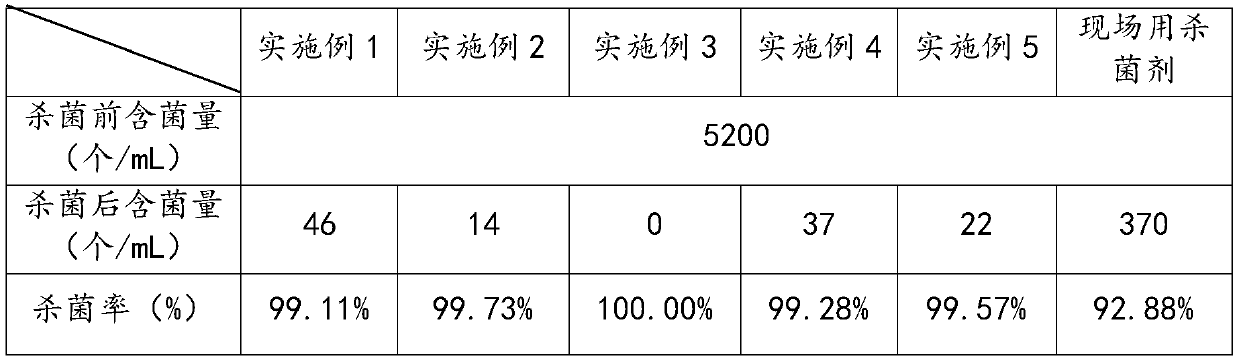

Examples

Embodiment 1

[0017] 1. Rinse the mixing tank clean, close the discharge valve, add 20% of the isopropanol, 30% of hydroxyethylhexahydro-s-triazine, 5% of isothiazolinone, 4% of glutaraldehyde and the 41% of the above deionized water;

[0018] 2. The stirring speed is 50r / min;

[0019] 3. After all the raw materials are added, stir for 20 minutes to obtain the bactericide for cleaning the reverse osmosis membrane. Example 2

Embodiment 2

[0020] 1. Rinse the mixing tank clean, close the discharge valve, add 30% of the isopropanol, 45% of hydroxyethylhexahydro-s-triazine, 10% of isothiazolinone, 10% of glutaraldehyde and the Said deionized water 5%;

[0021] 2. The stirring speed is 80r / min;

[0022] 3. After all the raw materials are added, stir for 30 minutes to obtain the bactericide for cleaning the reverse osmosis membrane. Example 3

Embodiment 3

[0023] 1. Rinse the mixing tank clean, close the discharge valve, add 26% of the isopropanol, 38% of hydroxyethylhexahydro-s-triazine, 6% of isothiazolinone, 10% of glutaraldehyde and the 20% of the above deionized water;

[0024] 2. The stirring speed is 60r / min;

[0025] 3. After all the raw materials are added, stir for 25 minutes to obtain the bactericide for cleaning the reverse osmosis membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com