A kind of preparation method of ultra-thick energy-absorbing coating

A coating and ultra-thick technology, applied in the direction of coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of reducing the service life of blades, erosion and wear of compressor blades, etc., to achieve convenient and accurate preparation, improve The effect of low bonding strength and stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

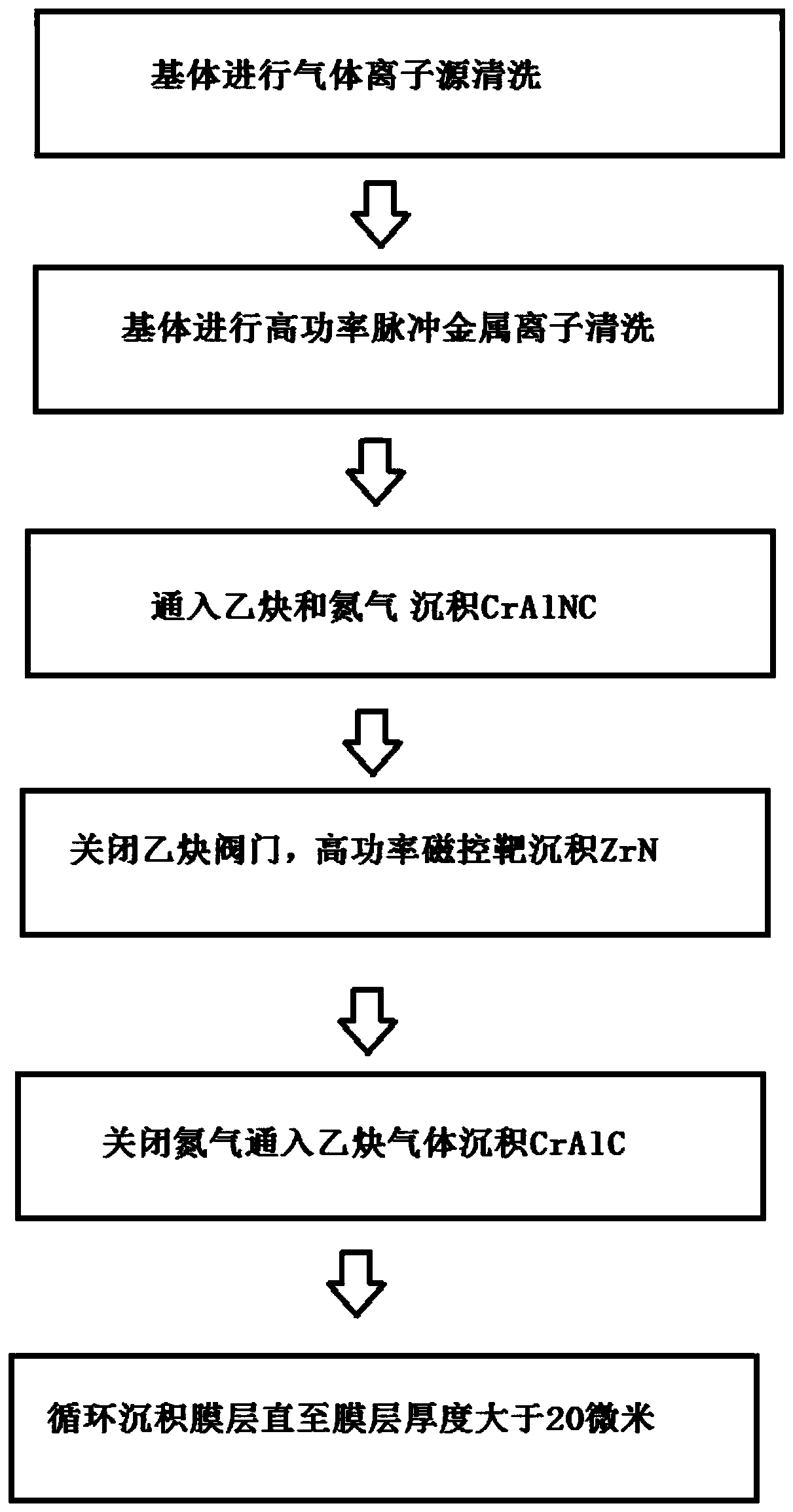

[0071] S01: cleaning the substrate with a gas ion source;

[0072] During the cleaning process of the surface gas ion source, heat treatment is carried out, and the heating temperature is 450°C. At the same time, the ion source treatment is divided into two stages; the first stage is 0-600V, beam current 2A, processing 30min, followed by 1500V, beam current 0.3A, processing 40min;

[0073] S02: The substrate is cleaned with high-power pulse metal ions;

[0074] During the high-power pulse metal cleaning process of the substrate, the metal elements to be cleaned are Ti, Cr, C, Co or Hf; the beam diameter during metal ion cleaning is 800mm.

[0075] S03: Depositing CrAlNC by feeding acetylene and nitrogen;

[0076] When depositing the film layer, the amount of acetylene and nitrogen gas is changed sinusoidally and alternately with time. Acetylene intake is 0-500sccm, nitrogen intake is 0-1000sccm, acetylene and nitrogen change sinusoidally with time, and the transient value r...

Embodiment 2

[0083] S01: cleaning the substrate with a gas ion source;

[0084] During the cleaning process of the surface gas ion source, heat treatment is carried out at a heating temperature of 480°C. At the same time, the ion source treatment is divided into two stages; the first stage is 0-600V, beam current 3A, processing 30min, followed by 1500V, beam current 0.5A, processing 40min;

[0085] S02: The substrate is cleaned with high-power pulse metal ions;

[0086] During the high-power pulse metal cleaning process of the substrate, the metal elements to be cleaned are Ti, Cr, C, Co or Hf; the beam diameter during metal ion cleaning is 800mm.

[0087] S03: Depositing CrAlNC by feeding acetylene and nitrogen;

[0088] When depositing the film layer, the amount of acetylene and nitrogen gas is changed sinusoidally and alternately with time. Acetylene intake is 0-500sccm, nitrogen intake is 0-1000sccm, acetylene and nitrogen change sinusoidally with time, and the transient value ratio...

Embodiment 3

[0095] S01: cleaning the substrate with a gas ion source;

[0096] During the cleaning process of the surface gas ion source, heat treatment is carried out, and the heating temperature is 5000C. At the same time, the ion source treatment is divided into two stages; the first stage is 0-600V, beam current 4A, processing 30min, followed by 1600V, beam current 0.8A, processing 40min;

[0097] S02: The substrate is cleaned with high-power pulse metal ions;

[0098] During the high-power pulse metal cleaning process of the substrate, the metal elements to be cleaned are Ti, Cr, C, Co or Hf; the beam diameter during metal ion cleaning is 800mm.

[0099] S03: Depositing CrAlNC by feeding acetylene and nitrogen;

[0100] When depositing the film layer, the amount of acetylene and nitrogen gas is changed sinusoidally and alternately with time. Acetylene intake is 0-500sccm, nitrogen intake is 0-1000sccm, acetylene and nitrogen change sinusoidally with time, and the transient value r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com