Stone floor pavement method

A floor and stone technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesive additives, etc., can solve the problems that affect the aesthetic effect of the home floor, the position of the stone floor is difficult to adjust, and the position of the stone floor is difficult to adjust. , to achieve the effect of improving the overall aesthetics, enhancing the anti-oxidation performance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

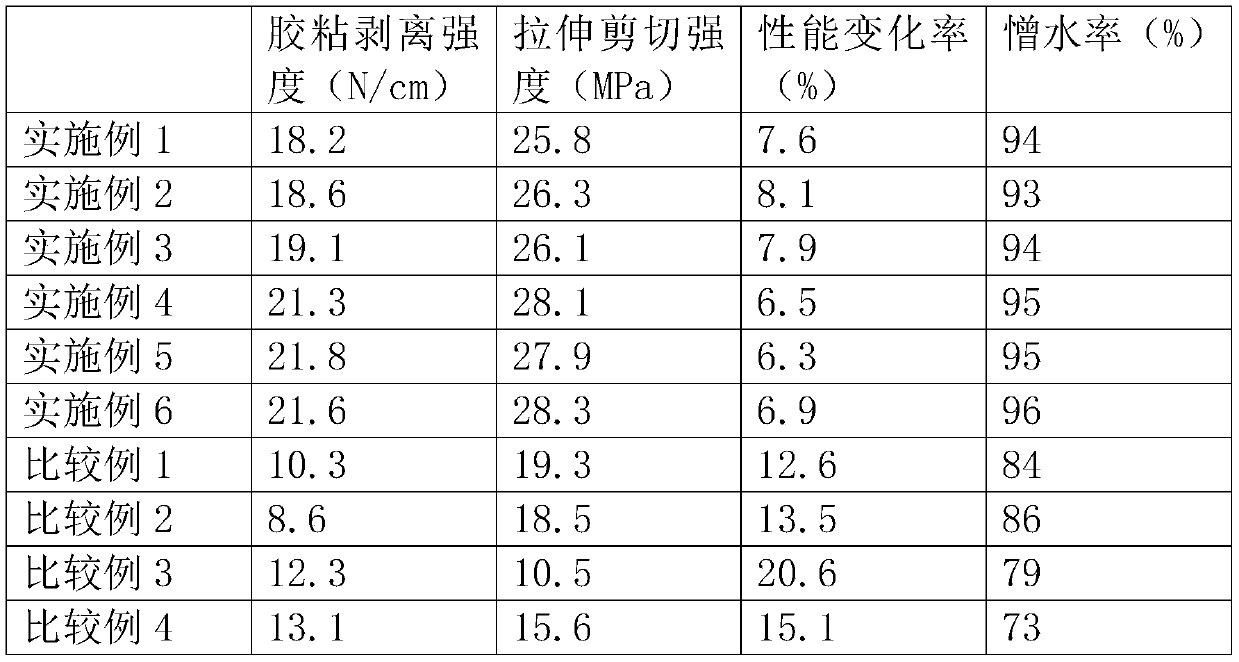

Examples

Embodiment 1

[0051] A pavement method for a stone floor is characterized in that it comprises the following steps:

[0052] S1. First clean up the rubbish on the base, then rinse the base with clean water, remove the floating soil and dust in the base, dry it, and tamp the soil of the base;

[0053] S2. Measure the size parameters of the base layer according to the design drawings, and make the corresponding elevation line on the base layer according to the design drawings with the help of a level gauge, then pour a cement mortar leveling layer on the base layer, and control the leveling of the cement mortar through the marked elevation line The height of the layer, and flatten the upper surface of the cement mortar leveling layer, so that the upper surface of the cement mortar leveling layer is horizontal;

[0054] S3. After the cement mortar leveling layer is completely solidified, according to the requirements of the design drawings, determine the laying position of the stone floor and ...

Embodiment 2

[0064] The difference with embodiment 1 is:

[0065] The length of the rubber strip is 3 / 10 of the length of the edge of the stone floor.

[0066] Wherein, adhesive comprises the component of following mass parts:

[0067] Acrylic glue 55kg; polyurethane glue 15kg; polyvinylpyrrolidone 3kg; fatty alcohol polyoxyethylene ether 1kg; walnut shell powder 0.5kg; paraffin wax 0.3kg.

[0068] The preparation method of adhesive is as follows:

[0069] In a 100L stirred tank, under normal temperature, add 55kg of acrylate glue and 15kg of polyurethane glue, stir at a speed of 40r / min, add 3kg of polyvinylpyrrolidone, 1kg of fatty alcohol polyvinyl ether, 0.5kg of walnut shell powder, 0.3 kg of paraffin, stirred for 15 minutes to form a mixture, and then put the mixture into a screw extruder for hot-melt extrusion to obtain an adhesive.

Embodiment 3

[0071] The difference with embodiment 1 is:

[0072] The length of the rubber strip is 2 / 5 of the length of the edge of the stone floor.

[0073] Wherein, adhesive comprises the component of following mass parts:

[0074] Acrylic glue 53kg; polyurethane glue 18kg; polyvinylpyrrolidone 1kg; fatty alcohol polyoxyethylene ether 2kg; walnut shell powder 0.8kg; paraffin wax 0.1kg.

[0075] The preparation method of adhesive is as follows:

[0076] In a 100L stirred tank, under normal temperature conditions, add 53kg of acrylate glue and 18kg of polyurethane glue, stir at a speed of 40r / min, add 1kg of polyvinylpyrrolidone, 2kg of fatty alcohol polyvinyl ether, 0.8kg of walnut shell powder, 0.1 kg of paraffin, stirred for 15 minutes to form a mixture, and then put the mixture into a screw extruder for hot-melt extrusion to obtain an adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com