A core fiber for heat-not-burn cigarettes and its application

A heat-not-burn, cigarette core technology, applied in applications, smoker supplies, tobacco, etc., can solve the problems of smoke loss, cigarette paper impregnation, etc., and achieve the effect of preventing impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation of the loaded material is to immerse the porous loaded material in the microcapsule aqueous solution, and after stirring for 1-2 hours, filter, wash, and then dry at a low temperature below 50° C. to obtain the loaded material. The weight ratio of the specific porous loading material to the microcapsules is determined by the concentration of the aqueous solution of the microcapsules and the soaking time. The weight ratio is relatively large, such as 1:3; if the aqueous solution concentration of the microcapsules is low and the soaking time is short, the weight ratio of the porous loading material and the microcapsules in the prepared loading material is small, such as 10:1, and the specific weight ratio is based on needs Prepare and measure.

[0029] In the technical solution of the present application, the microcapsule wall material includes natural polymer materials, semi-synthetic polymer materials or fully synthetic polymer materials.

[0030] The m...

Embodiment 1

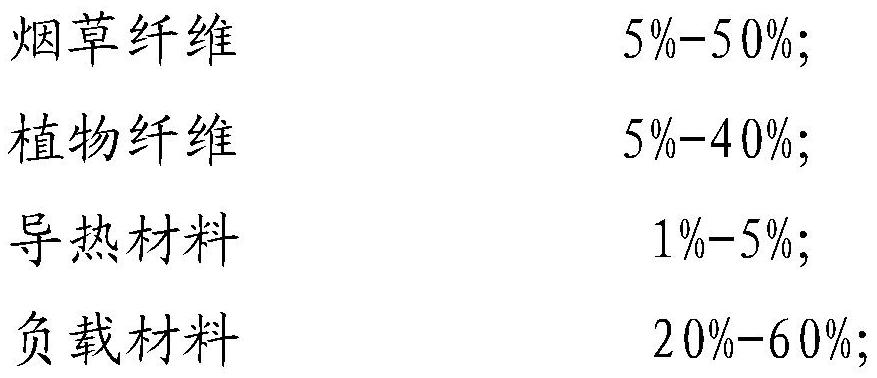

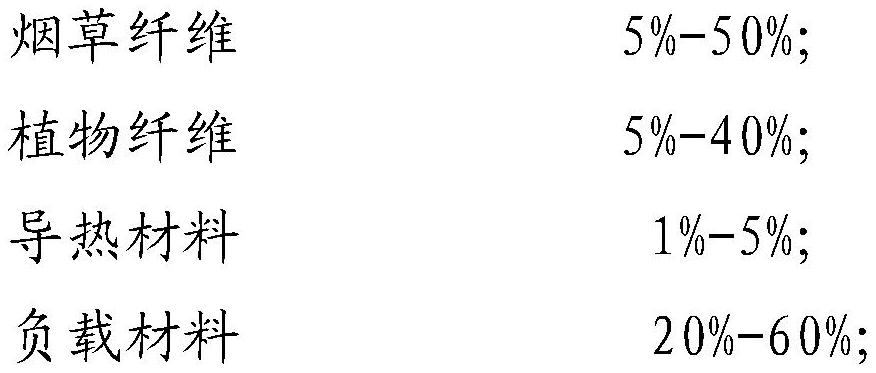

[0032] A core fiber for heat-not-burn cigarettes, the components and weight percentages of which are:

[0033] 10% tobacco fiber, 40% wood pulp fiber, 45% load material, 5% carbon fiber; the load material is composed of zeolite and microcapsules adsorbed in the zeolite; the weight ratio of porous load material to microcapsule is 10: 1. The particle size of the microcapsules is 50 μm-150 μm.

[0034] The tobacco fiber is a 50-300 mesh fibrous tobacco material formed by crushing tobacco leaves and tobacco stems as raw materials. The core materials of the microcapsules are tobacco extract and smoking agent.

[0035] After the above-mentioned components are prepared into slurry, the cigarette core fiber is prepared by silk-making method, and the cigarette core fiber can be in sheet structure, cylinder structure or polygonal column structure. One or more of the above-mentioned cigarette core fibers are mixed and prepared into bundles, which are used to prepare cigarette cores of...

Embodiment 2

[0037] A core fiber for heat-not-burn cigarettes, the components and weight percentages of which are:

[0038] 20% tobacco fiber, 20% wood pulp fiber, 59% load material and 1% carbon fiber; the load material is composed of zeolite and microcapsules adsorbed in the zeolite; the weight ratio of porous load material to microcapsule is 10: 1. The particle size of the microcapsule is 50μm-150μm.

[0039] The tobacco fiber is a 50-300 mesh fibrous tobacco material formed by pulverizing tobacco leaves, shredded tobacco, tobacco dust, tobacco stems, reconstituted tobacco leaves and tobacco stalks. The core materials of the microcapsules are tobacco extract and smoking agent.

[0040] After the above-mentioned components are prepared into slurry, the cigarette core fiber is prepared by silk-making method, and the cigarette core fiber can be in sheet structure, cylinder structure or polygonal column structure. One or more of the above-mentioned cigarette core fibers are mixed and prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com