Fermentation broth pulping machine

A technology of pulping machine and fermentation liquid, applied in grain processing and other directions, can solve the problems of poor beating effect and low beating efficiency, and achieve the effects of constant load, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

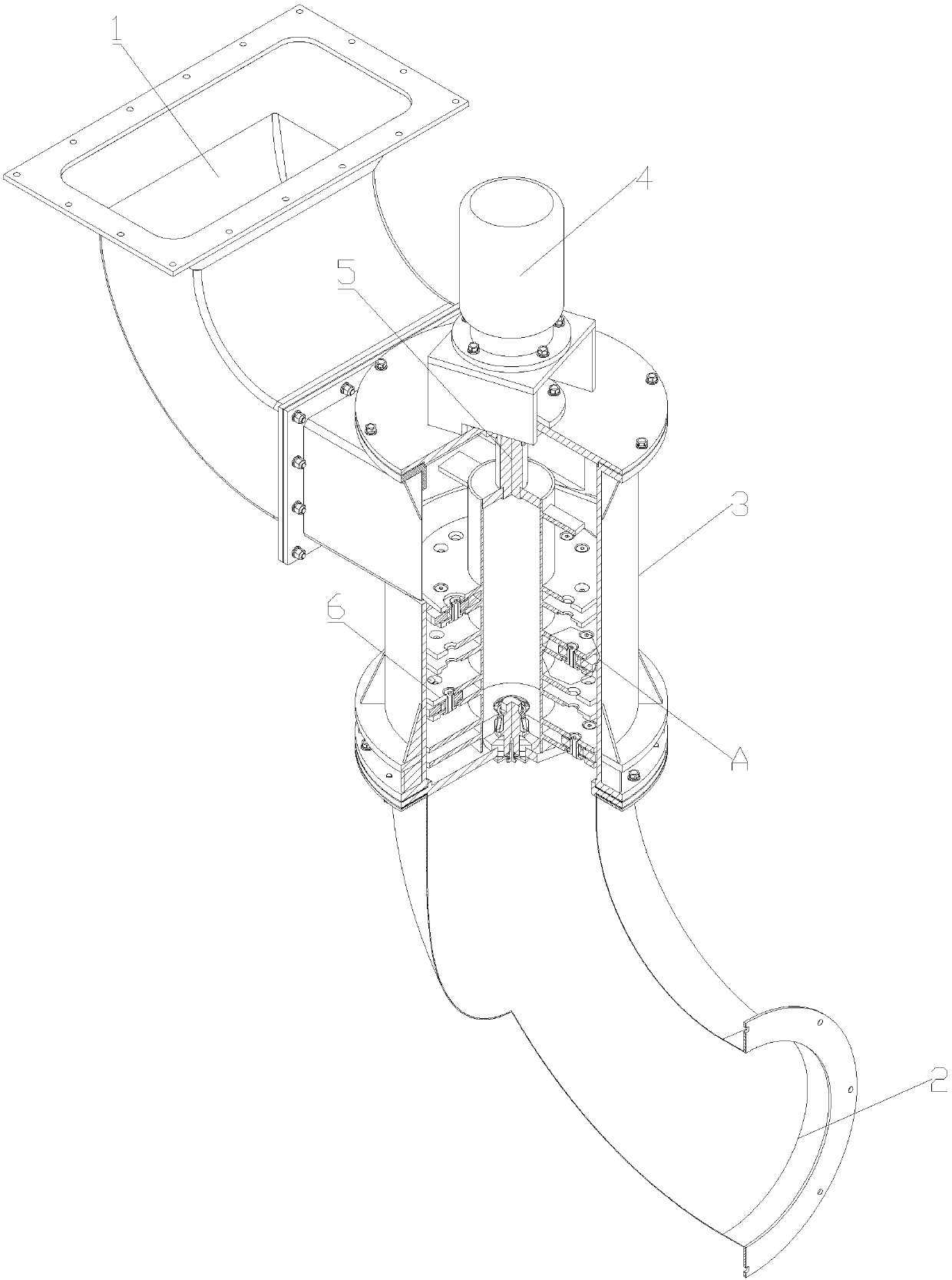

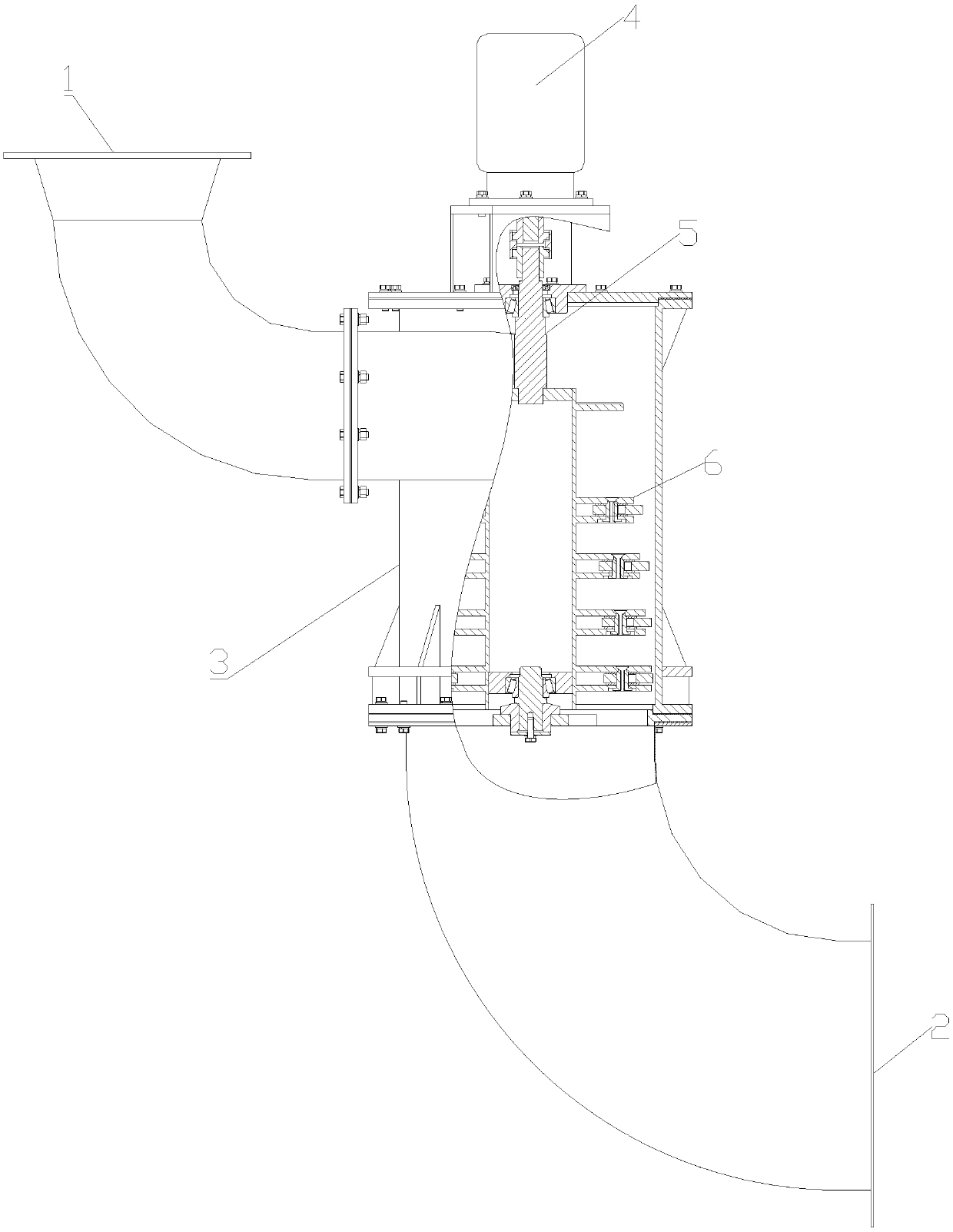

[0024] Such as Figure 1-3 As shown, a fermented liquid pulping machine includes a feed port 1, a discharge port 2 and a beating barrel 3;

[0025] A motor 4 is fixedly installed on the top of the beating barrel 3, and a rotating shaft 5 is arranged in the beating barrel 3, and the top of the rotating shaft 5 is connected with the power output end of the motor 4, and a rotating roller is installed on the bottom of the rotating shaft 5, and a rotating roller is fixed on the rotating roller. A movable cutter head 6 is installed;

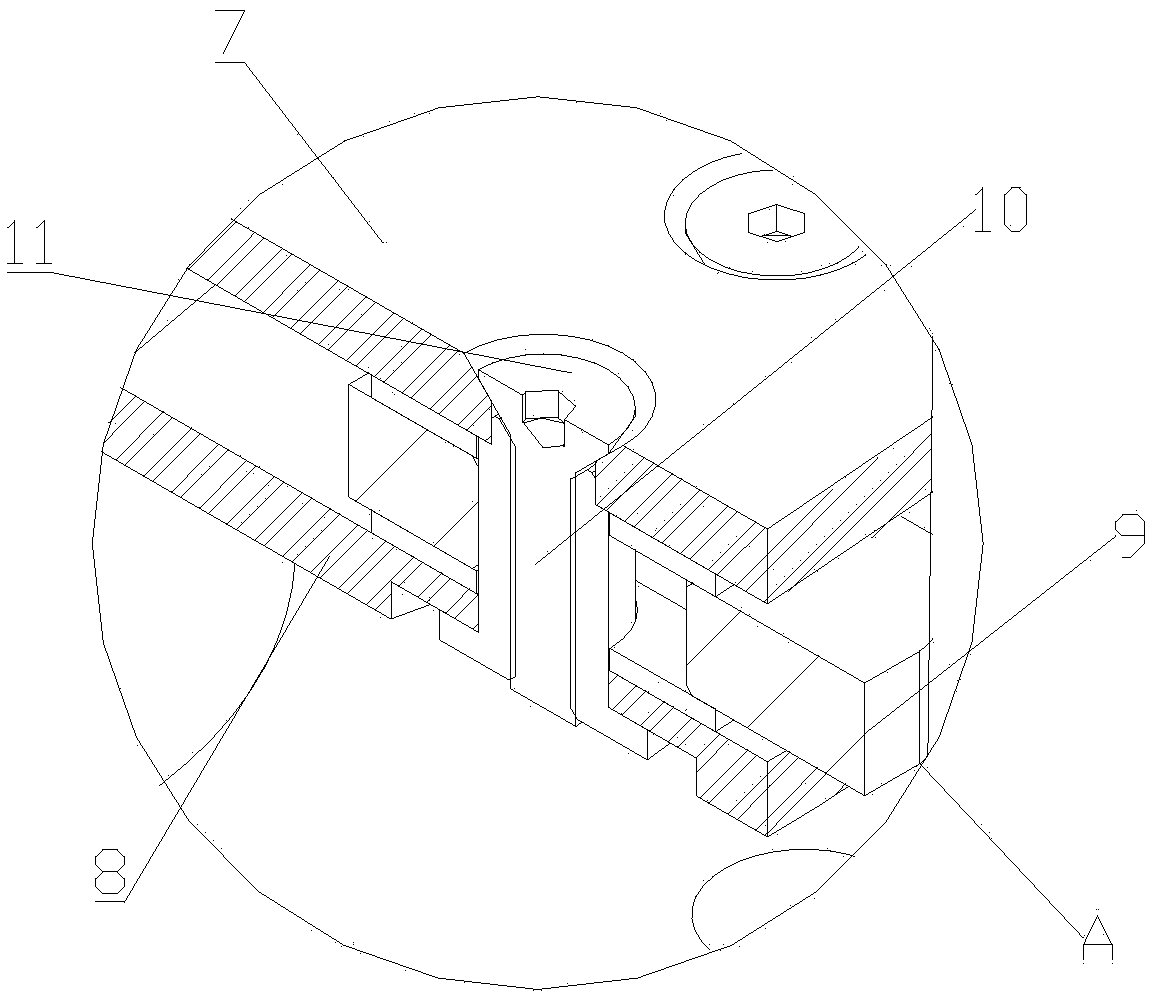

[0026] The movable cutter head 6 is composed of an upper crushing blade 7 and a lower crushing blade 8, the upper crushing blade 7 and the lower crushing blade 8 are fixedly connected to the rotating roller, and the upper crushing blade 7 and the lower crushing blade 8 There is a mounting hole 11 on the top, and a mounting column 10 is installed between the mounting holes 11 of the upper crushing blade 7 and the following crushing blade 8, and a crush...

Embodiment 2

[0029] Such as Figure 1-3 As shown, a fermented liquid pulping machine, on the basis of Example 1, the upper side of the beating barrel 3 is provided with a feed inlet 1, and the bottom of the beating barrel 3 is provided with a discharge port 2, and the feed port 1 It communicates with the discharge port 2 and the beating barrel 3;

[0030] The beating barrel 3 is a three-dimensional cylindrical structure;

[0031] The number of the movable cutter head 6 is multiple, and the distance between the crushing blade 9 moved to the final position and the beating barrel 3 due to the centrifugal force decreases successively from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com