Vertical vehicle workpiece loading machine

A technology for workpieces and vehicles, which is applied in the field of loading machinery for vertical vehicle workpieces, and can solve problems such as low manual operation efficiency, physical damage to workers, and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

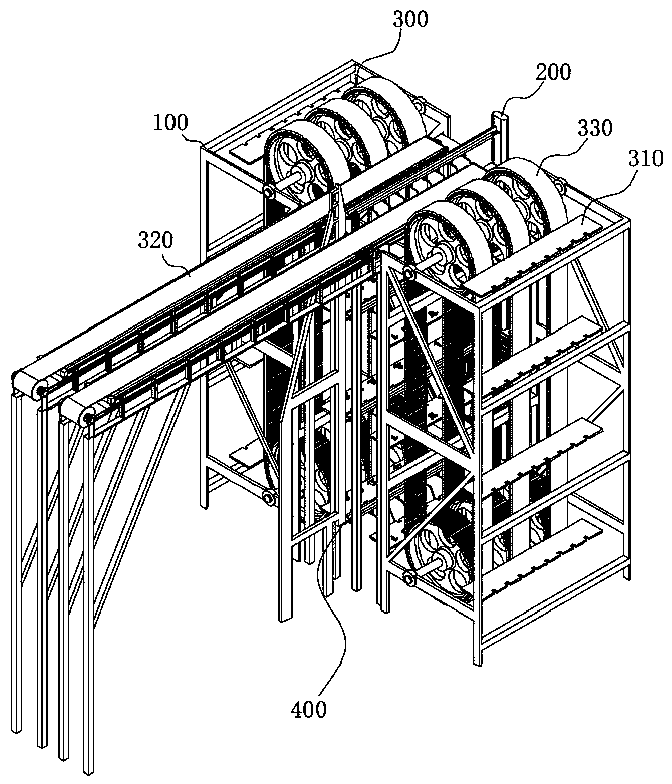

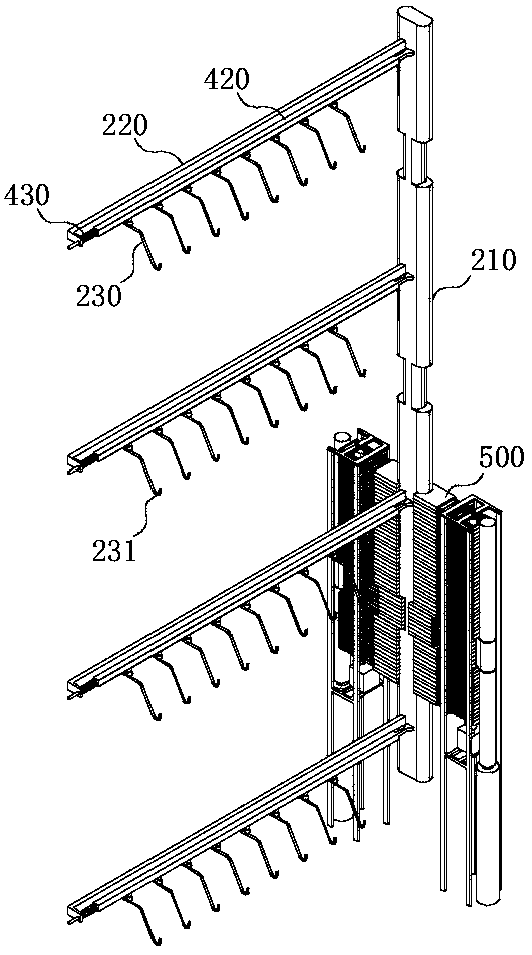

[0055] refer to Figure 1-5 , in an embodiment of the present invention, a loading machine for vertical vehicle workpieces is proposed, which includes a guiding device 500 for guiding the hanger 200 and an assembly device 300 for hooking the workpiece to the hanger 200. The frame 200 includes an assembly rod 210, a hanging rod 220 arranged at intervals on the assembly rod 210, and a hook assembly 230 for hooking workpieces. The assembly rod 210 and the hanging rod 220 are arranged in an intersecting shape, and the hook assembly 230 is movably installed on the hanger 200;

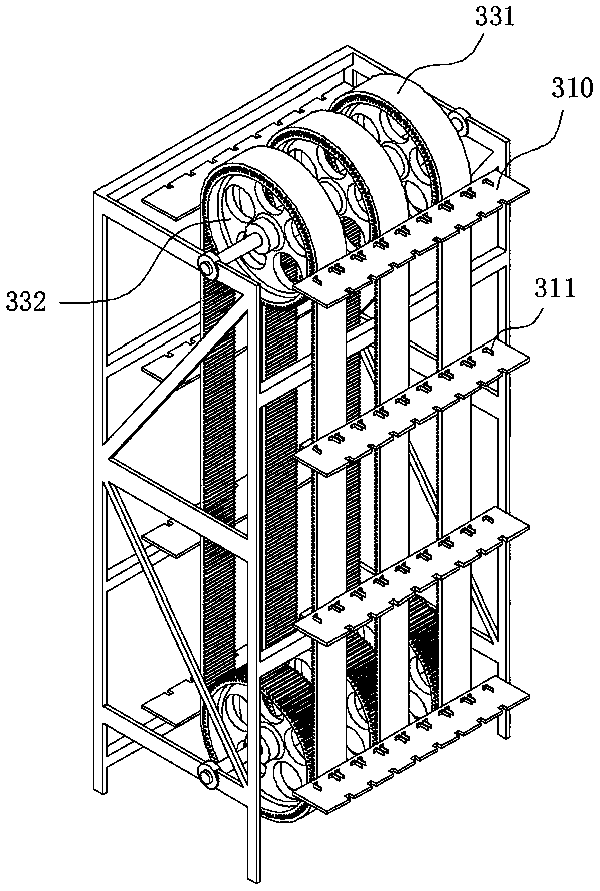

[0056] The assembly device 300 includes a material supporting part 310 for supporting the workpiece, a material distribution mechanism 320 for arranging the workpiece on the material supporting part 310, and a conveying mechanism 330 for adjusting the reciprocating movement of the material supporting part 310 up and down. rod 220 outside;

[0057] It also includes an adjustment mechanism 400 for adjusting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com