A kind of shaped sponge cushion with different hardness and preparation method thereof

A technology of hardness and sponge, which is applied in the field of different hardness shaped sponge cushions and its preparation, which can solve the problems of various raw material ingredients, failure to realize multiple hardness changes of cushions, and inability to effectively fit the human body sitting posture curve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

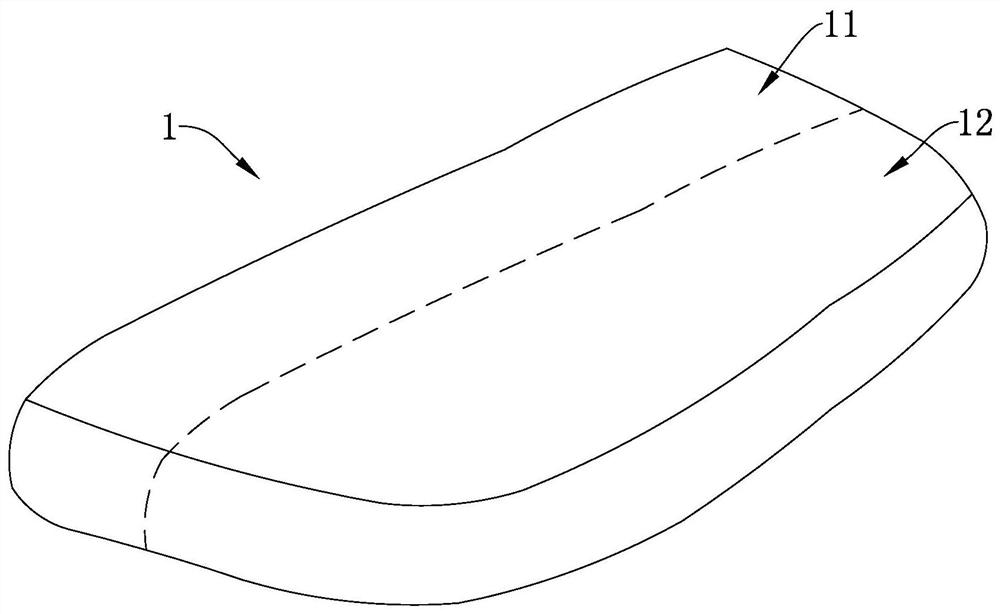

[0044]A kind of different hardness setting sponge cushion, such as figure 1 As shown, the sponge cushion 1 is divided into two different hardness regions (region a11, region b12) before and after;

[0045] In area a11:

[0046] Component A comprises the following raw materials by weight percentage:

[0047]

[0048] Component B comprises the following raw materials by weight percentage:

[0049] Isocyanate 17%;

[0050] The weight ratio of the A component and the B component is 83:17.

[0051] In zone b12:

[0052] Component A comprises the following raw materials by weight percentage:

[0053]

[0054] Component B comprises the following raw materials by weight percentage:

[0055] Isocyanate 26%;

[0056] The weight percentage of the A component and the B component is 37:13.

[0057] Wherein, the polyether polyol is SA34-05, its molecular weight is 5000; the polymer polyol is KGP-524, its molecular weight is 2300-3500; the isocyanate is MDI 2412; glue catalyst...

Embodiment 2

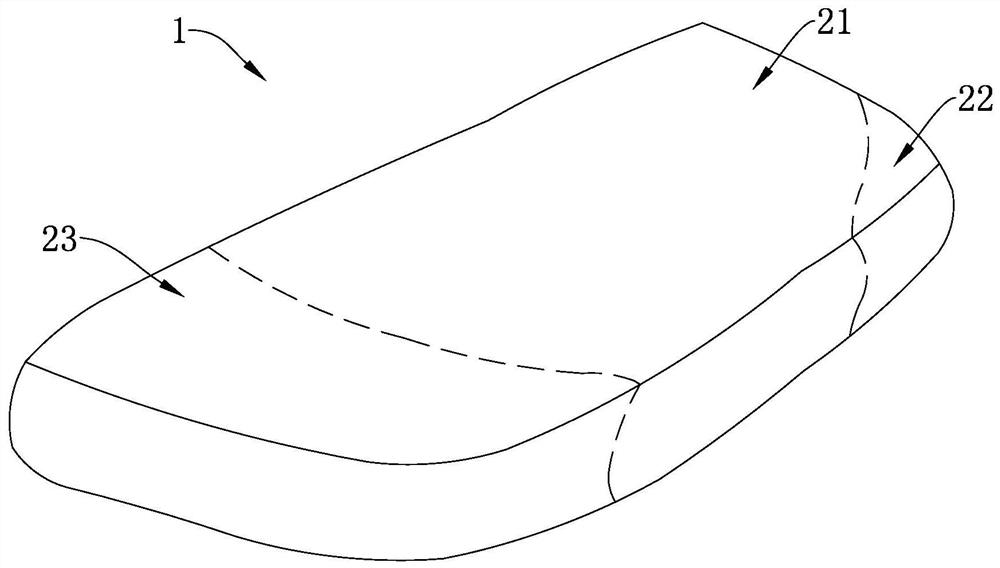

[0073] A kind of different hardness setting sponge cushion, such as figure 2 As shown, the sponge cushion 1 is divided into three different hardness regions (region c21, region d22, region e23);

[0074] In zone c21:

[0075] Component A comprises the following raw materials by weight percentage:

[0076]

[0077] Component B comprises the following raw materials by weight percentage:

[0078] Isocyanate 19%;

[0079] The weight percentage of the A component and the B component is 81:19.

[0080] In zone d22:

[0081] Component A comprises the following raw materials by weight percentage:

[0082]

[0083] Component B comprises the following raw materials by weight percentage:

[0084] Isocyanate 25%;

[0085] The weight percentage of the A component and the B component is 3:1.

[0086] In zone e23:

[0087] Component A comprises the following raw materials by weight percentage:

[0088]

[0089] Component B comprises the following raw materials by weight p...

Embodiment 3

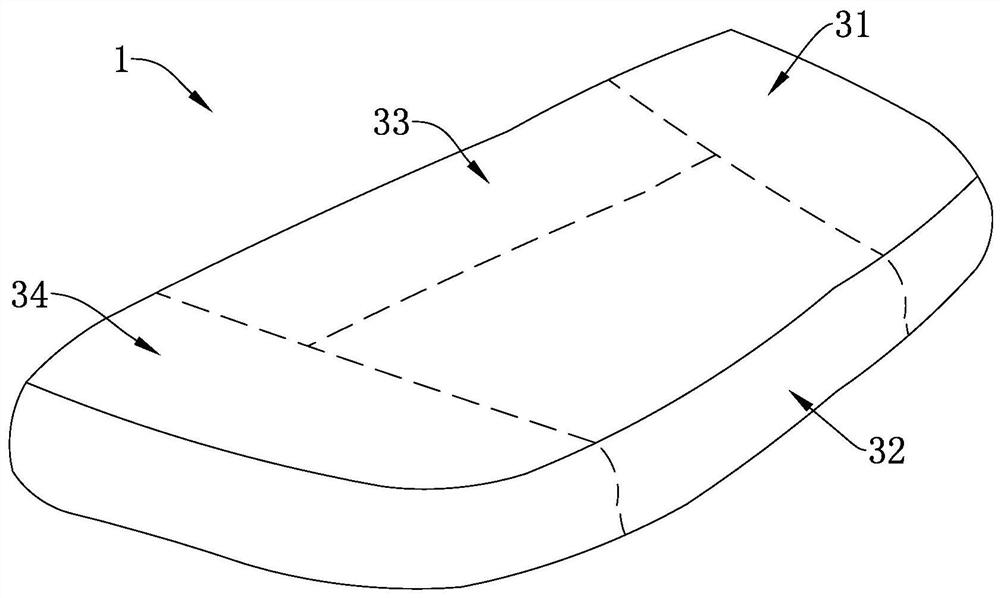

[0107] A kind of different hardness setting sponge cushion, such as image 3 As shown, the sponge cushion 1 is divided into four regions with different hardness (region f31, region g32, region h33, region i34);

[0108] In area f31:

[0109] Component A comprises the following raw materials by weight percentage:

[0110]

[0111]

[0112] Component B comprises the following raw materials by weight percentage:

[0113] Isocyanate 23%;

[0114] The weight percentage of the A component and the B component is 77:23.

[0115] In zone g32:

[0116] Component A comprises the following raw materials by weight percentage:

[0117]

[0118] Component B comprises the following raw materials by weight percentage:

[0119] Isocyanate 24%;

[0120] The weight percentage of the A component and the B component is 19:6.

[0121] In zone h33:

[0122] Component A comprises the following raw materials by weight percentage:

[0123]

[0124] Component B comprises the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com