Cold spraying construction method for waterborne uncured asphalt waterproof coating

A kind of asphalt waterproof coating and construction method technology, applied in the direction of building insulation materials, building components, covering/lining, etc., can solve the problem that the quality of the waterproof layer is greatly affected by construction factors, safety and environmental protection are difficult to meet, and the coating thickness is uniform Problems such as difficult to control, to achieve good waterproof effect, shorten the construction period, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

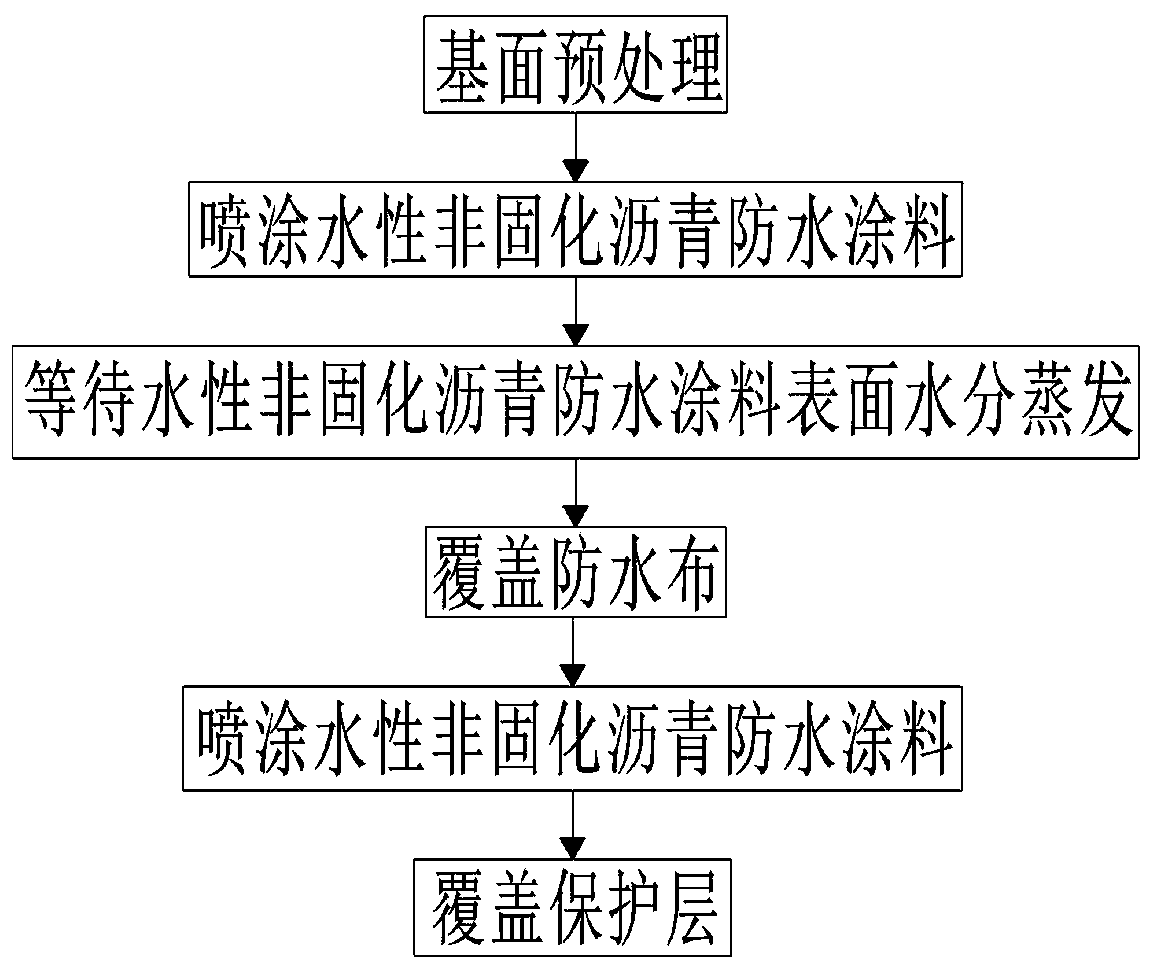

[0021] Such as figure 1 As shown, the present invention discloses a cold spraying construction method of water-based non-curable asphalt waterproof coating. The cold spray construction method mainly includes the following steps: step 1 base surface pretreatment, step 2 spraying water-based non-curable asphalt waterproof coating, Step 3 waits for the water-based non-curable bitumen waterproof coating to evaporate, step 4 covers the waterproof cloth, step 5 sprays the water-based non-curable bitumen waterproof coating, and step 6 covers the protective layer.

[0022] Taking the on-site construction of polyethylene polypropylene tarpaulin covered by the middle layer as an example, the construction process is explained in detail:

[0023] Step 1 Base surface pretreatment: remove the base surface sundries, floating soil and dust, if the base surface is dusty, it must be wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com