Bolt connecting structure of assembled reinforced concrete shear wall and manufacturing method thereof

A reinforced concrete and connecting structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of cumbersome construction process, application obstacles, weak energy consumption capacity, etc., to improve construction efficiency, reduce construction difficulty, optimize The effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

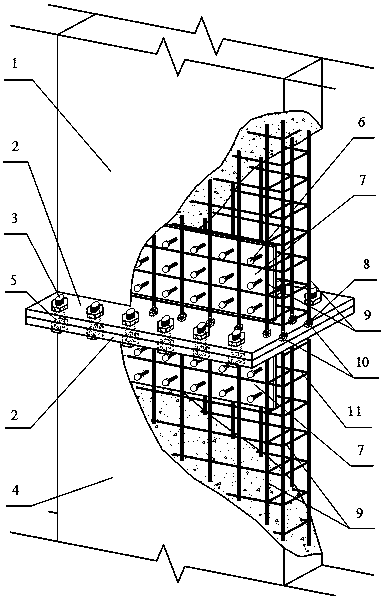

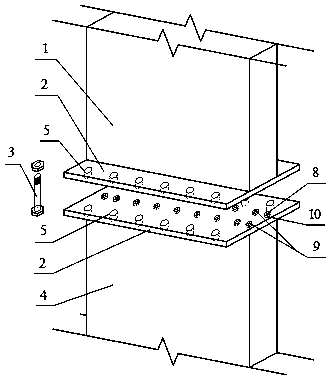

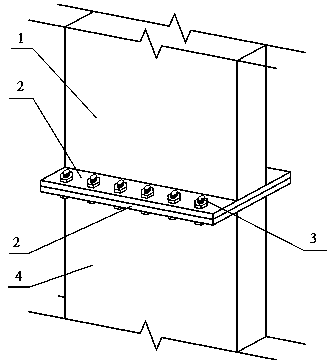

[0032] refer to Figure 1-3 , a prefabricated reinforced concrete shear wall bolt connection structure, comprising an upper layer prefabricated reinforced concrete wall 1 and a lower layer prefabricated reinforced concrete wall 4, between the upper layer prefabricated reinforced concrete wall 1 and the lower layer prefabricated reinforced concrete wall 4 It is a pre-embedded T-shaped connector wing plate 2 with pre-drilled bolt holes 5 .

[0033] The upper layer prefabricated reinforced concrete wall and the lower layer prefabricated reinforced concrete wall have the same structure and are arranged symmetrically.

[0034] refer to Figure 4 , the upper prefabricated...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap