Hydraulic high-frequency impact device for drilling stuck release

A hammer and hydraulic technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of drill sticking and high difficulty in unblocking, so as to improve work efficiency, simplify wellhead operation procedures and save operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

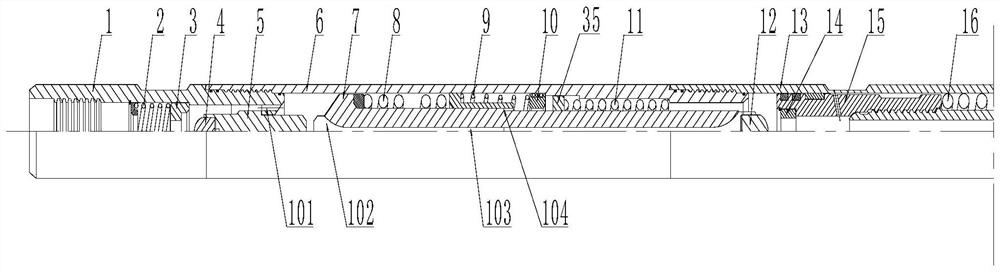

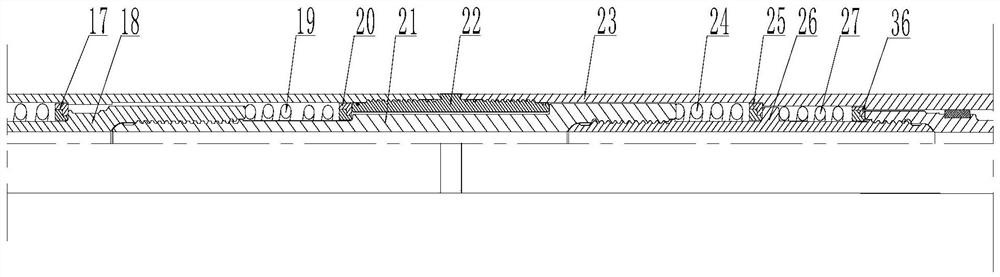

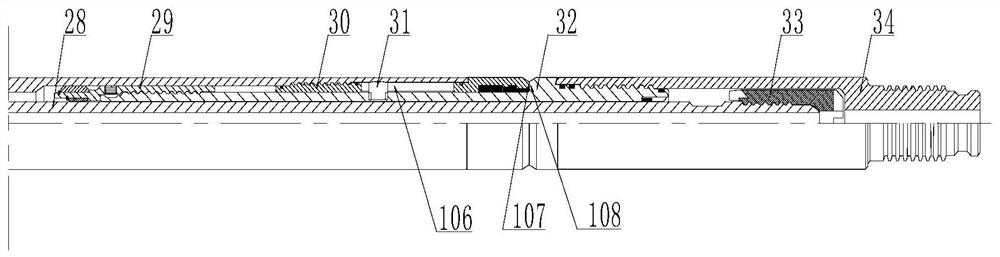

[0034] The hydraulic high-frequency impactor for drilling and unblocking is composed of four major assemblies: valve assembly, downstroke piston assembly, upstroke piston assembly, and force transmission assembly. in:

[0035] Such as Figure 1-6 As shown, the valve assembly is mainly composed of: an upper joint 1, a valve spring 2, a valve seat 3, a valve head 4, and a valve stem 5.

[0036] The downstroke piston assembly is mainly composed of: upper outer cylinder 6, downstroke piston 7, downstroke primary spring 8, downstroke secondary spring 11, lifting spring 9, support ring 10, limit ring 35, and downstroke piston valve Head 12 composition.

[0037] The upper stroke piston assembly is mainly composed of: middle outer cylinder 13, lower outer cylinder 23, intermediate joint 22, sealing seat 14, upper stroke piston 15, upper stroke first-stage spring 16, upper stroke second-stage spring 19, upper stroke third-stage spring 24 , upper stroke four-stage spring 27, upper ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com