Gas particulate traps and vehicle exhaust particulate traps

A particle trap, motor vehicle technology, applied in machine/engine, chemical instruments and methods, mechanical equipment, etc., can solve problems such as increasing engine back pressure and fuel consumption, and achieve improved reliability, reduced back pressure, and space adaptation. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

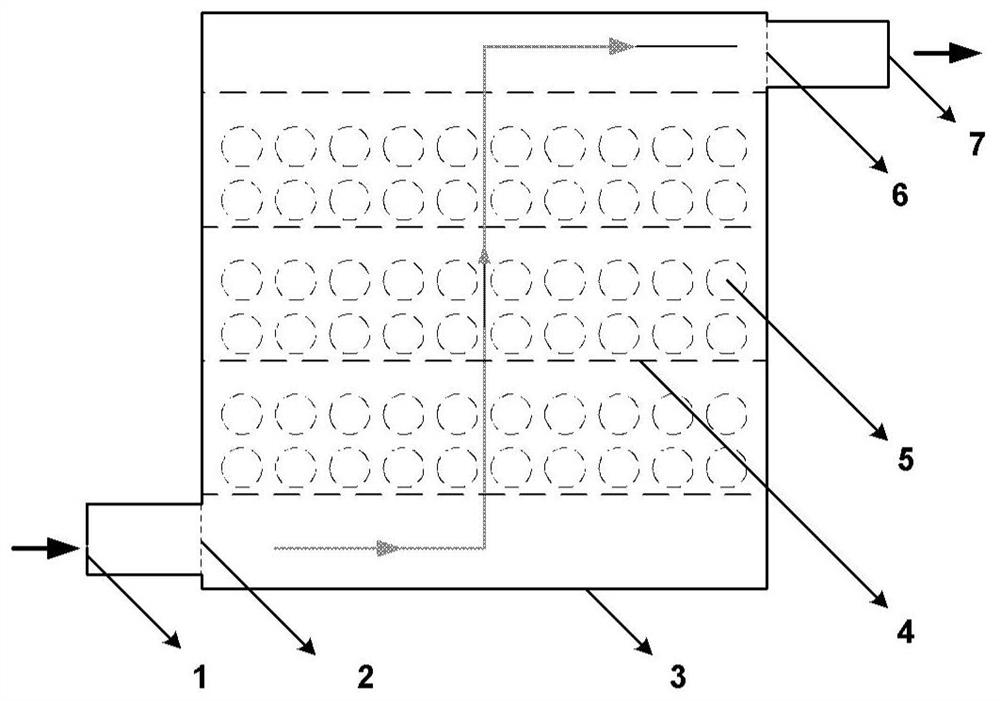

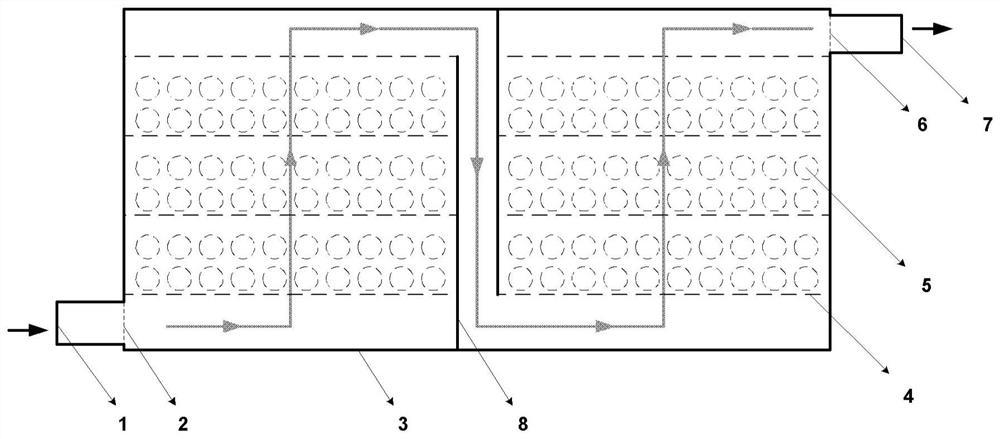

[0030] The present disclosure provides a particulate matter trap in gas, especially a particulate matter trap for motor vehicle exhaust. Common frictional electrification materials have a low melting point and are difficult to use in the purification environment of motor vehicle exhaust gas, and at the same time improve the utilization of materials in the process of triboelectrification Efficiency, thereby improving the particle capture efficiency. The motor vehicle exhaust particle trap of the present disclosure adopts temperature-resistant materials such as silicon oxide, cordierite, mica, ceramics, etc. According to the temperature requirements of the motor vehicle emission environment, the above-mentioned one or more materials are made into particles with a diameter of 1-5mm, and they are put into the cavity structure of the motor vehicle exhaust particulate filter to form a triboelectric particulate filter. The triboelectric particle filter is installed on the motor vehic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com