Direct-current layered scavenging two-stroke engine

An engine and two-stroke technology, which is applied in the field of DC stratified scavenging two-stroke engines, can solve the problems of increased engine height and complex ventilation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

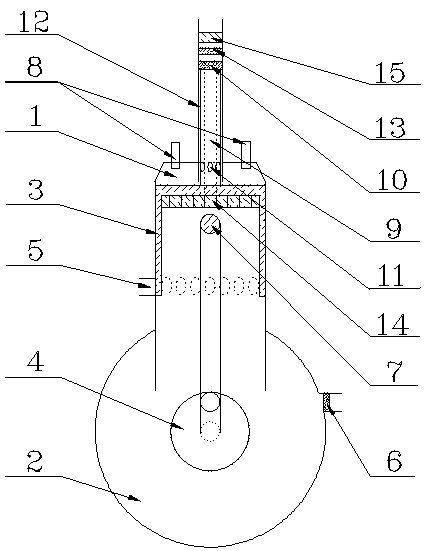

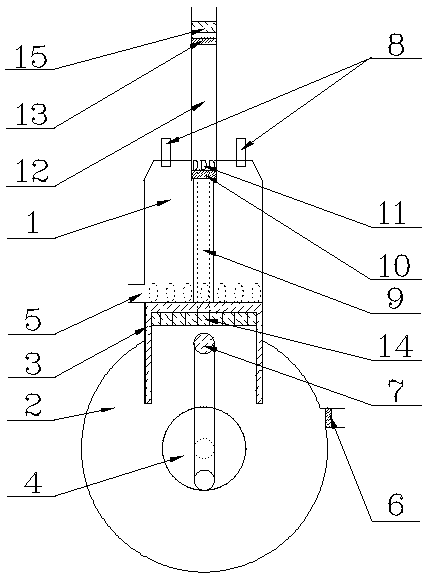

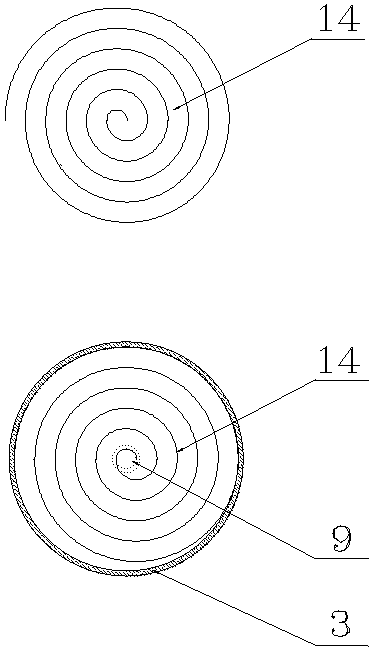

[0015] as attached figure 1 , attached figure 2 , attached image 3 In the described embodiment, the two-stroke engine DC layered scavenging structure includes cylinder block 1, crankcase 2, piston 3, crankshaft flywheel set 4, exhaust port 5, main air inlet reed valve 6, piston pin 7. Spark plug 8, main scavenging channel tube 9, main scavenging channel port 10, scavenging port 11, secondary scavenging channel tube 12, secondary air inlet reed valve 13, gas storage spiral coil 14, throttle valve 15. There is a combustion chamber for installing the piston 3 inside the cylinder block 1, and the main scavenging channel pipe 9 is arranged in the center of the top of the piston, perpendicular to the top of the piston, on the central axis of the cylinder or parallel to the axis, and the upper part of the main scavenging channel pipe port 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com