Damping oil outlet of VE distribution pump and application method of damping oil outlet valve

A technology for oil delivery valves and distribution pumps, applied to fuel injection pumps, engine components, machines/engines, etc., which can solve problems such as high manufacturing costs, small stopper diameters, and small size of oil delivery valves, and achieve smooth oil passages , Reduce use failure, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout.

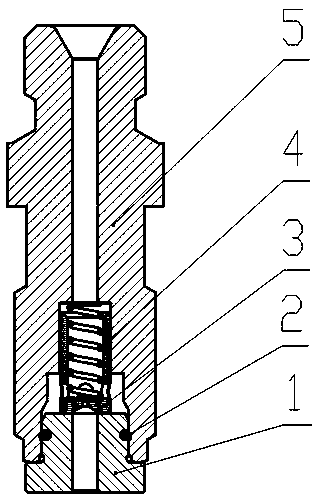

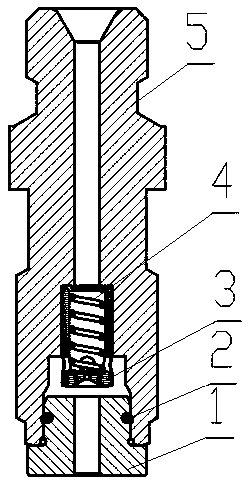

[0024] Such as figure 1 Shown is a damping oil outlet valve of a VE distribution pump, which includes a tubular oil outlet valve tight seat 5 with protrusions on the outside of the oil outlet valve tight seat 5 for connecting with the pump body. The end of the tight seat 5 of the oil outlet valve has a step hole, and a valve core 3 is arranged in the step hole, and the opening of the step hole is connected to the oil outlet valve seat 1 through a retaining spring 2, and the center of the oil outlet valve seat 1 has a through hole.

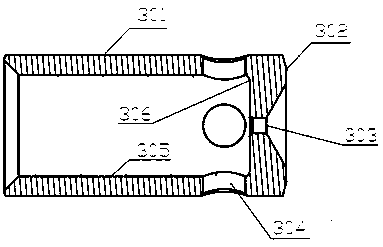

[0025] Such as image 3 As shown, the spool 3 includes a columnar core body 301, a guide hole 305 is provided at the center of one end of the core body 301, a throttling small hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com