High-sensitivity hydrogen sensor at room temperature and preparation method thereof

A sensor and hydrogen technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of inconvenient application, and achieve the effect of easy operation, convenient use and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

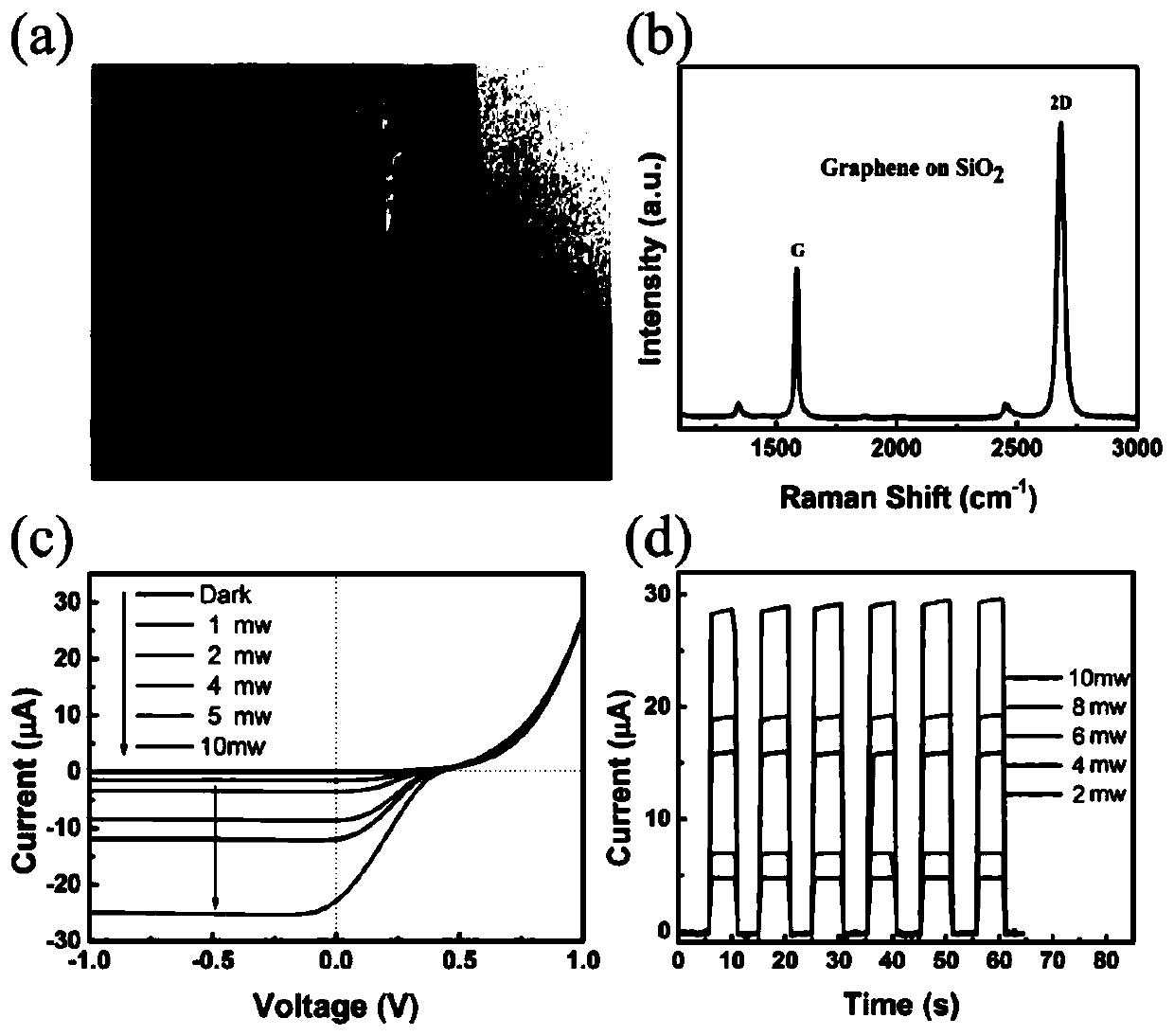

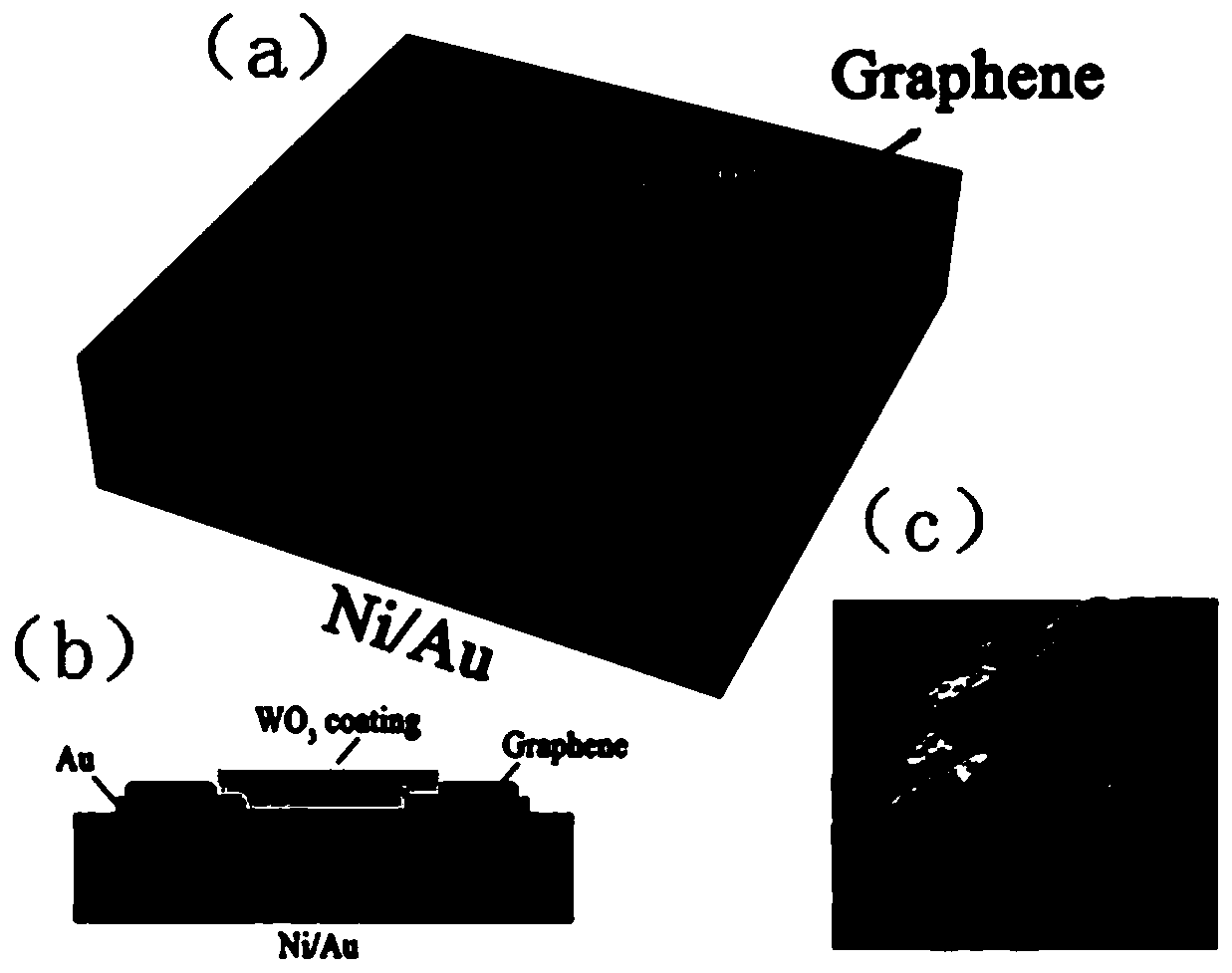

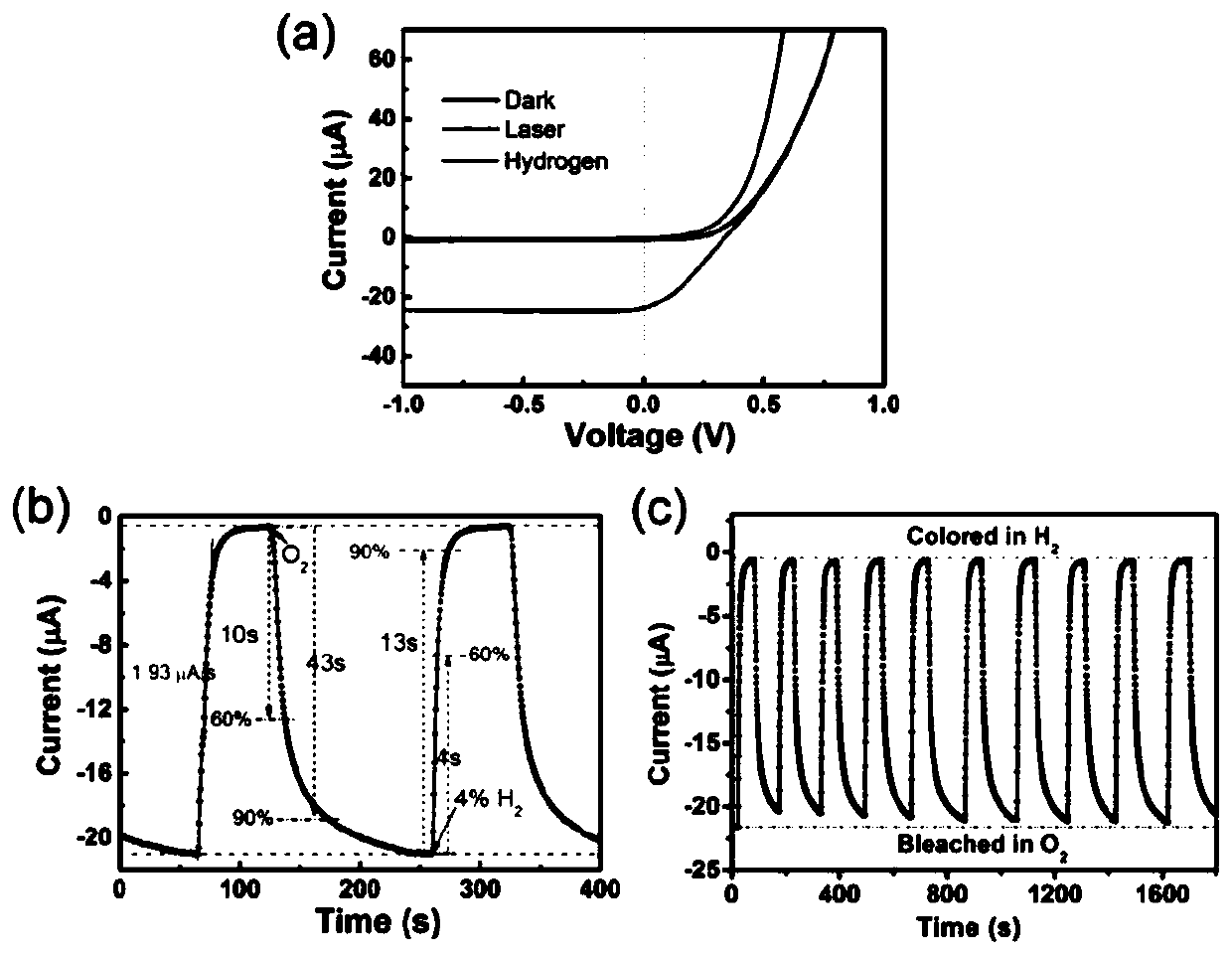

Embodiment 1

[0042] A high-sensitivity hydrogen sensor at room temperature comprises a substrate and a hydrogen sensitive layer in sequence, and the hydrogen sensitive layer is a palladium-doped tungsten trioxide thin film. Further, in this embodiment, the preferred substrate is a graphene / Si heterostructure Schottky junction composed of n-type silicon wafer and graphene. The thickness of the hydrogen sensitive layer is generally 20-200 nm. In this embodiment, the thickness of the hydrogen sensitive layer is selected to be 100 nm. In the hydrogen sensitive layer, the molar ratio Pd:W=1:50. The resistivity of the n-type silicon wafer is 1-10Ω·cm, and the graphene is single-layer graphene.

[0043] The preparation method of the above-mentioned highly sensitive hydrogen sensor at room temperature comprises the following steps:

[0044] S1: Fabrication of graphene / Si heterostructure Schottky junction:

[0045] S1-1: Etching the silicon dioxide on the surface of the n-type silicon wafer to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com