Power battery pack and electric vehicle

A technology for power battery packs and electric vehicles, applied in the field of electric vehicles, can solve the problems of reducing the utilization rate of the inner space of the pack body 200″, the adverse effects of the quality of the power battery packs, and the stability of the power battery packs, etc., so as to improve the battery life. , the effect of increasing space utilization and expanding battery space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

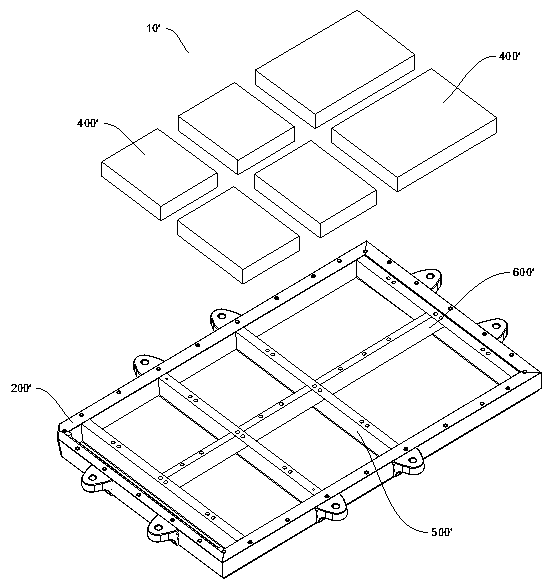

[0194] According to the power battery pack 10 of the embodiment of the present application, such as Figure 12 As shown, the length direction of the single battery 100 is arranged along the width direction B of the power battery pack, and a plurality of single cells 100 are arranged along the length direction A of the power battery pack 10. In the width direction B of the power battery pack, the package body 200 Two single cells 100 are accommodated. A width direction beam 500 and a length direction beam 600 are arranged inside the package body 200 , the width direction beam 500 extends along the width direction B of the power battery pack 10 , and a plurality of single cells 100 are arranged along the length direction A of the power battery pack 10 to form Battery array, width direction beam 500 divides the battery array into two parts along the length direction A of the power battery pack 10 . In addition, the plurality of single batteries 100 are arranged in two rows of ba...

Embodiment 2

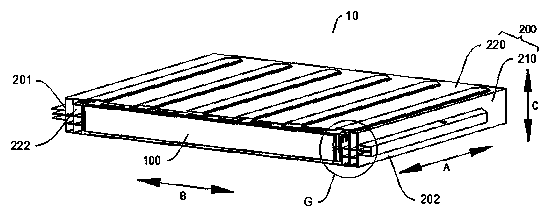

[0196] According to the power battery pack 10 of the embodiment of the present application, such as Figure 13 As shown, the length direction of the single battery 100 is arranged along the width direction B of the power battery pack, and a plurality of single cells 100 are arranged along the length direction A of the power battery pack 10. In the width direction B of the power battery pack, the package body 200 A single battery 100 is accommodated, and the single battery 100 extends from one side of the package body 200 to the other side in the width direction B of the power battery pack 10 . A transverse beam 500 in the width direction is arranged inside the package body 200, and the transverse beam 600 in the longitudinal direction is not provided. The transverse beam 500 in the width direction extends along the width direction B of the power battery pack 10, and a plurality of single cells 100 are arranged along the length direction A of the power battery pack 10. A batter...

Embodiment 3

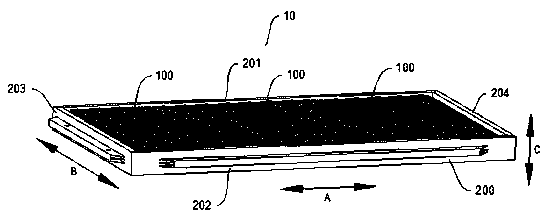

[0198] According to the power battery pack 10 of the embodiment of the present application, such as Figure 14 As shown, the length direction of the single battery 100 is arranged along the width direction B of the power battery pack, and a plurality of single cells 100 are arranged along the length direction A of the power battery pack 10. In the width direction B of the power battery pack, the package body 200 A single battery 100 is accommodated, and the single battery 100 extends from one side of the package body 200 to the other side in the width direction B of the power battery pack 10 . The transverse beam 500 in the width direction and the transverse beam 600 in the longitudinal direction are not provided in the enclosure 200 . The first beam 201 and the second beam 202 of the package body 200 located on both sides of the power battery pack 10 in the width direction B provide support for the single battery 100 , and the third beams of the package body 200 located at bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com