Manufacturing method of mnal alloy

A manufacturing method and alloy technology, applied in the direction of electrolytic components, electrolytic process, etc., to achieve the effect of reducing uneven composition and high magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055]

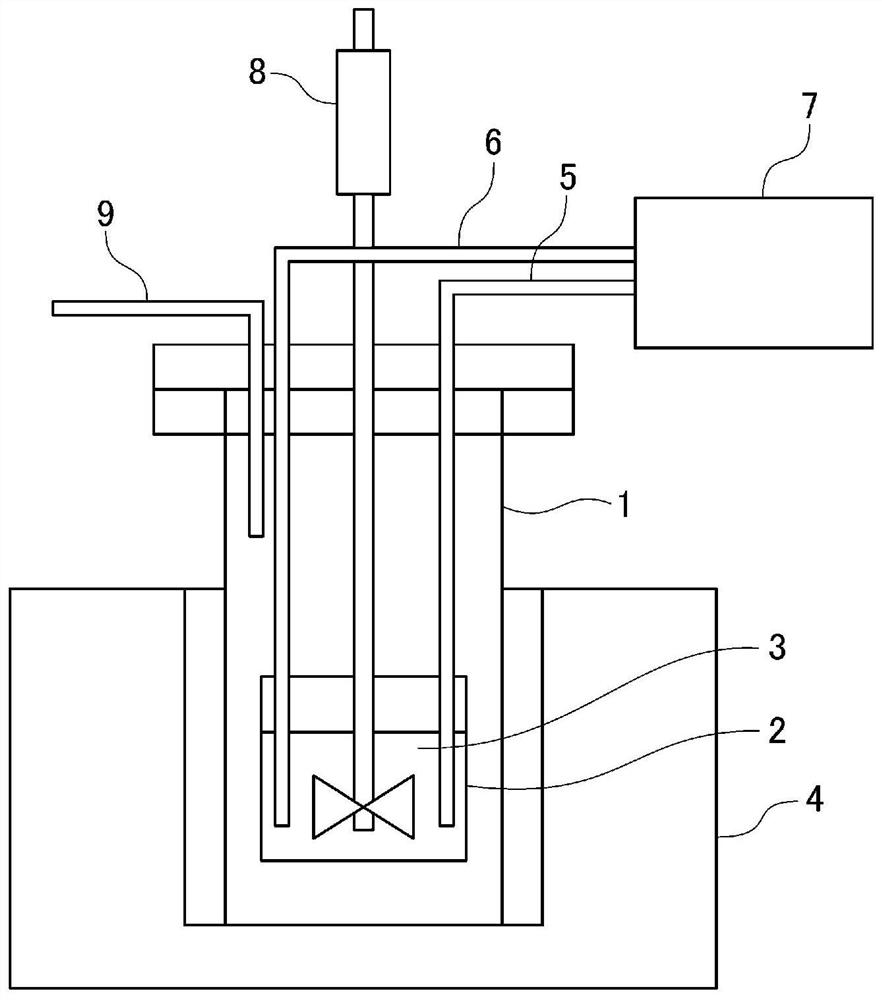

[0056] First, prepare to have figure 1 The electrodeposition setup of the structure shown. The cathode 5 used a Cu plate with a thickness of 3 mm cut so that the area immersed in the molten salt 3 was 5 cm×8 cm, and the anode 6 used an Al plate with a thickness 3 mm cut so that the area immersed in the molten salt 3 was 5 cm×8 cm.

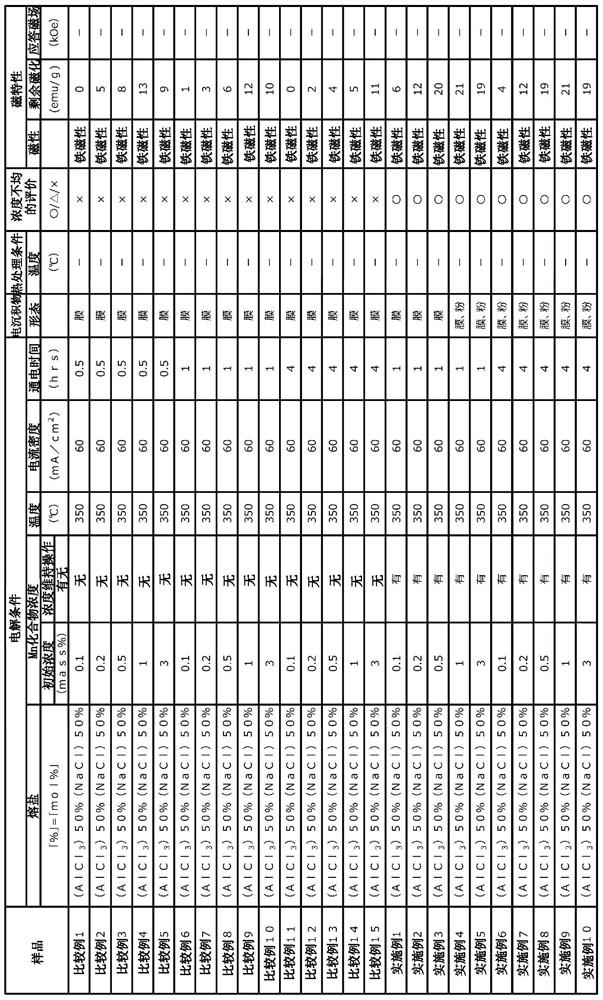

[0057] Next, the anhydrous AlCl as the Al compound 3 and NaCl as other halides were weighed 50mol% respectively, and 0.1mass% of pre-dehydrated MnCl was weighed as a Mn compound 2 , was thrown into the alumina crucible 2 so that the total weight became 1200 g. Therefore, MnCl 2 The amount is 1.2g. Dehydration treatment by MnCl 2 Hydrate in N 2 It is performed by heating at about 400° C. for 4 hours or more in an inert atmosphere such as gas.

[0058] The alumina crucible 2 loaded with the material was moved to the inside of the airtight container 1 , and the material was heated at 350° C. in the electric furnace 4 to obtain the mo...

Embodiment 1~5

[0064] In addition to adding MnCl as a Mn compound in the electrolysis 2 Except that, the samples of Examples 1-5 were produced similarly to Comparative Examples 6-10, respectively.

[0065] MnCl 2 The additional input of is carried out as follows. First, the MnCl 2 Hydrate in N 2 In an inert atmosphere such as gas, dehydration treatment is carried out at about 400°C for more than 4 hours, and the obtained anhydrous MnCl 2 Crush using a mortar under an inert atmosphere. The obtained powder was molded into cylindrical pellets with a diameter of 5 mm to produce anhydrous MnCl 2 particle. The pellets thus obtained are additionally charged into the molten salt 3 during electrolysis. The additional injection of pellets was performed every 10 minutes, and the amount of injection per one time was all 0.38 g in Examples 1-5.

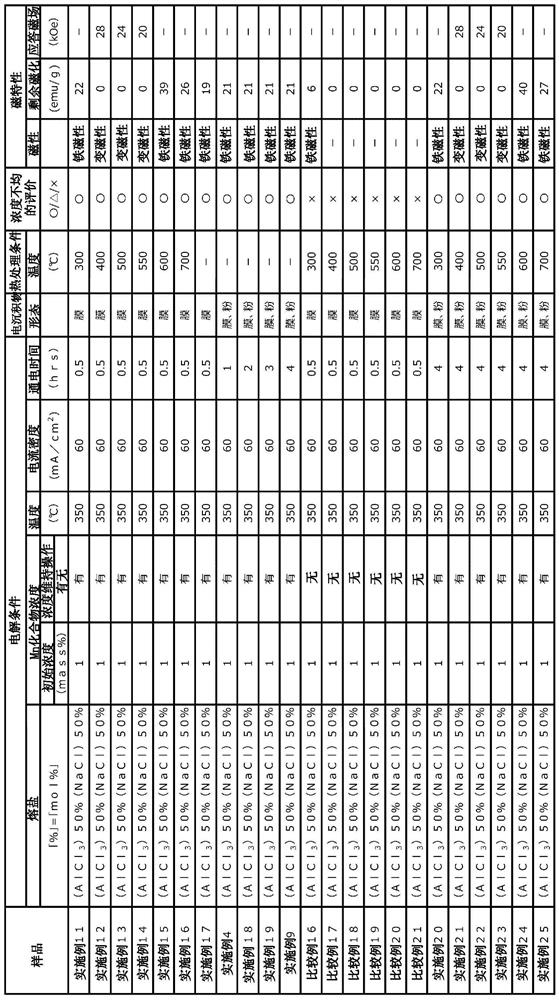

[0066] like figure 2 As shown, the samples of Examples 1 to 5 exhibited ferromagnetism, and had higher remanence magnetization than the corresponding ...

Embodiment 6~10

[0071] In addition to adding MnCl as a Mn compound in the electrolysis 2 Except that, the samples of Examples 6-10 were produced similarly to Comparative Examples 11-15, respectively. The particles used and the feeding conditions were the same as in Examples 1-5, respectively.

[0072] like figure 2 As shown, the samples of Examples 6 to 10 also exhibited ferromagnetism, and their remanence magnetization was larger than those of Comparative Examples 11 to 15, respectively. In addition, in any of Examples 6 to 10, the form of the MnAl alloy precipitated on the cathode 5 was not in the form of a film, but mostly in the form of powder. In addition, in the samples of Examples 6 to 10, the evaluations of density unevenness were all ◯.

[0073] In this manner, in Examples 6 to 10, both the ferromagnetic film-like electrodeposit and the powdery electrodeposit were obtained. The remanent magnetization of the obtained ferromagnetic electrodeposit increases up to an initial concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com