A kind of preparation method of high metallurgical quality tc19 alloy ingot

A technology of TC19 and alloy ingot casting, which is applied in the field of titanium alloy, can solve the problems of difficult smelting process, solidification structure and uniformity of composition, etc., and achieve the effect of increasing the degree of long-distance diffusion and benefiting uniformity

Active Publication Date: 2022-05-31

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For engine materials such as TC19, which has a high degree of alloying and a large difference in the melting point of alloying elements, it is difficult to effectively reduce high melting point inclusions and ensure that the solidification structure and composition uniformity are not reduced by the current smelting process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0053]

[0056]

Embodiment 2

[0065]

[0068]

Embodiment 3

[0077]

[0080]

[0081]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention provides a method for preparing high metallurgical quality TC19 alloy ingots. Aluminum-silicon alloy and sponge zirconium are packaged into alloy package A, aluminum-molybdenum alloy and titanium-tin alloy are packaged into alloy package B, and pure aluminum, titanium dioxide and iron powder Wrap into alloy package C, arrange in the order of alloy package A on the top, alloy package B on the middle, and alloy package C on the bottom, and press the TC19 titanium alloy with the cloth method covered and filled by sponge titanium between the upper and lower outermost layers and the alloy package The electrodes are dried and welded with a plasma torch; the vacuum consumable arc melting process is used to melt the primary ingot, the plasma cooling bed furnace melting process is used to melt the secondary ingot, and the vacuum consumable arc melting process is used to melt the third ingot. In the present invention, the electrode is pressed by a special material distribution method to improve the rationality of the distribution of alloy elements in the electrode, and the combination of the two smelting methods further ensures the uniform distribution of each element in the ingot, and reduces high-density inclusions, pores and Metallurgical defects such as cold shut.

Description

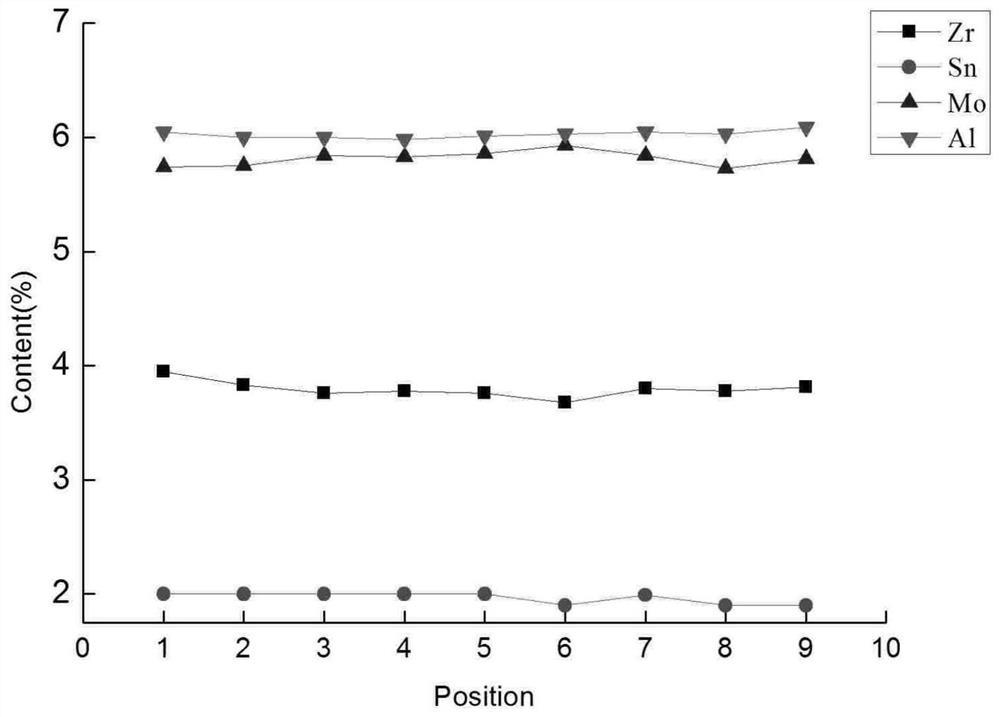

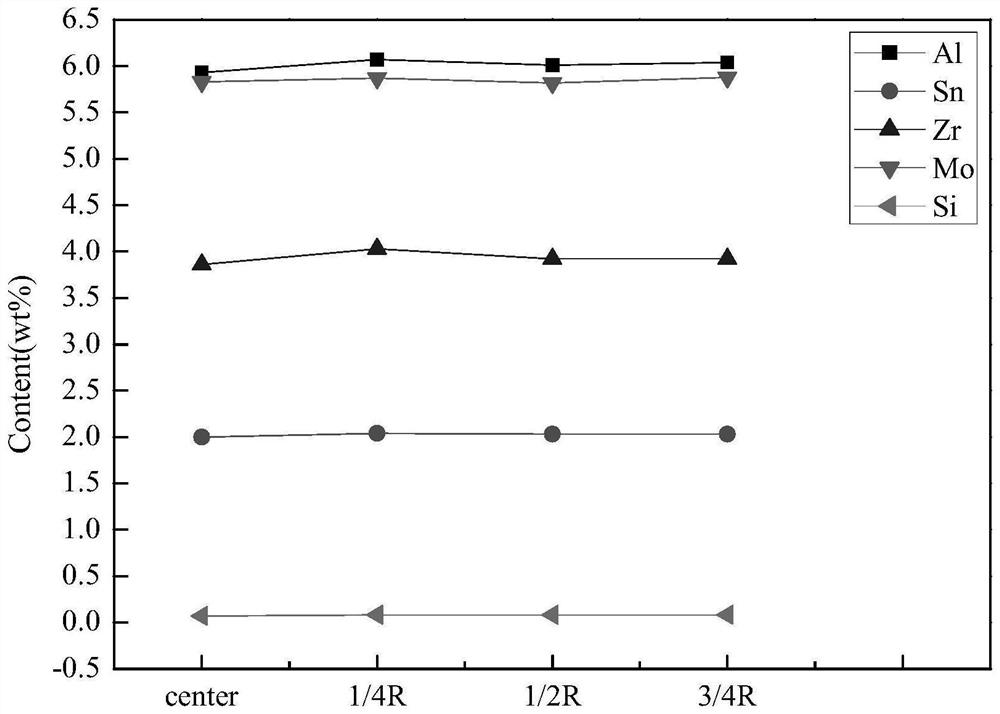

A kind of preparation method of high metallurgical quality TC19 alloy ingot technical field The invention belongs to titanium alloy technical field, be specifically related to a kind of preparation method of high metallurgical quality TC19 alloy ingot Law. Background technique TC19 titanium alloy nominal composition is Ti-6Al-2Sn-4Zr-6Mo (mass percent, wt.%), belongs to martensite α+ Beta-type heat-strength titanium alloy. The alloy is mainly used for parts in the mid-temperature section of turbine engines such as compressor discs, fans and blades. The long-term use temperature is around 400 °C, and the short-term temperature can reach 540 °C. The main alloying elements of TC19 are Al, Sn, Zr, Mo four kind. Compared with Ti element, Al and Sn elements have lower melting point and lower density, and the saturated vapor pressure at the same temperature is much greater than that of Ti. The saturated vapor pressure is a volatile alloy element; the melting point and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C1/03B22D7/00C22B9/20C22B9/22

CPCC22C1/03C22B9/226C22B9/20B22D7/005Y02P10/20

Inventor 朱绍祥王清江刘建荣王磊陈志勇李文渊赵子博

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com