Anti-bacterial pressure-resistant vacuum dropper combination bottle and material preparation method thereof

A technology of vacuum bottles and dropper bottles, which is applied to the types of packaging items, applications, special packaging items, etc., can solve the problems that dropper bottles and vacuum bottles are difficult to combine and use independently, and achieve a feasible preparation method, simple combination and simple use. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

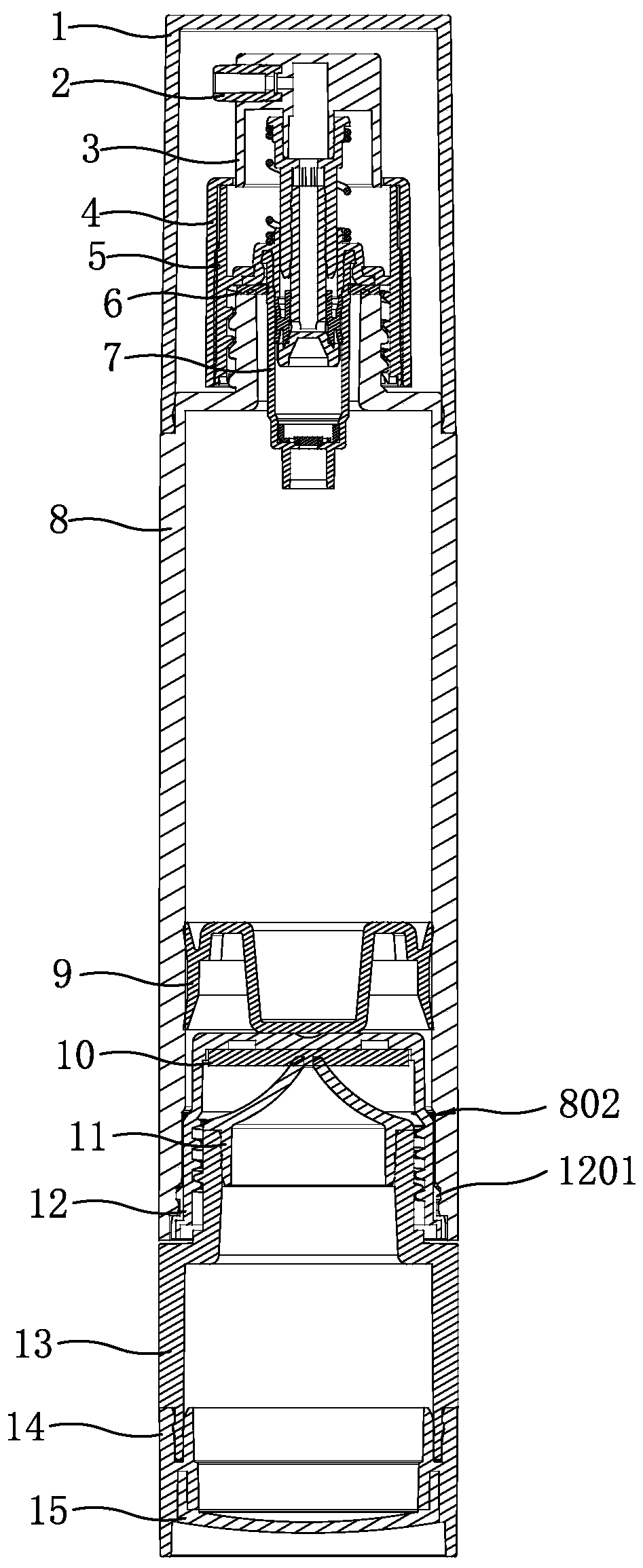

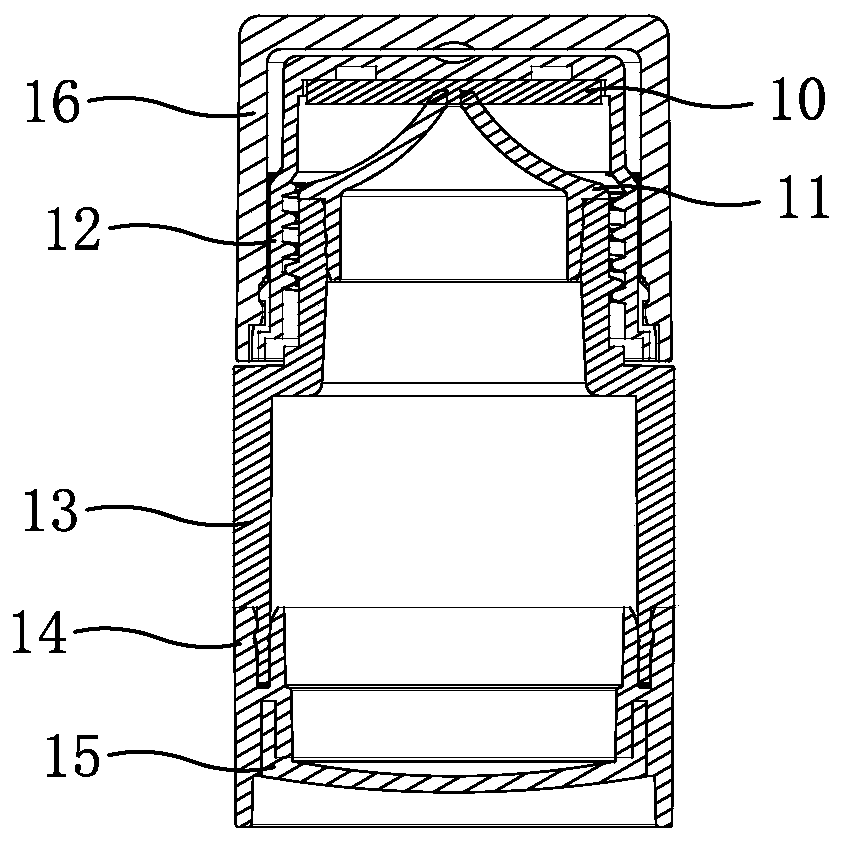

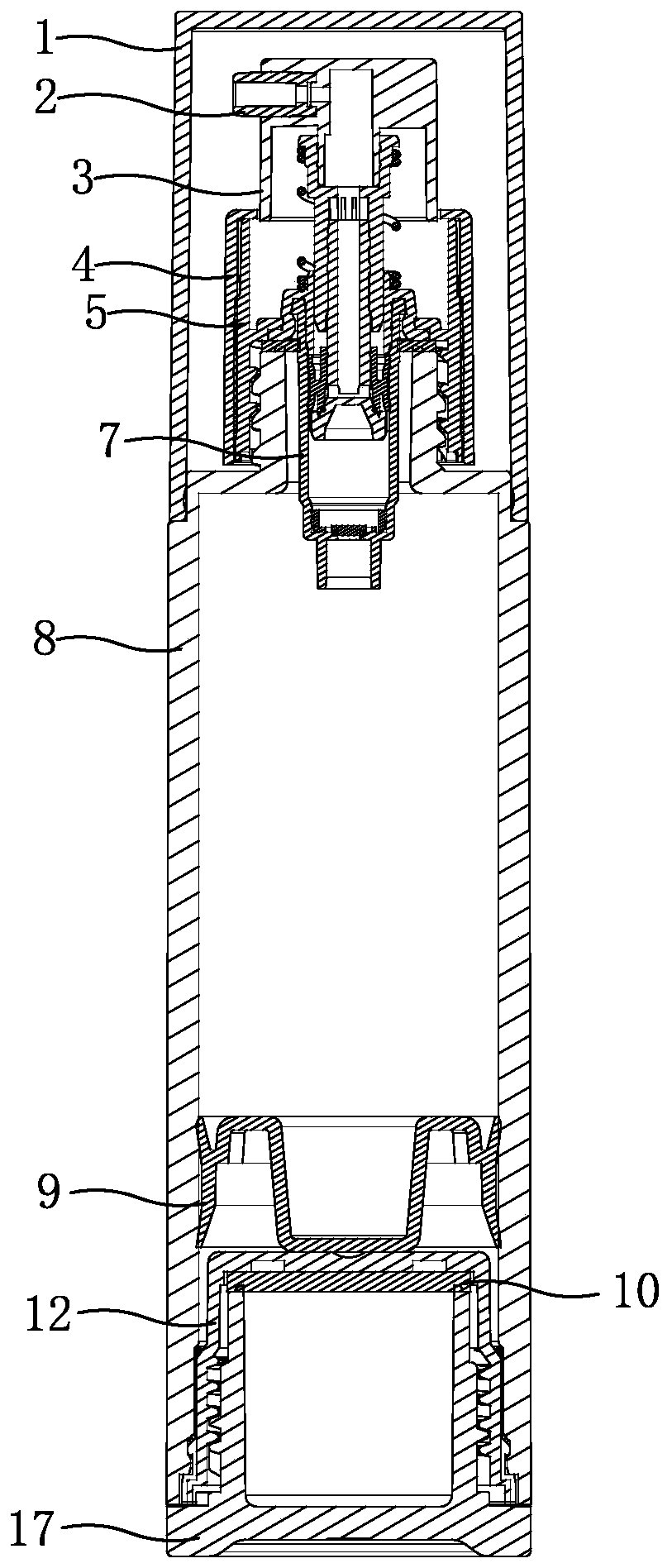

[0023] Now in conjunction with the accompanying drawings, the structure of the present invention will be further described. like Figure 1-Figure 9 As shown, one end of the combination bottle is a vacuum bottle, and the other end is a dropper bottle. A large piston 9 is arranged in the vacuum bottle body 8 of the vacuum bottle body. The inner wall of the vacuum bottle above the mouth is provided with a buckle groove 801, and the inner wall of the vacuum bottle above the buckle ring is provided with vertical grooves 802 distributed evenly and equidistantly, and the vertical groove is arranged on the raised ring rib of the inner wall of the vacuum bottle; The outer diameter of the inner cover 12 of the tube bottle is provided with a raised cover ring, and the outer wall of the dropper bottle above the cover ring is provided with buckle ribs 1201, and the outer wall of the inner cover above the buckle ribs is provided with uniformly equidistant distribution and convex rings. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com