Magnetic particle grinding device and method for efficient polishing of inner surface of pipe

A technology of grinding device and inner surface, applied in surface polishing machine tools, grinding drive devices, machine tools suitable for grinding workpiece edges, etc. Achieve the effect of improving the grinding process track, uniform and sufficient grinding and polishing, and improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

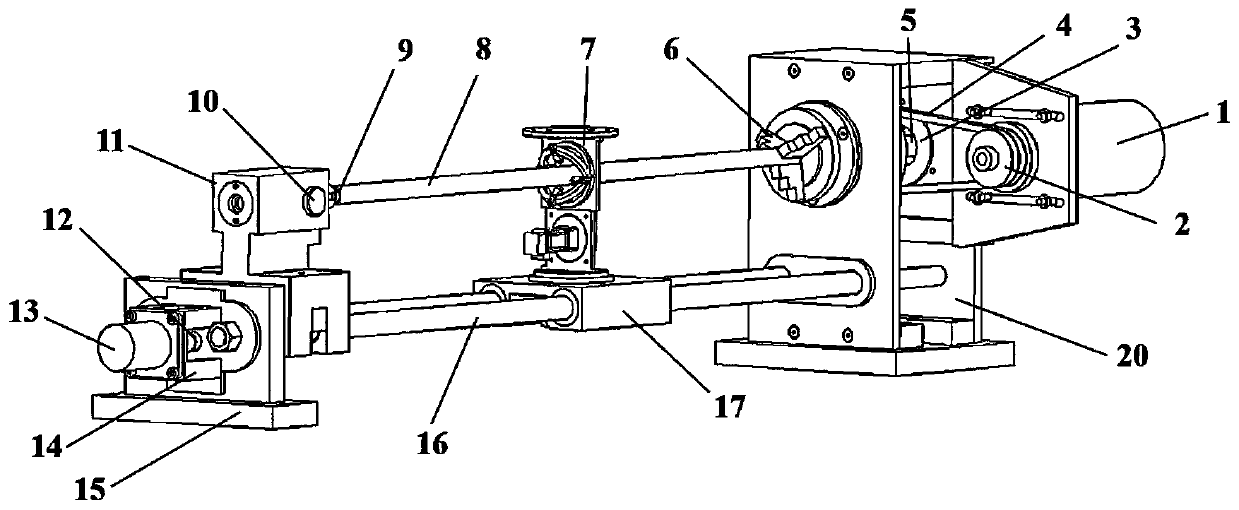

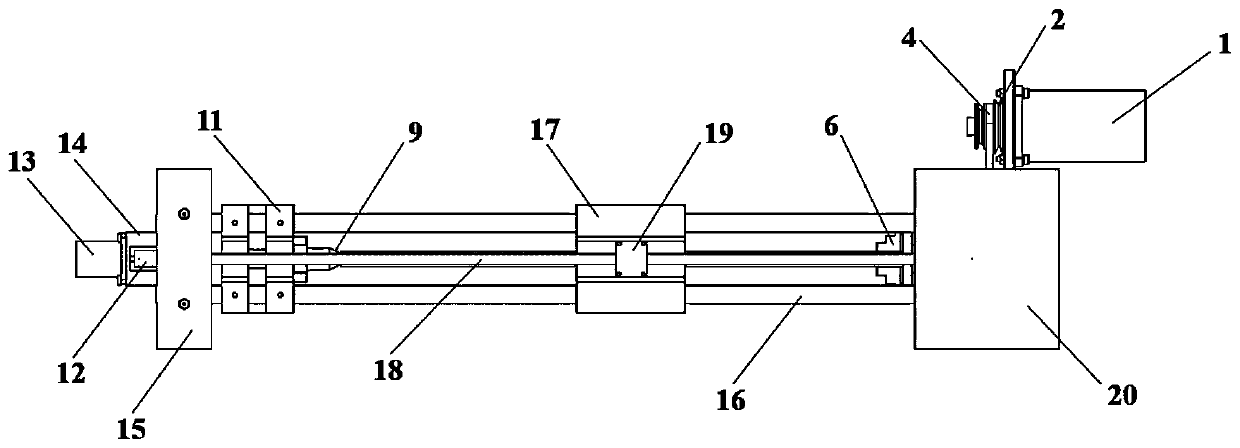

[0033] See figure 1 , figure 2 , a magnetic particle grinding device for efficiently polishing the inner surface of a tube, comprising a driving mechanism, a feeding mechanism, and a magnetic field generating mechanism 7, the driving mechanism drives the tubular part 8 to rotate, and the feeding mechanism drives the magnetic field generating mechanism 7 along the tubular part 8 Axial movement; the magnetic field generating mechanism 7 forms a magnetic field, absorbs the magnetic abrasive particles 35 and arranges them along the magnetic field lines, and gathers them into rigid magnetic particle brushes.

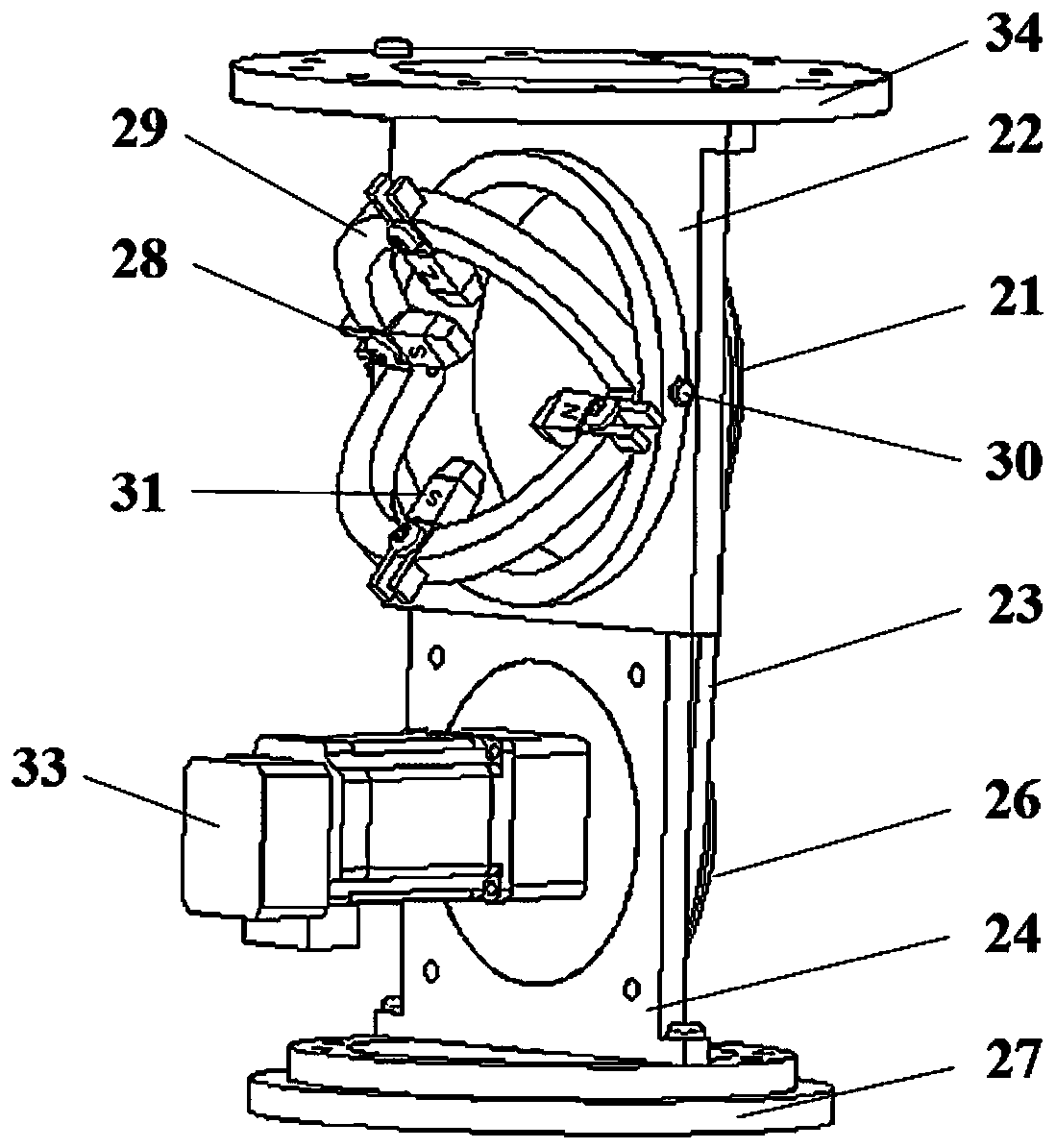

[0034] See image 3 , Figure 4 , Figure 7 , the magnetic field generating mechanism 7 includes flange one 34, flange two 27, large pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com