Automatic CASS reaction tank sludge age control system

An automatic control system and reaction pool technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficulty in determining the timing of sludge discharge, excessive COD of effluent, and poor control of sludge age Accuracy and other issues, to achieve the effect of accurate calculation and stable mud volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

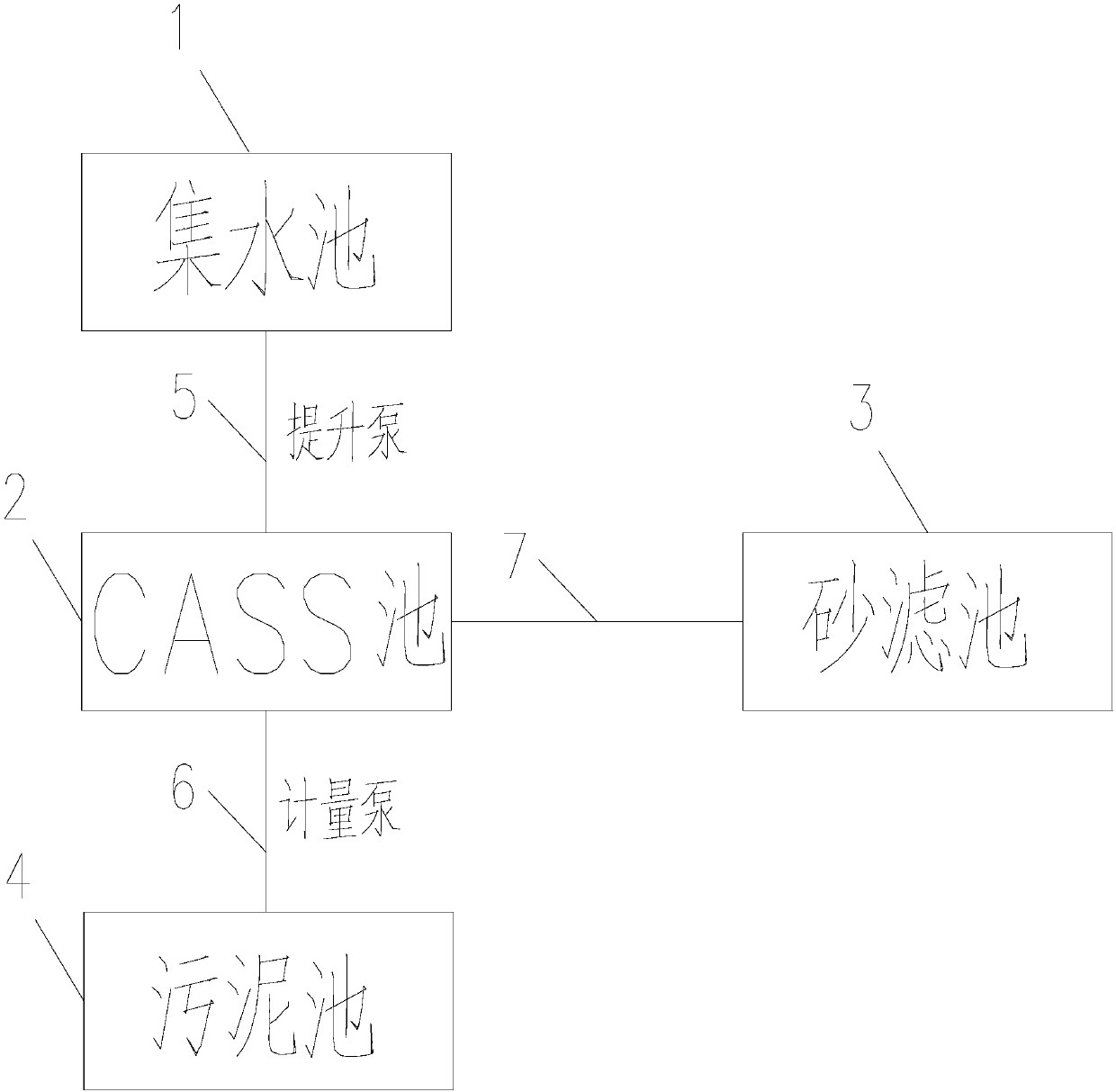

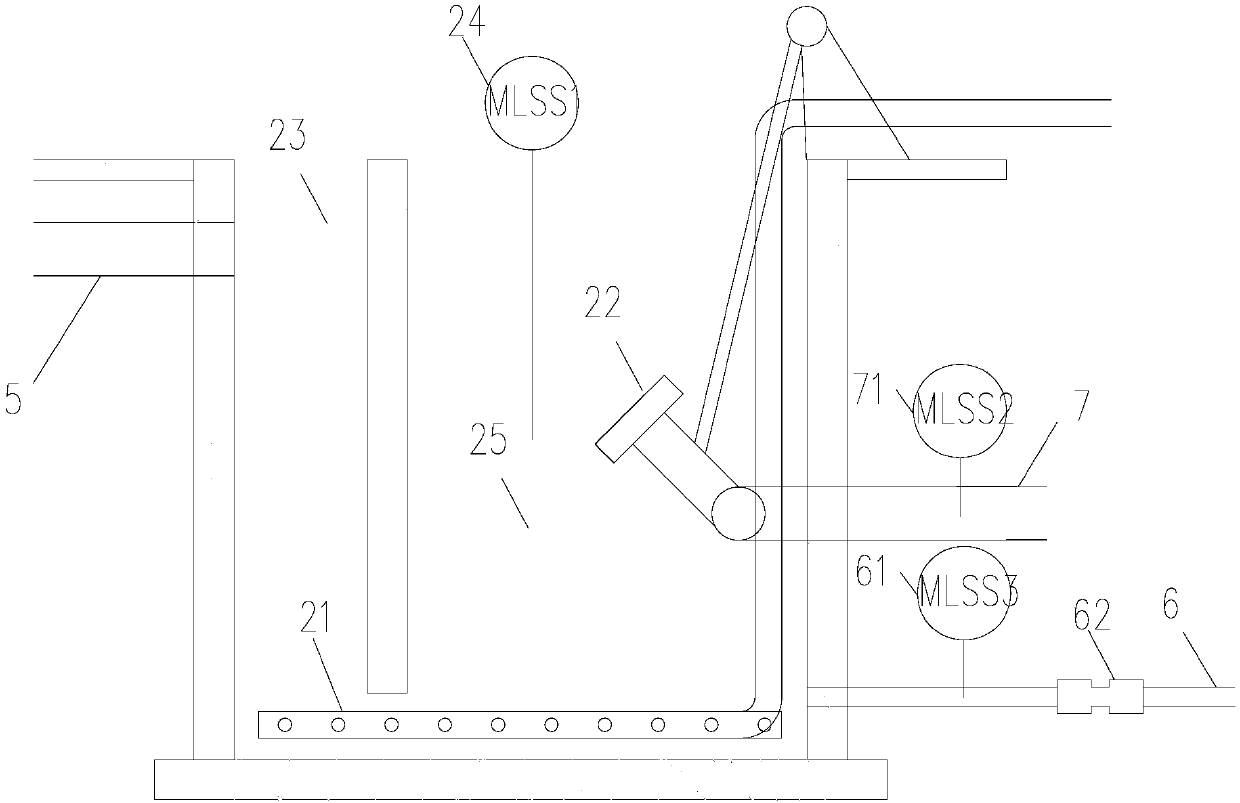

[0041] Such as figure 1 with figure 2 , combined with the conclusion of the above theoretical demonstration, the implementation steps of the present invention will be described in detail through a case below. In order to simplify the entire elaboration process, the measurement units of each indicator in the case have been converted.

[0042] Case, CASS Reaction Pool T S Set to 26 days, the aerobic stage MLSS1 in the reaction pool is controlled at 4-5kg / m 3 , the effective volume V of the reaction pool is 100m 3 , the water output rate of the reaction pool is 35%, and the MLSS2 value in the water output index of the reaction pool is 0.08kg / m 3 Below, the flow Q of the sludge metering pump v 5m 3 / h, the measured value of MLSS3 of the discharged sludge concentration is 15-25kg / m 3 , the dissolved oxygen DO in the pretreatment section of the reaction pool is below 0.5, and the DO in the aerobic section is 2-4. The conventional process control is to discharge mud once a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com