Guiding and damping device for open hole well measuring instrument

A technology of well logging instruments and shock absorbing devices, which is applied in the direction of wellbore/well components, measurement, construction, etc., and can solve problems such as low logging efficiency, damage, and instrument failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

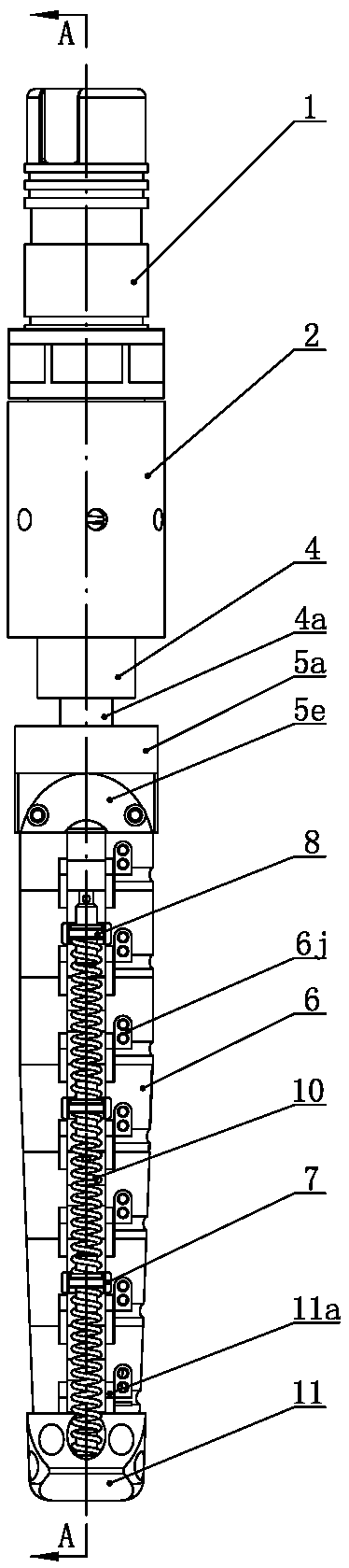

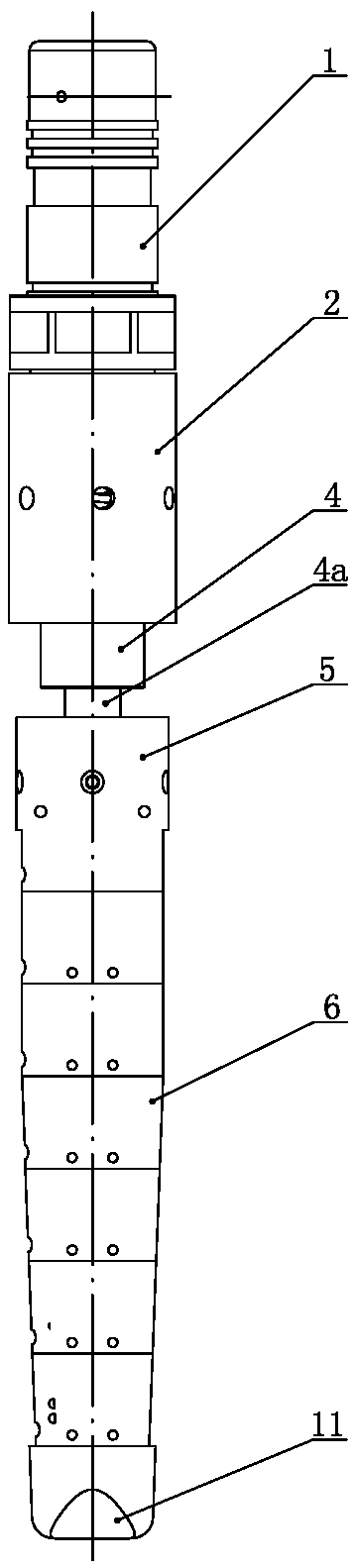

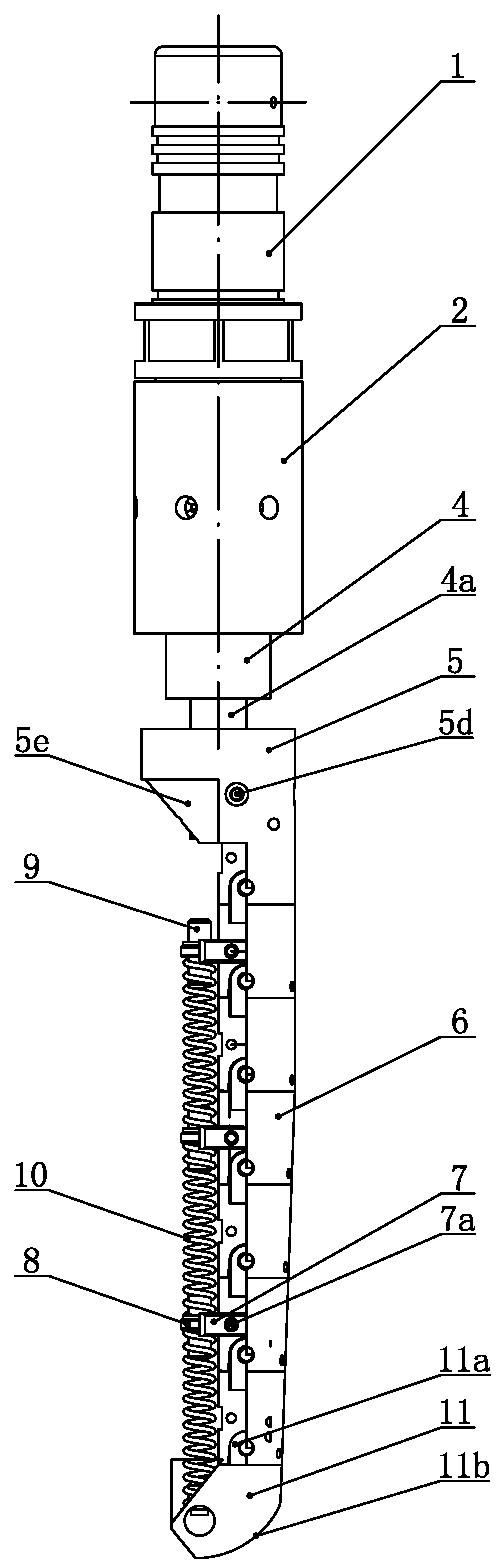

[0032] Figure 1 to Figure 10 Shown is the first embodiment of the present invention. The guiding and damping device for the open-hole logging instrument includes an upper joint 1 connected to the logging instrument, and a soft whip connection device is suspended below the upper joint 1. The lower end of the soft whip connecting device is connected with a soft whip assembly extending downward, and the lower end of the soft whip assembly is connected with a guide head 11; the soft whip assembly includes a plurality of sequentially hinged soft whip blocks 6, and each soft whip block 6 The side facing the well wall is a soft whip block arc surface 6a, and the side of each soft whip block 6 facing the center of the borehole is a soft whip block plane 6b, and the upper ends of each soft whip block 6 are respectively provided with a soft whip block protruding upward. The hinge joint 6c of the whip block; the lower part of each soft whip block plane 6b is respectively provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com