Flat-bottom vertical dual-wall liquefied natural gas storage tank

A liquefied natural gas, vertical technology, used in fixed-capacity gas storage tanks, gas processing/storage purposes, gas/liquid distribution and storage, etc., to achieve high measurement accuracy, improve pressure accuracy, and reduce numerical fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

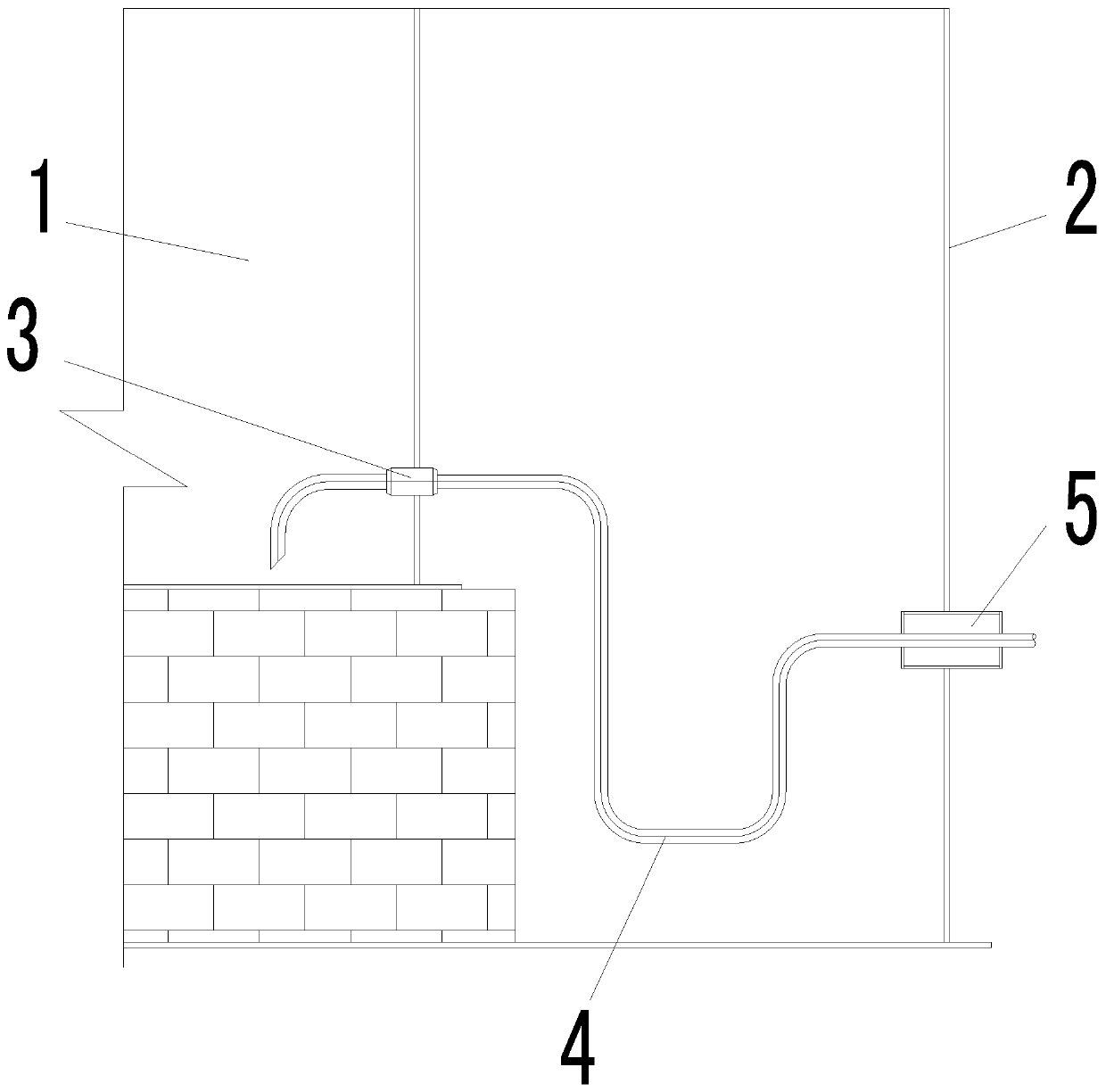

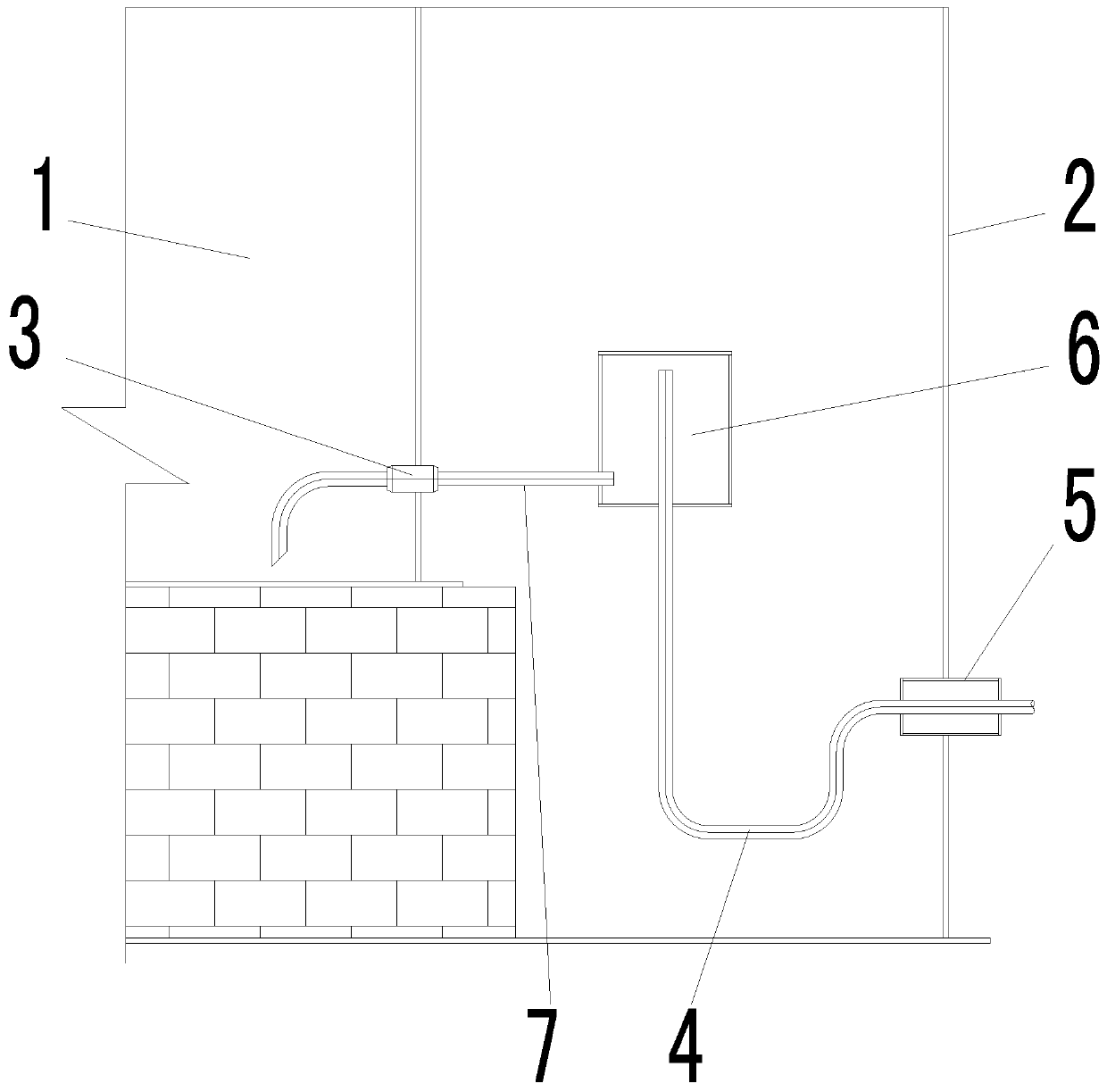

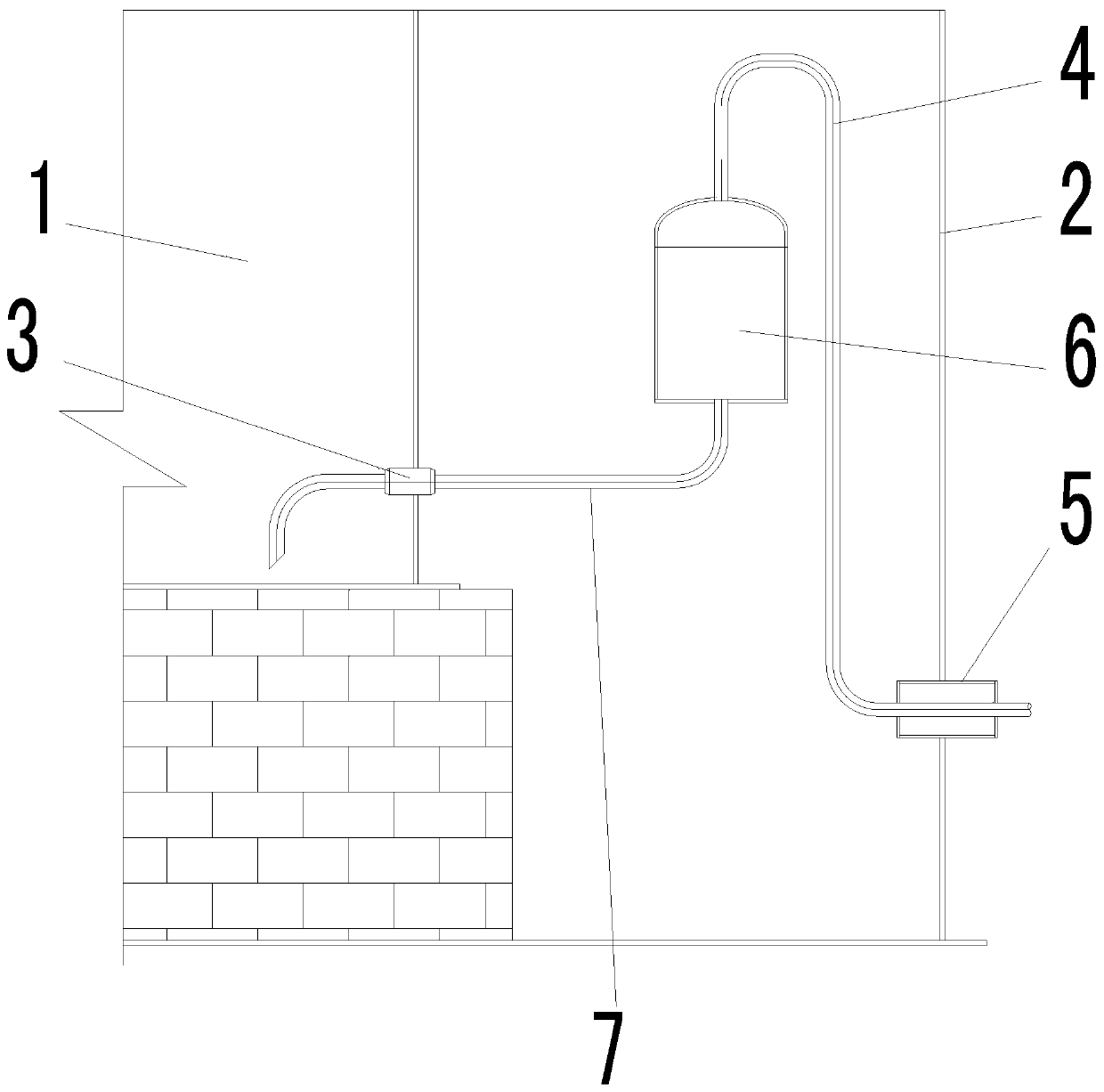

[0022] attached figure 2 It is the first embodiment of the flat bottom vertical double-wall liquefied natural gas storage tank according to the present invention, which includes an inner tank 1, a first pressure taking pipe 7 and a second pressure taking pipe 4; the outside of the inner tank 1 is provided with an outer Tank 2; the outer tank 2 wraps the inner tank 1; the gap between the outer tank 2 and the inner tank 1 is filled with a thermal insulation layer (not shown); one end of the first pressure-taking pipe 7 is set by The transition pipe 3 on the side wall of the inner tank 1 enters the interior of the inner tank 1, and the other end enters the buffer tank 6 arranged in the outer tank 2; one end of the second pressure-taking pipe 4 is inserted from the bottom of the buffer tank 6 Inside the buffer tank 6, the other end is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com