Infrared waveband SPR refractive index sensor

A technology of refractive index sensor and infrared band, which is applied in the field of infrared band refractive index sensor, can solve problems such as difficulty in making high-sensitivity sensors, and achieve the effect of expanding the range of GH displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

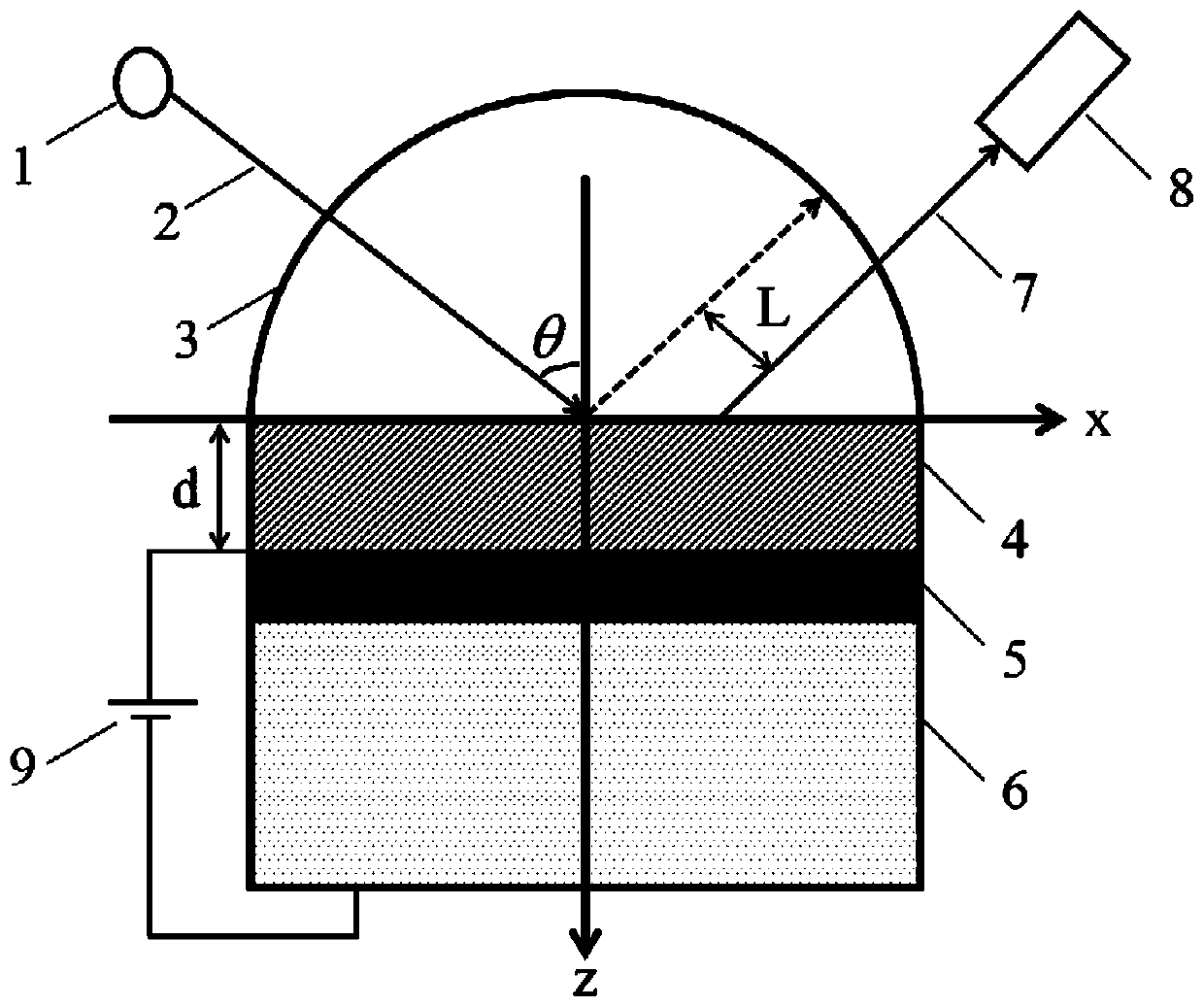

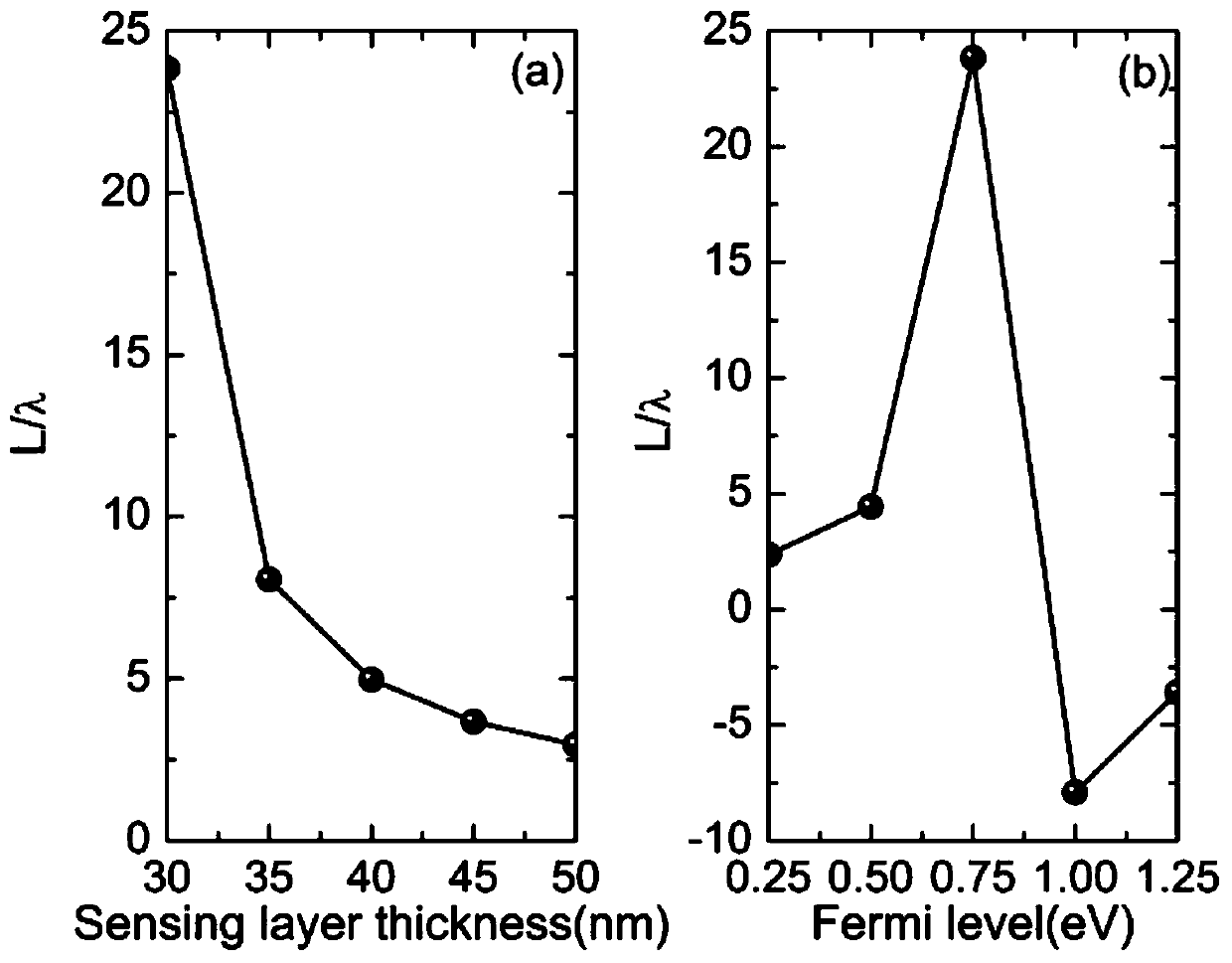

[0026] Embodiment 1: The high refractive index prism of the sensor is a semi-cylindrical glass prism, and the material of the prism is BK7 glass. The thickness of the sensing medium layer is 30nm-50nm, and the refractive index is 1.000RIU. The thickness of the graphene layer is 0.34nm, and the thickness of the hexagonal boron nitride is 3mm. The incident beam is transverse magnetically polarized light, and the working wavelength is 13.14 μm. The working Fermi level is 0.75eV. Depend on figure 2 (a) It can be seen that when the thickness of the sensing layer is changed, it can be found that the GH shift value L is the largest when the thickness of the sensing layer is 30 nm. Therefore, in order to enhance the GH shift and make the phenomenon more obvious, we choose a sensing medium layer thickness of 30nm for this sensor. figure 2 The high-index prism of the sensor in (b) is a semi-cylindrical glass prism. The thickness of the sensing medium layer is 30nm, and the refrac...

Embodiment 2

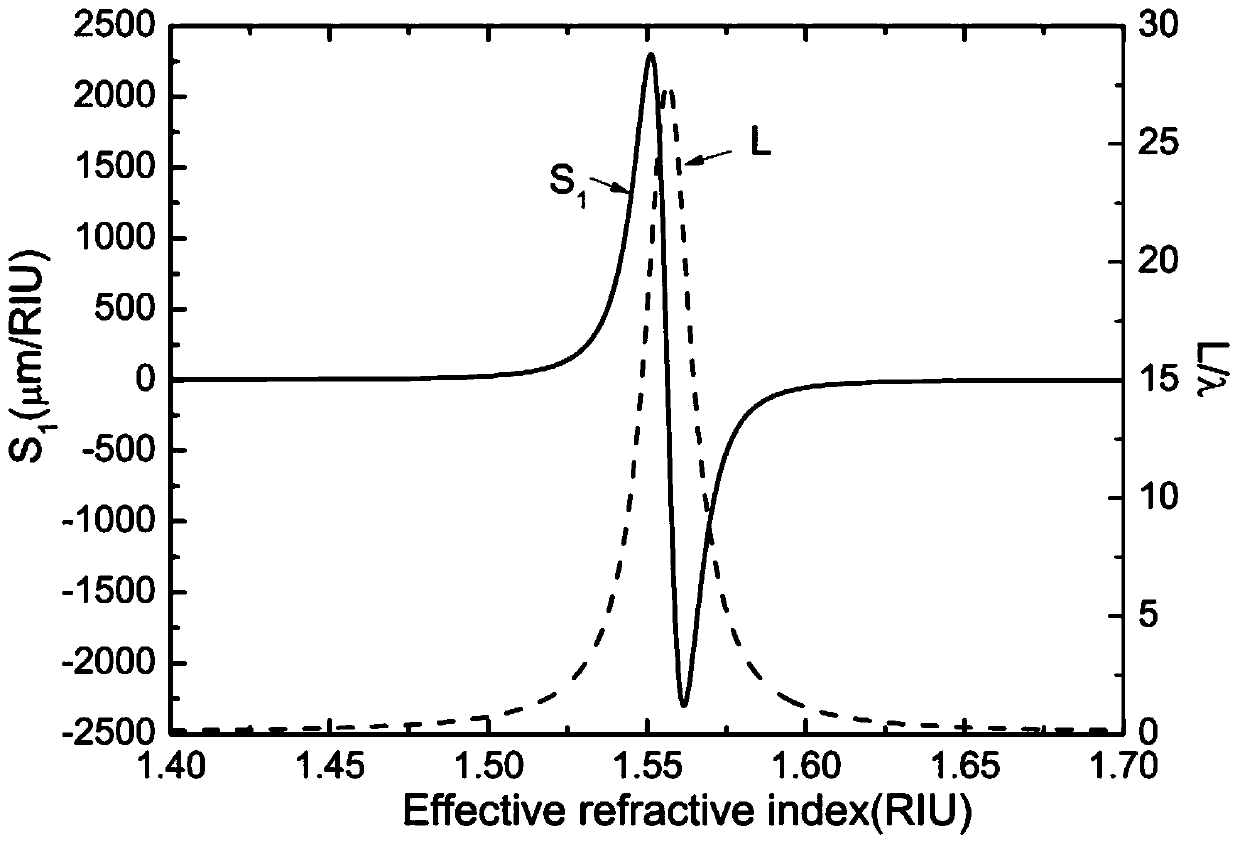

[0027] Embodiment 2: The high refractive index prism of the sensor is a semi-cylindrical glass prism, and the material of the prism is BK7 glass. The thickness of the sensing medium layer is 30nm, and the refractive index is 1.000RIU. The thickness of the single-layer graphene layer is 0.34nm, and the thickness of the hexagonal boron nitride is 3mm. The incident beam is transverse magnetically polarized light, and the working wavelength is 13.14 μm. The working Fermi level is 0.75eV. Depend on image 3 It can be seen that high sensitivity is obtained when the resonance angle is close to the resonance peak. Therefore, we choose an incident angle with high sensitivity and large GH shift. At this time, the effective refractive index was 1.5513RIU, and the incident angle was 45.08°. Incident at this angle, the sensor is more sensitive.

Embodiment 3

[0028] Embodiment 3: The high refractive index prism of the sensor is a semi-cylindrical glass prism, and the material of the prism is BK7 glass. The thickness of the sensing medium layer is 30nm, and the refractive index is 1.000 / 1.003RIU. The thickness of the graphene layer is 0.34nm, and the thickness of the hexagonal boron nitride is 3mm. The incident beam is transversely magnetically polarized. The working Fermi level is 0.75eV. Depend on Figure 4 It can be seen that when the wavelength of the incident light changes, the GH shift of the reflected light also changes, resulting in a peak. Under a fixed angle of incidence, the working wavelength is selected at the middle position of the falling edge of the resonance peak, that is, 13.128 μm. Here the sensor can get good linearity and sensitivity. When the refractive index of the sensing medium changes from 1.000RIU to 1.003RIU, the GH displacement changes by 8*λ. Calculated by the formula, the sensitivity of the sensor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com