Indoor formaldehyde degradation device

A technology for formaldehyde degradation and formaldehyde, applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of troublesome degradation of formaldehyde, large consumption of chemicals, and low amount of formaldehyde dissolved, so as to improve the absorption capacity and increase the use of The effect of aging and increasing the degree of beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

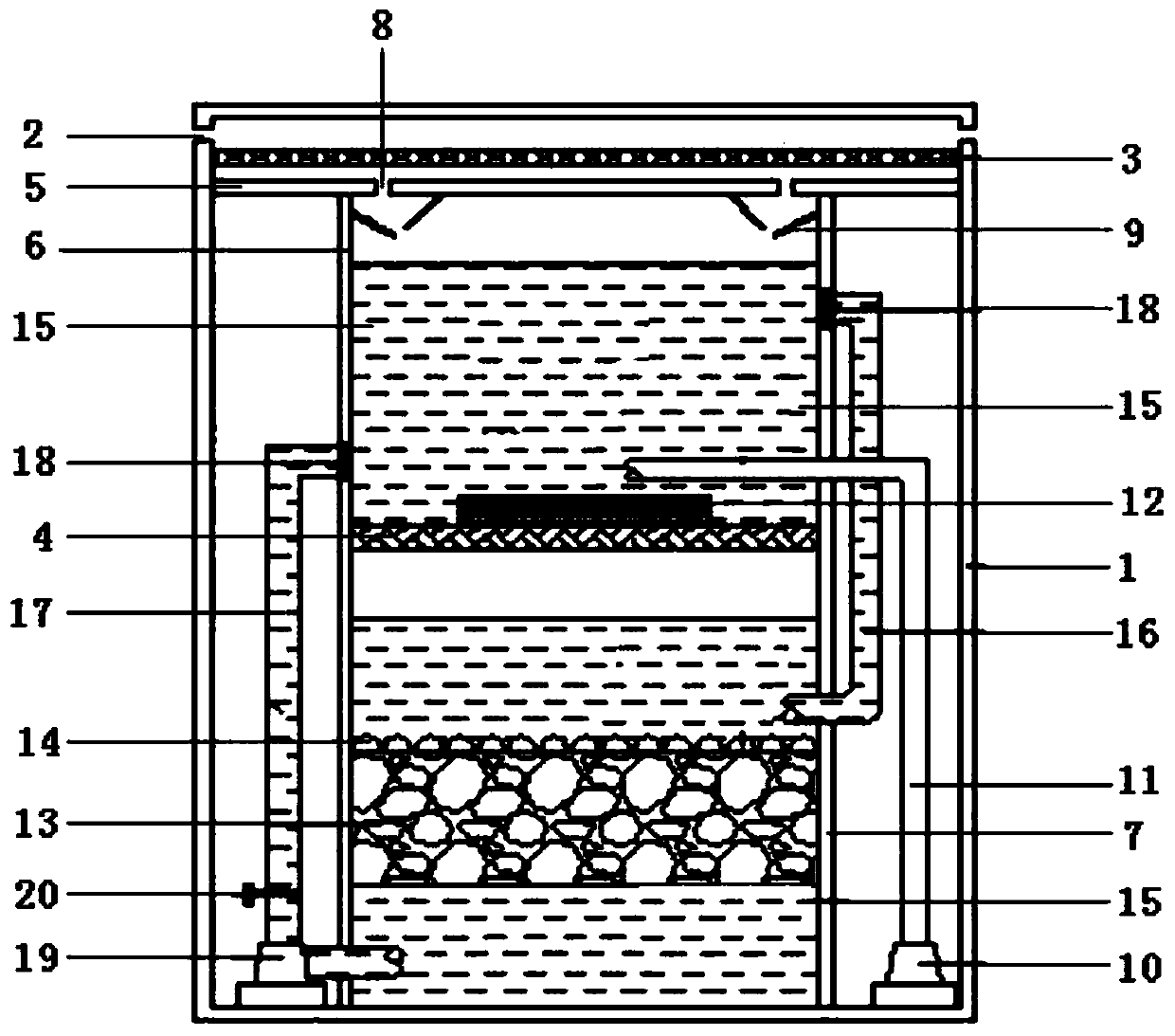

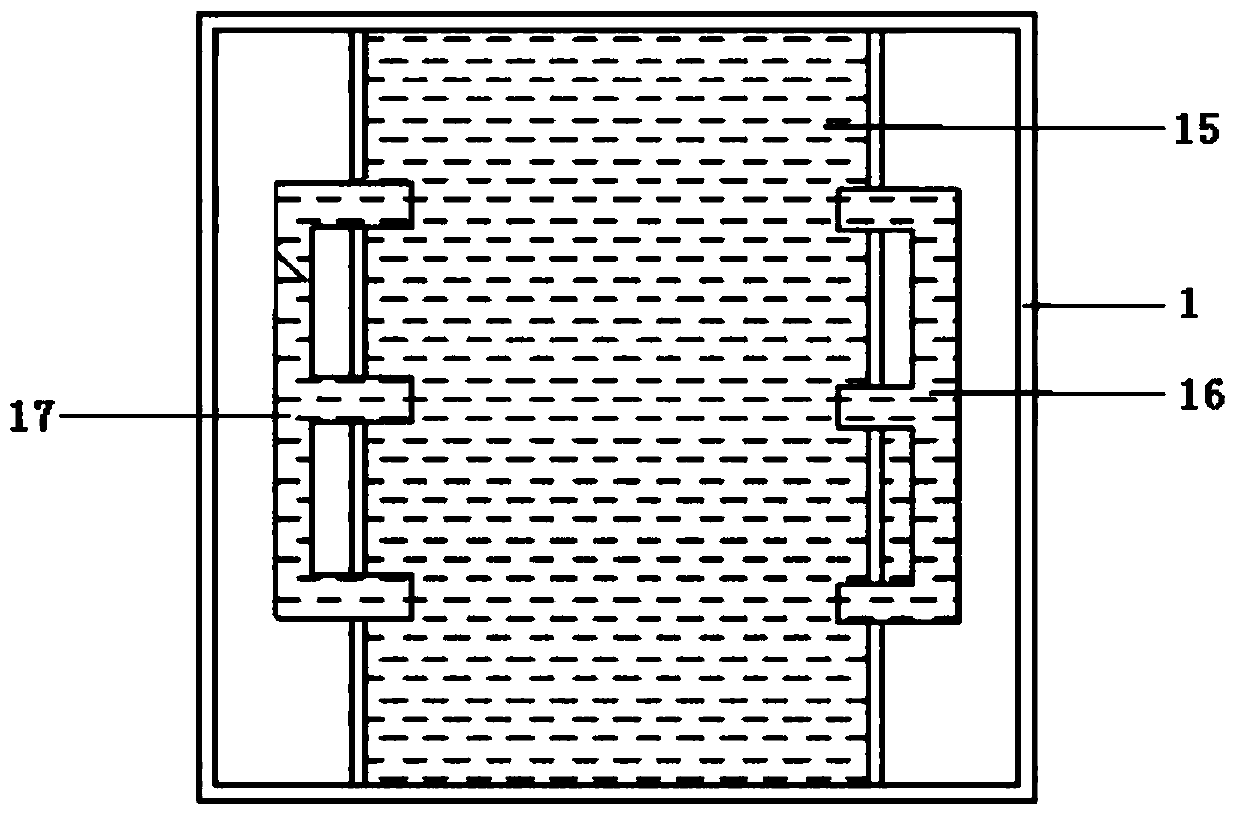

[0020] The main structure of the indoor formaldehyde degradation device involved in this embodiment includes a reaction vessel 1, a first vent 2, an activated carbon carrier 3, a partition 4, a cover 5, an upper chamber 6, a lower chamber 7, and a second vent 8 , baffle plate 9, air pump 10, ventilation pipeline 11, ultrasonic generator 12, microbial carrier 13, biofilm 14, liquid culture medium 15, upper communication pipeline 16, lower communication pipeline 17, screen 18, water pump 19 and check valve 20; The top side wall of the reaction vessel 1 with an inner hollow structure is provided with first vents 2 arranged in pairs, and an activated carbon carrier 3 is arranged below the first vents 2 in the reaction vessel 1, and the activated carbon carrier 3 in the reaction vessel 1 The bottom of the upper chamber is divided into an upper chamber 6 and a lower chamber 7 by a partition plate 4 and a cover plate 5, the cover plate 5 is fixedly connected with the reaction vessel 1...

Embodiment 2

[0023] When the indoor formaldehyde degradation device involved in this embodiment is in use, the air pump 10 draws the indoor air containing formaldehyde into the upper chamber 6 through the vent pipe 11, and the ultrasonic generator 12 works intermittently to shatter the water molecules in the upper chamber 6, Formaldehyde and water molecule contact and fuse in a large area, so that the liquid culture medium 15 in the upper chamber 6 contains sufficient formaldehyde, and at the same time, the liquid culture medium 15 in the upper chamber 6 flows into the lower chamber 7 through the upper communication pipe 16, so that Formaldehyde enters the lower chamber 7. The formaldehyde stays on the microbial carrier 13 and the biofilm 14 and is degraded. The degraded gas is transported to the upper chamber 6 through the water pump 19 and the communication pipe 17, and passes through the second vent 8 and the activated carbon carrier in turn. 3 and the first vent 2 enter the room, wherei...

Embodiment 3

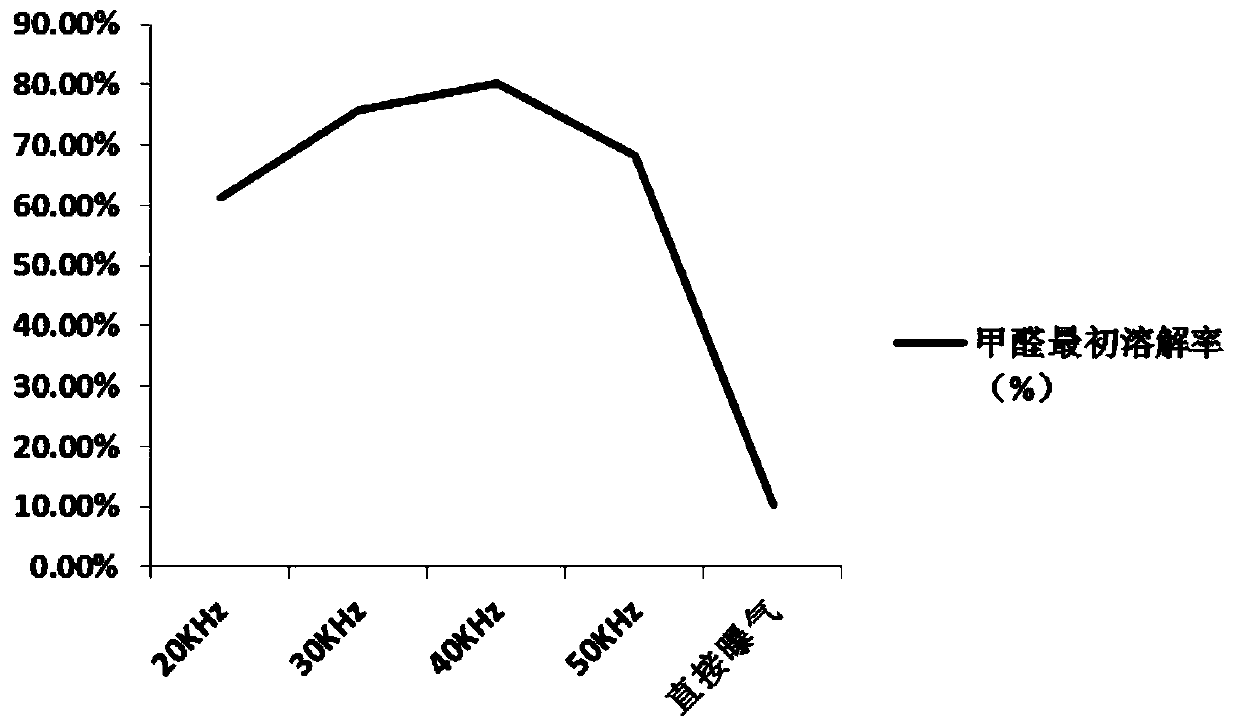

[0025] The indoor formaldehyde degradation device involved in this embodiment adopts ultrasonic generator 12 aeration and the formaldehyde degradation device in the prior art adopts direct aeration to dissolve the formaldehyde that concentration is 3.0mg / L respectively, utilizes the formaldehyde that high performance liquid chromatography measures to dissolve rate as image 3 Shown, the formaldehyde dissolution rate of ultrasonic generator 12 aeration is higher than the formaldehyde dissolution rate of direct aeration; When the frequency of ultrasonic generator 12 is 40KHz, the formaldehyde dissolution rate is maximum; Ultrasonic generator 12 has deactivation effect to formaldehyde-reducing bacteria , the calculation formula of the sample microbial inactivation rate (i) under different ultrasonic conditions is: i=(1-Nt / N0) × 100%, wherein, Nt is the number of microbial colonies in the water sample after ultrasonic treatment, cfu / mL; N0 is the number of microbial colonies in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com