Catalyst for hydrogenation liquefaction of biomass, preparation method and method for hydrogenation of biomass

A hydrogenation catalyst and biomass technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and the preparation of liquid hydrocarbon mixtures. It can solve the problems of poor catalytic effect and easy spontaneous combustion during the grinding process, and shorten the equipment. , reduce production cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for biomass hydrogenation liquefaction catalyst, comprising the steps of:

[0031] (1) Add a desulfurizer with a particle size of 80 mesh and water into the reactor to obtain an iron-based desulfurizer slurry with a solid content of 1% by weight; the activity of the desulfurizer is divided into α-type Fe 2 o 3 , the content of iron element is 10wt% of the mass of desulfurizer;

[0032] (2) Inject H into the iron-based desulfurizer slurry 2 The volume concentration of S is 4% nitrogen, the temperature in the reactor is maintained at 10°C, the pressure is normal pressure, and the H contained in the gas at the outlet of the reactor is 2 The concentration of S and the H contained in the gas at the inlet 2 The concentration of S is equal, that is, the iron-based desulfurizer slurry reaches desulfurization saturation, and the introduction of H-containing 2 S nitrogen;

[0033] (3) Solid-liquid separation and vacuum drying at a temperature of 70° C. to obtain Cat...

Embodiment 2

[0035] A method for biomass hydrogenation liquefaction catalyst, comprising the steps of:

[0036] (1) Add a desulfurizer with a particle size of 90 mesh and water into the reactor to obtain an iron-based desulfurizer slurry with a solid content of 50%; the activity of the desulfurizer is divided into γ-type Fe 2 o 3 , the content of iron element is 70wt% of the mass of desulfurizer;

[0037] (2) At a gas flow rate of 0.2L / min, feed H2 into the iron-based desulfurizer slurry 2 The volume concentration of S is 0.01% methane, the temperature in the reactor is maintained at 95°C, the pressure is normal pressure, and the H contained in the gas at the outlet of the reactor is 2 The concentration of S and the H contained in the gas at the inlet 2 The concentration of S is equal, that is, the iron-based desulfurizer slurry reaches desulfurization saturation, and the introduction of H-containing 2 methane of S;

[0038] (3) Solid-liquid separation and vacuum drying at a temperatu...

Embodiment 3

[0040] A method for biomass hydrogenation liquefaction catalyst, comprising the steps of:

[0041] (1) Add a desulfurizer with a particle size of 120 mesh and water into the reaction vessel to obtain an iron-based desulfurizer slurry with a solid content of 36%; The content is 20wt% of the mass of the desulfurizer;

[0042] (2) At a gas flow rate of 1L / min, inject H into the iron-based desulfurizer slurry 2 The volume concentration of S is 2.5% nitrogen, the temperature in the reactor is kept at 90°C, the pressure is normal pressure, and the H contained in the gas at the outlet of the reactor is 2 The concentration of S and the H contained in the gas at the inlet 2 The concentration of S is equal, that is, the iron-based desulfurizer slurry reaches desulfurization saturation, and the introduction of H-containing 2 S nitrogen;

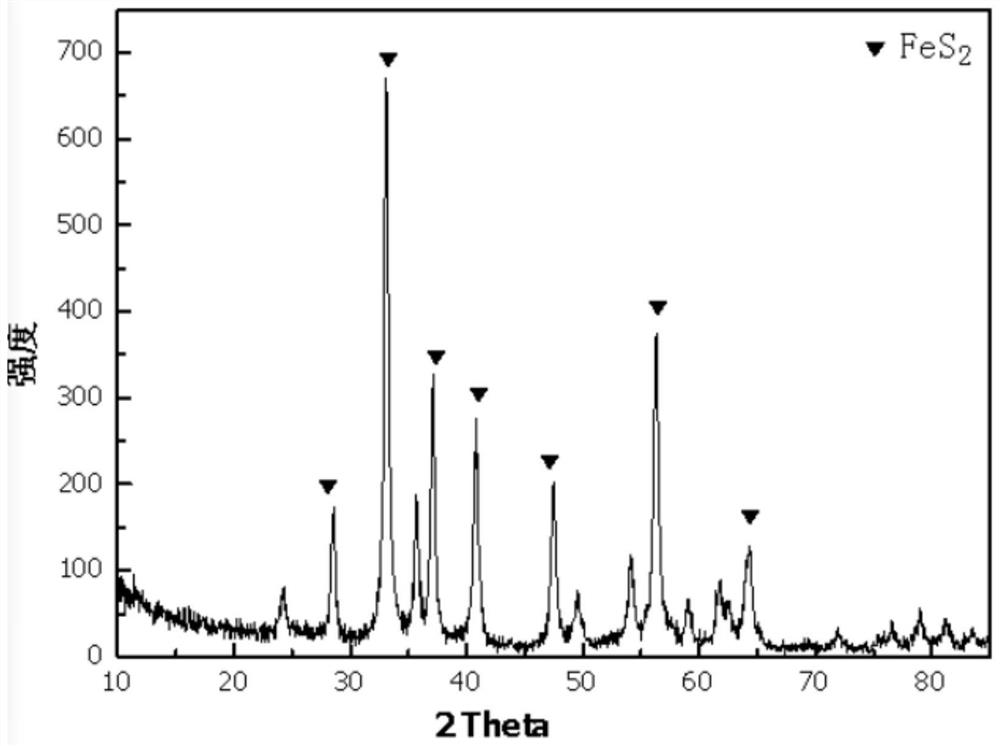

[0043] (3) solid-liquid separation, vacuum drying at a temperature of 70°C, catalyst 3 is obtained, and the X-ray polycrystalline powder diffraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com