Preparation process of high-quality titanium-based boron-doped diamond film electrode

A technology of boron-doped diamond and thin-film electrodes, which is applied in the field of preparation technology of titanium-based boron-doped diamond thin-film electrodes, can solve the problems of short life, inability to produce in a large area, and poor bonding force of titanium-based diamond electrodes, so as to improve the bonding force, Ensures electrical conductivity and workability, and improves macroscopic roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated by the following examples: According to the following examples, the present invention can be better understood. However, those skilled in the art can easily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the present invention, and should not and will not limit the present invention described in the claims.

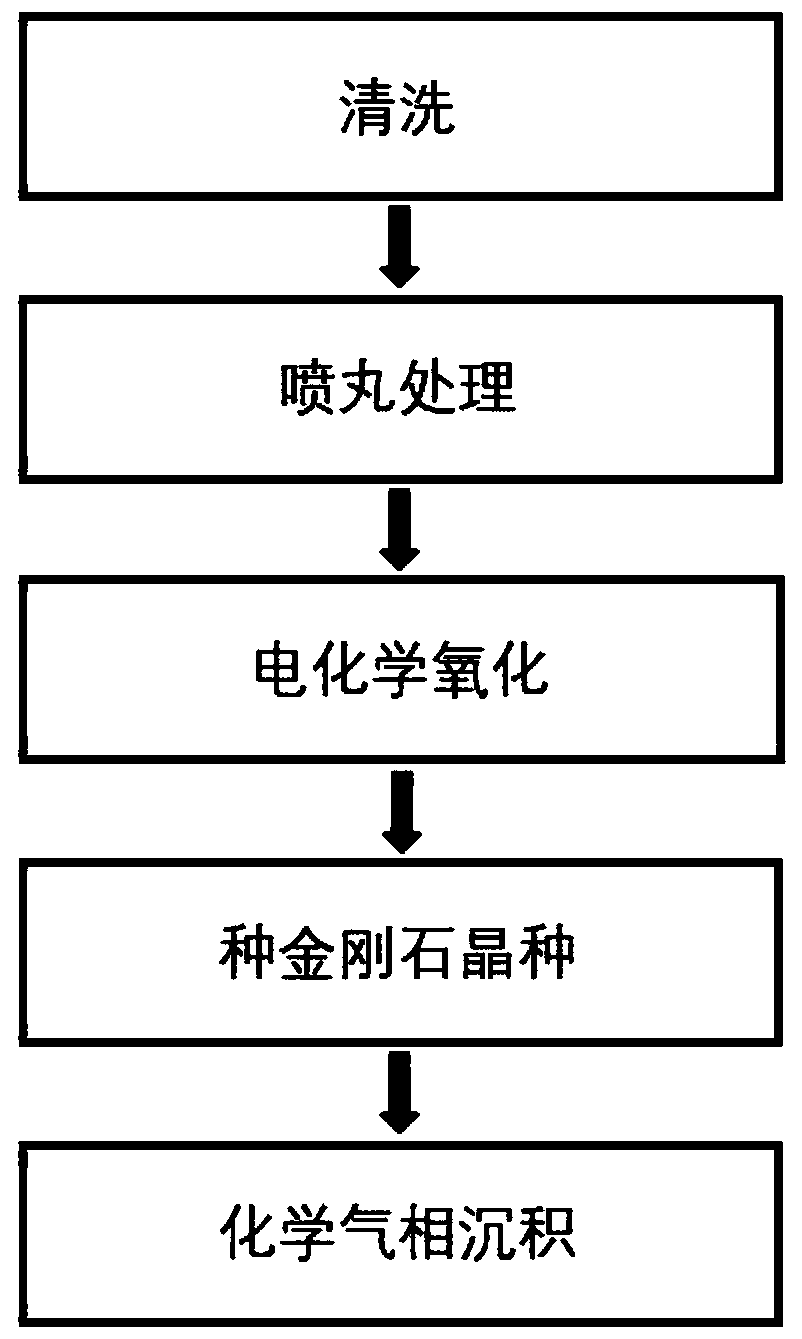

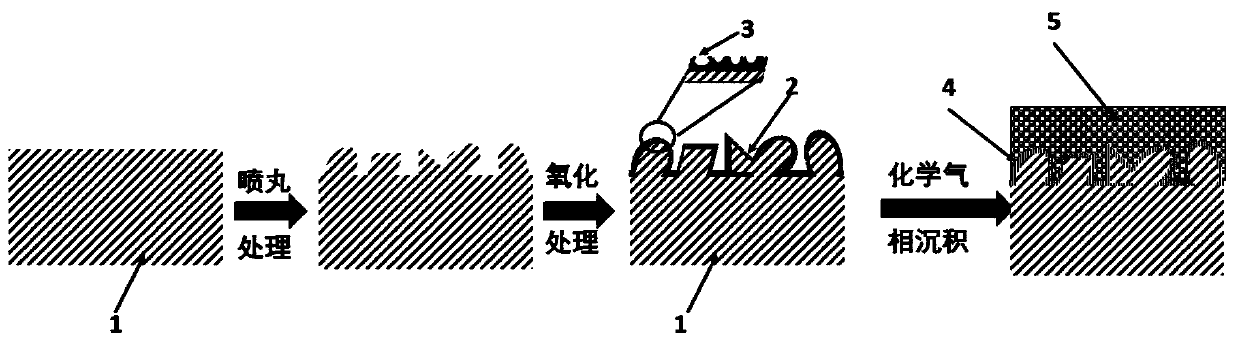

[0024] combine figure 1 and figure 2 As shown, a high-quality titanium-based boron-doped diamond film electrode preparation process includes the following specific steps:

[0025] (1), cleaning: cleaning the lining body, first, the lining body 1 is cleaned by a rolling brush, and then the lining body 1 is put into deionized water, sodium hydroxide, and acetone solution successively for ultrasonic cleaning for 1-3 minutes;

[0026] (2) Shot peening treatment: select ceramic shot peening with a particle size of 1-2000 μm, and use a shot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com