Ammonia decomposition hydrogen production catalyst and preparation method and application thereof

A catalyst, ammonia decomposition technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of low ammonia decomposition activity and easy stratification, achieve high ammonia decomposition efficiency, solve stratification, and optimize catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

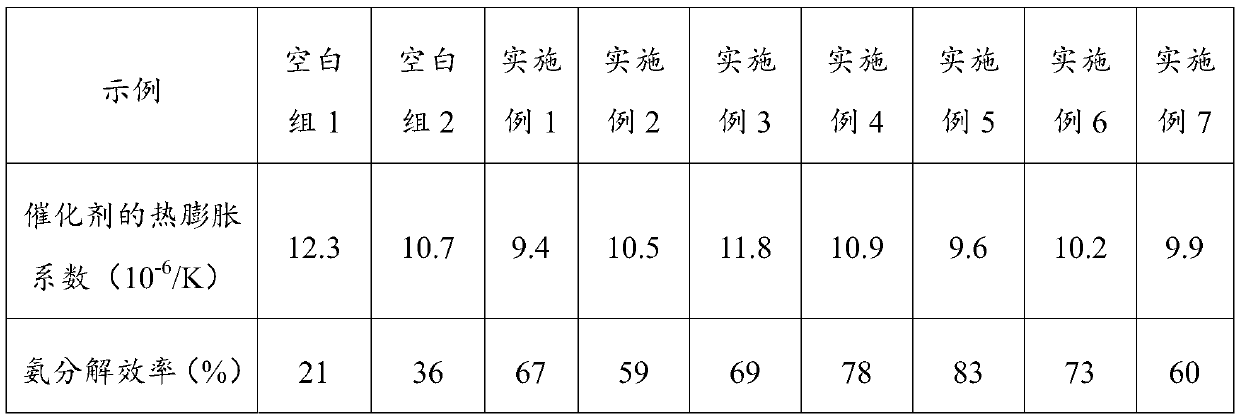

[0047] This embodiment provides a catalyst for hydrogen production by ammonia decomposition, including the active component ruthenium (Ru), and the carrier is a mixture of yttria stabilized zirconia and alumina (YSZ / Al 2 o 3 ); Ru, YSZ and Al 2 o 3 The mass ratio is 8:60:40 (the mass content of Ru in the carrier is ω=8%);

[0048] The preparation method of above-mentioned catalyst comprises,

[0049] (1) YSZ and Al 2 o 3 After the powder was ball milled at 250r / min for 12h, weigh 2g (m 1) into a crucible and dried at 100°C for 10 hours, then roasted at 1100°C for 2 hours, and set aside;

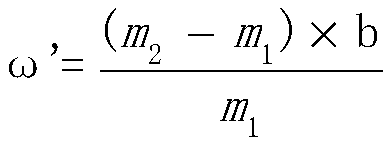

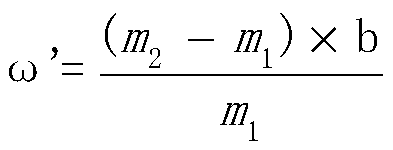

[0050] (2) preparation mass fraction is the precursor aqueous solution of 5% ruthenium (RuCl 3 ), wherein, RuCl in the aqueous solution of the precursor of ruthenium 3 The mass of X, RuCl 3 The mass fraction of Ru in is b; the YSZ / Al 2 o 3 Completely soak in the aqueous solution of the precursor of ruthenium for 1h, then dry at 100°C for 2h, then bake at 450°C for 15min, take it ou...

Embodiment 2

[0059] This embodiment provides a catalyst for hydrogen production by ammonia decomposition, including the active component nickel (Ni), carrier YSZ; the mass ratio of Ni to YSZ is 40:100 (the mass content of Ni in the carrier is ω=40%);

[0060] The preparation method of above-mentioned catalyst comprises,

[0061] (1) After YSZ powder is ball milled at 250r / min for 12h, weigh 2g (m 1 ) into a crucible and dried at 100°C for 10 hours, then roasted at 1100°C for 2 hours, and set aside;

[0062] (2) Prepare an aqueous solution of nickel precursor with a mass fraction of 10% (Ni(NO 3 ) 3 , where (Ni(NO 3 ) 3 Mass is X, (Ni(NO 3 ) 3 The mass fraction of Ni in the medium is b; YSZ is completely immersed in the nickel precursor aqueous solution for 1 h, then dried at 100 °C for 2 h, and then roasted at 450 °C for 15 min, and its mass is called m after taking it out 2 , then calculate the mass content (ω') of Ni in the YSZ carrier;

[0063] (3) Repeat step (2) until ω is the...

Embodiment 3

[0071] The present embodiment provides a kind of ammonia decomposition hydrogen production catalyst, comprises active component ruthenium (Ru), carrier YSZ / CeO 2 ; Ru, YSZ and CeO 2 The mass ratio is 6:50:50 (the mass content of Ru in the carrier is ω=6%);

[0072] The preparation method of above-mentioned catalyst comprises,

[0073] (1) YSZ and CeO 2 After the powder was ball milled at 250r / min for 12h, weigh 2g (m 1 ) into a crucible and dried at 100°C for 10 hours, then roasted at 1100°C for 2 hours, and set aside;

[0074] (2) preparation mass fraction is the precursor aqueous solution (RuCl 3 ), wherein, RuCl in the aqueous solution of the precursor of ruthenium 3 The mass of X, RuCl 3 The mass fraction of Ru in is b; the YSZ / CeO 2 Completely soak in the aqueous solution of the precursor of ruthenium for 40min, then dry at 100°C for 2h, then bake at 450°C for 15min, take it out and call its mass m 2 , and then calculate YSZ / CeO 2 The mass content of Ru in the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com