On-line leakage blocking device for detachable natural gas pipeline

A natural gas pipeline, detachable technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of easy corrosion of pipelines, natural gas leakage, waste of energy, etc., to improve reliability and safety , quick disassembly and assembly, and the effect of preventing explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

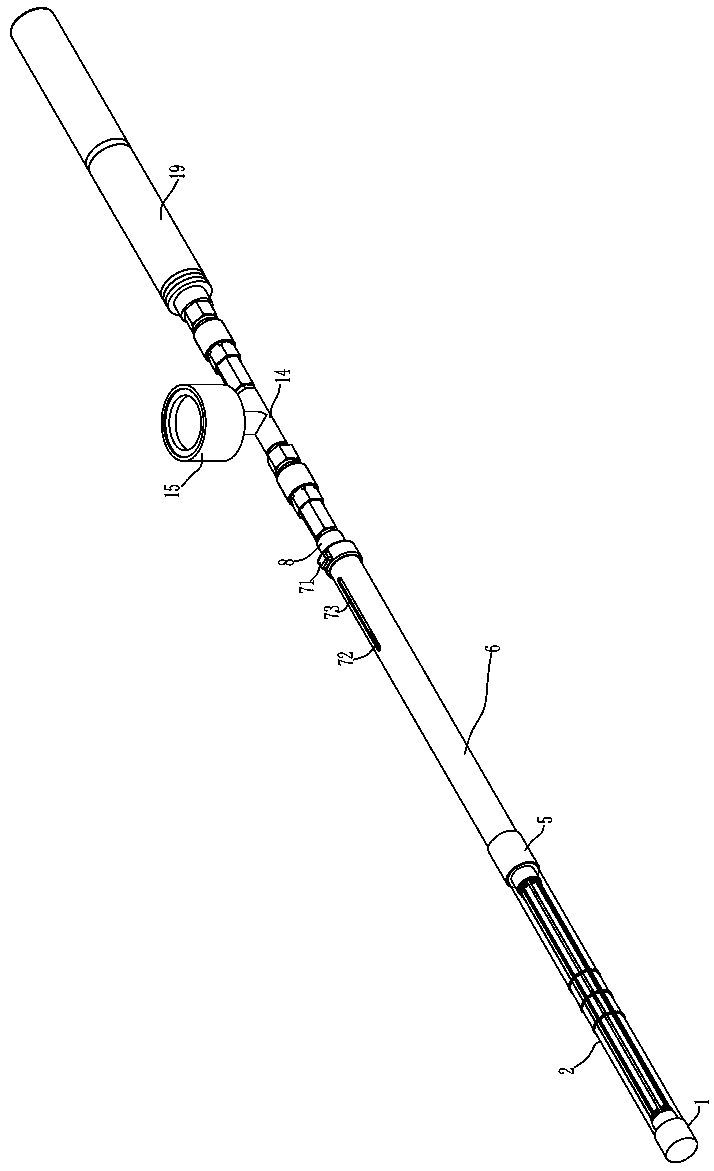

[0024] Embodiment one: the pipeline A20 position that needs repairing is as Figure 5 As shown, according to the diameter of the pipeline A20 to be repaired, the airbag 2 is selected, the bolt at the pipeline A20 is unscrewed, the front end of the present invention is put into the pipeline A20, and then the air compressor is manually operated to inflate the airbag 2. During the process, the air pressure gauge 15 can display the air pressure of the inflation. At this time, the air bag 2 gradually becomes larger and blocks the entire pipeline A20 under the action of the gas, thereby realizing the sealing of the pipeline A20. When the air pressure reaches the specified value of 3000pa, stop the inflation. Due to the action of the one-way valve B, the gas will not leak after stopping the inflation; the hand pushes the sleeve 6 to move forward, and the sleeve 6 acts on the rear end cover 5, the rear end The cover 5 squeezes the elastic support frame 3, so that the elastic support f...

Embodiment 2

[0025] Embodiment two: the pipeline B21 position that needs repairing is as Image 6 As shown, the difference between the present invention of Embodiment 2 and the present invention of Embodiment 1 is that the quick joint C9, the inner-to-outer joint C10 and the one-way valve B11 are removed. After the plugging is completed, the present invention does not affect the repair of the pipeline B21, so The air compressor can be removed, and the quick joint A18 to the front end cover 1 are all left in the pipeline A20 for plugging. At this time, the air pressure gauge 15 has the function of detecting the internal pressure of the present invention, and the plugging can be judged by observing the value of the air pressure gauge 15. Whether the leakage device leaks, the rest of the work process is exactly the same as that of Embodiment 1, and will not be described in detail here again.

[0026]The present invention is supplied with air by an air compressor. During work, the air compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com