Membrane type liquid-based thin layer cell tableting machine

A technology of thin-layer cell and slicer, applied in the field of slicer, can solve problems such as inconvenient operation, inaccurate test results, mixing, etc., and achieve the effects of convenient maintenance and operation, reliable work, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

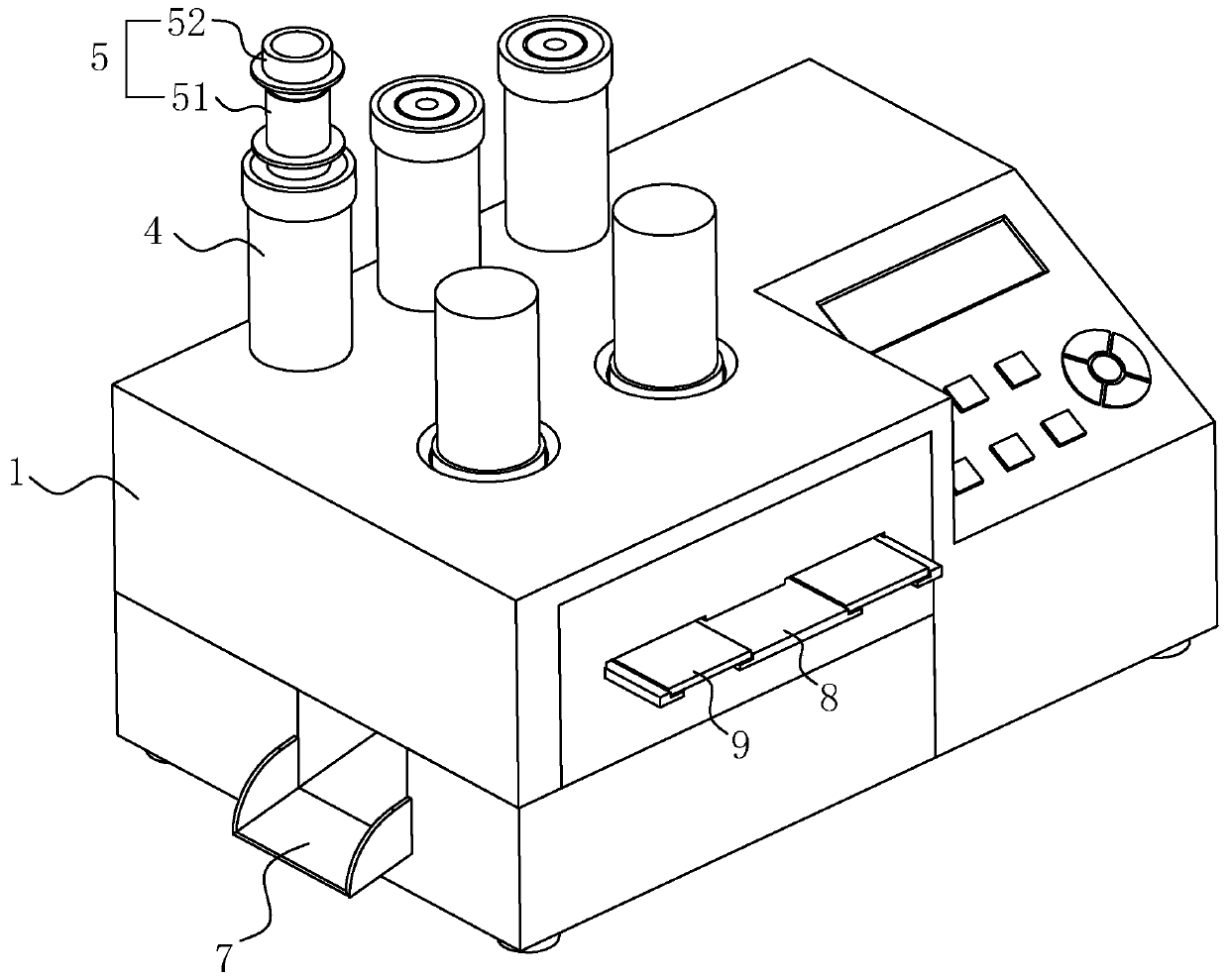

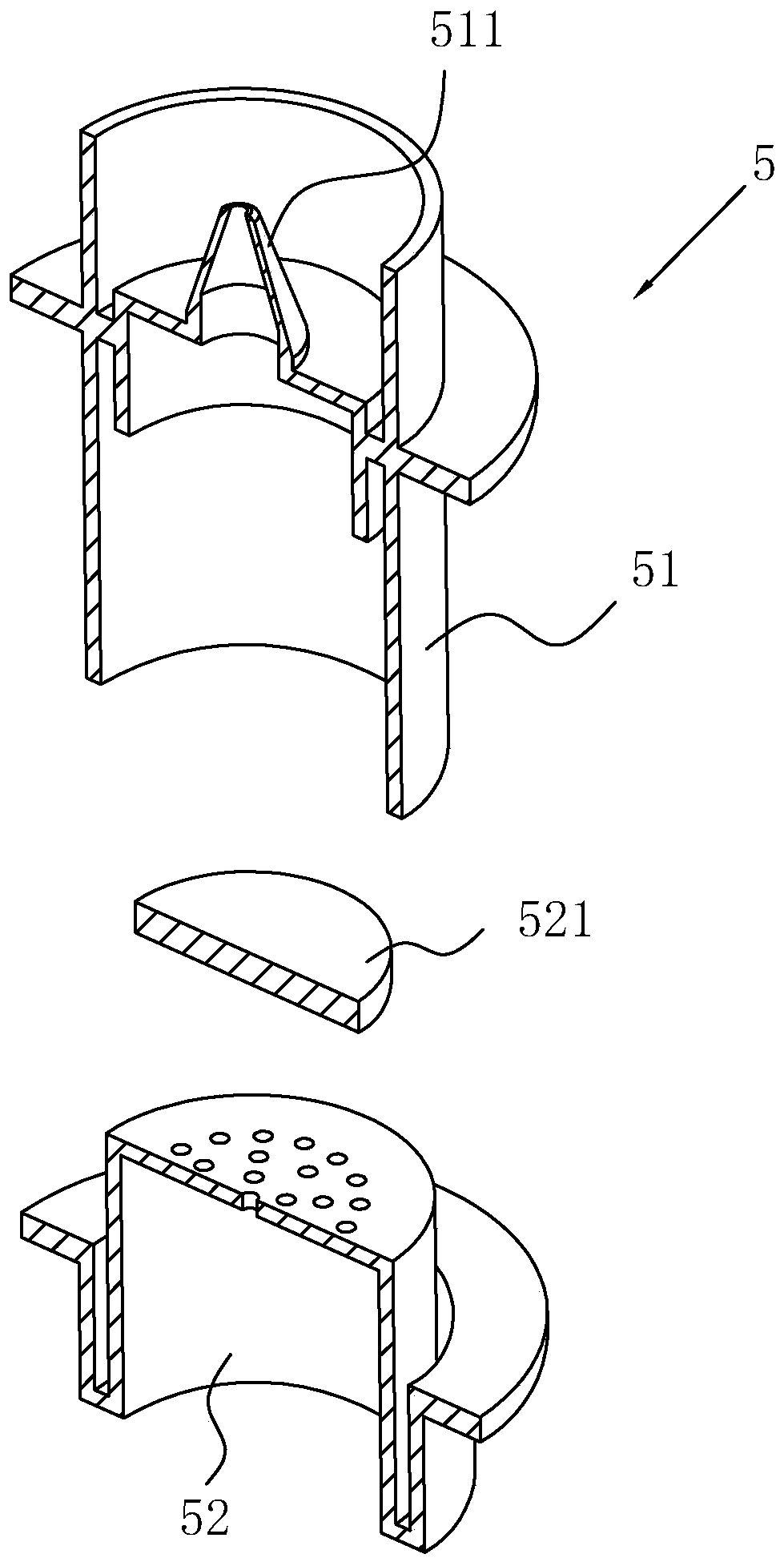

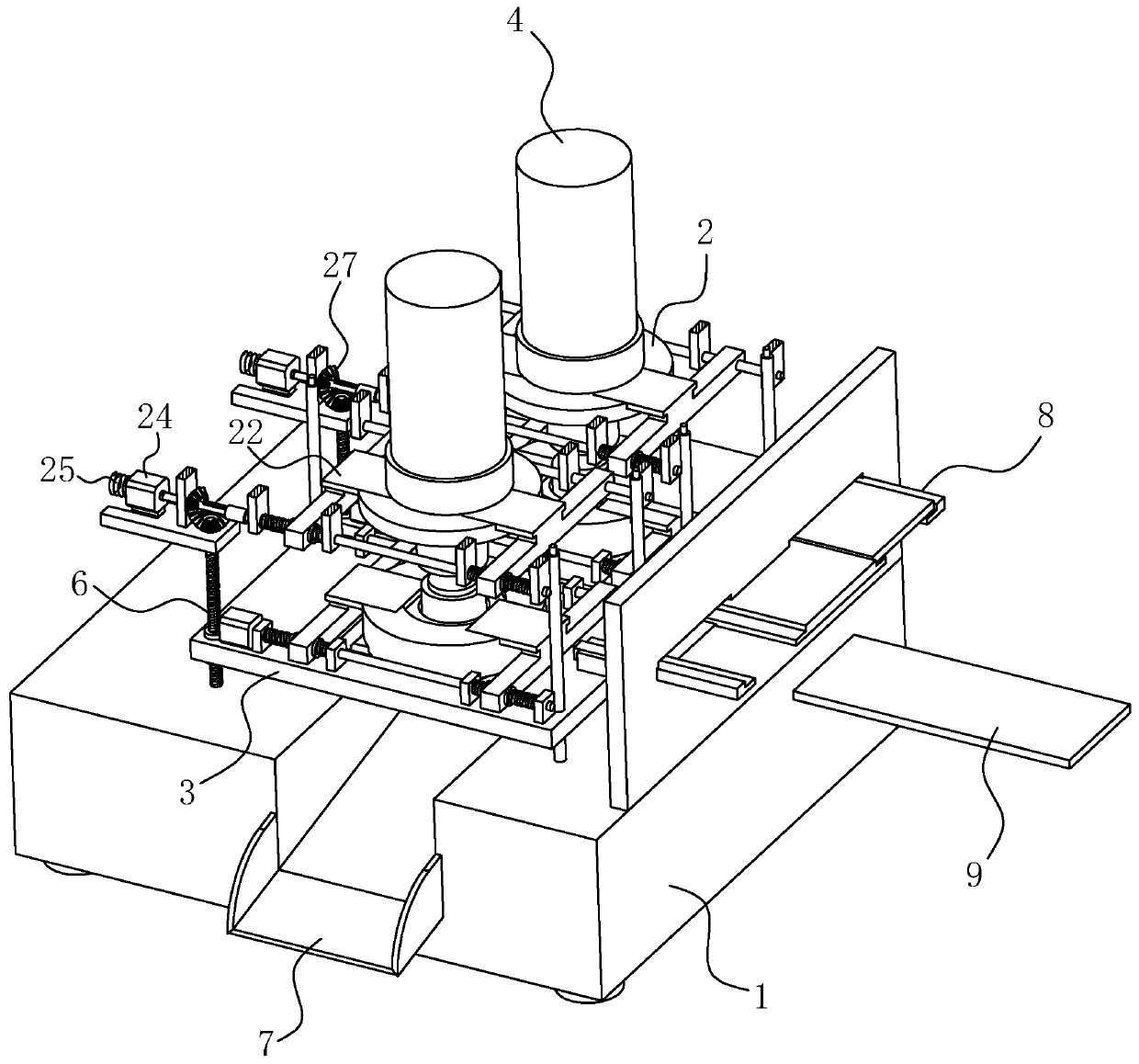

[0038] refer to figure 1 as well as figure 2, which is a membrane-type liquid-based thin-layer cell slicer disclosed in the present invention, includes a frame 1 and a filter membrane cup 5 arranged on the frame 1, and the filter membrane cup 5 includes a liquid-taking tube 51 that is nested with each other and The liquid storage pipe 52, the liquid collection pipe 51 is sleeved on the outside of the liquid storage pipe 52, the liquid collection pipe 51 is provided with a tapered pipe 511 inserted into the container 4, the large diameter end of the tapered pipe 511 and the inner wall of the liquid collection pipe 51 Fixed, the top of the liquid storage tube 52 is provided with a liquid storage film 521, and the liquid storage film 521 has a certain degree of air permeability. . The frame 1 is also provided with an air suction device that communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com