Antenna board and manufacturing method thereof

A manufacturing method and antenna board technology, applied in the direction of antenna, antenna coupling, antenna components, etc., can solve the problems of slow signal transmission, damage to product functions, and inability to weld components, so as to improve production yield and improve anti-interference. the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

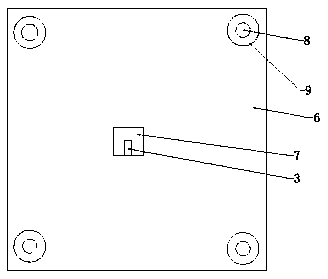

[0036] The most critical idea of the present invention is to place the PCB board for sending and receiving antenna signals between two grounded metal plates, and set a hollow slot on one of the metal plates, so that the antenna signal can only be sent and received through the hollow slot, reducing interference .

[0037] In order to discuss the feasibility of the concept of the present invention, according to the technical content, structural features, achieved goals and effects of the present invention, it will be described in detail in conjunction with the implementation and accompanying drawings.

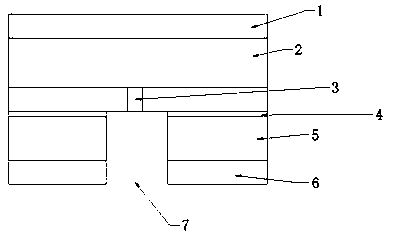

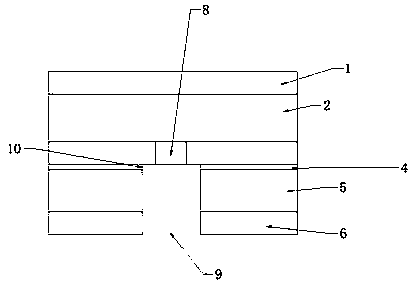

[0038] see figure 1 , figure 2 as well as image 3 , an antenna board, comprising a grounded first metal plate 1, a PCB board 3 for transmitting and receiving antenna signals, and a grounded second metal plate 6, the PCB board 3 is located between the first metal plate 1 and the second metal plate 6 Between the two metal plates 6 ; the second metal plate 6 is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com