Small multi-axis linkage ultrasonic vibration---electromagnetic auxiliary increasing and decreasing material processing device

A technology of ultrasonic vibration and multi-axis linkage, applied in the direction of metal material coating process, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems affecting the performance of workpiece materials, improve processing efficiency and precision, and refine metal Effects that are less difficult to compose and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used to explain the relationship between the components in a certain posture (as shown in the accompanying drawings). Relative positional relationship, movement conditions, etc., if the specific posture changes, the directional indication will also change accordingly.

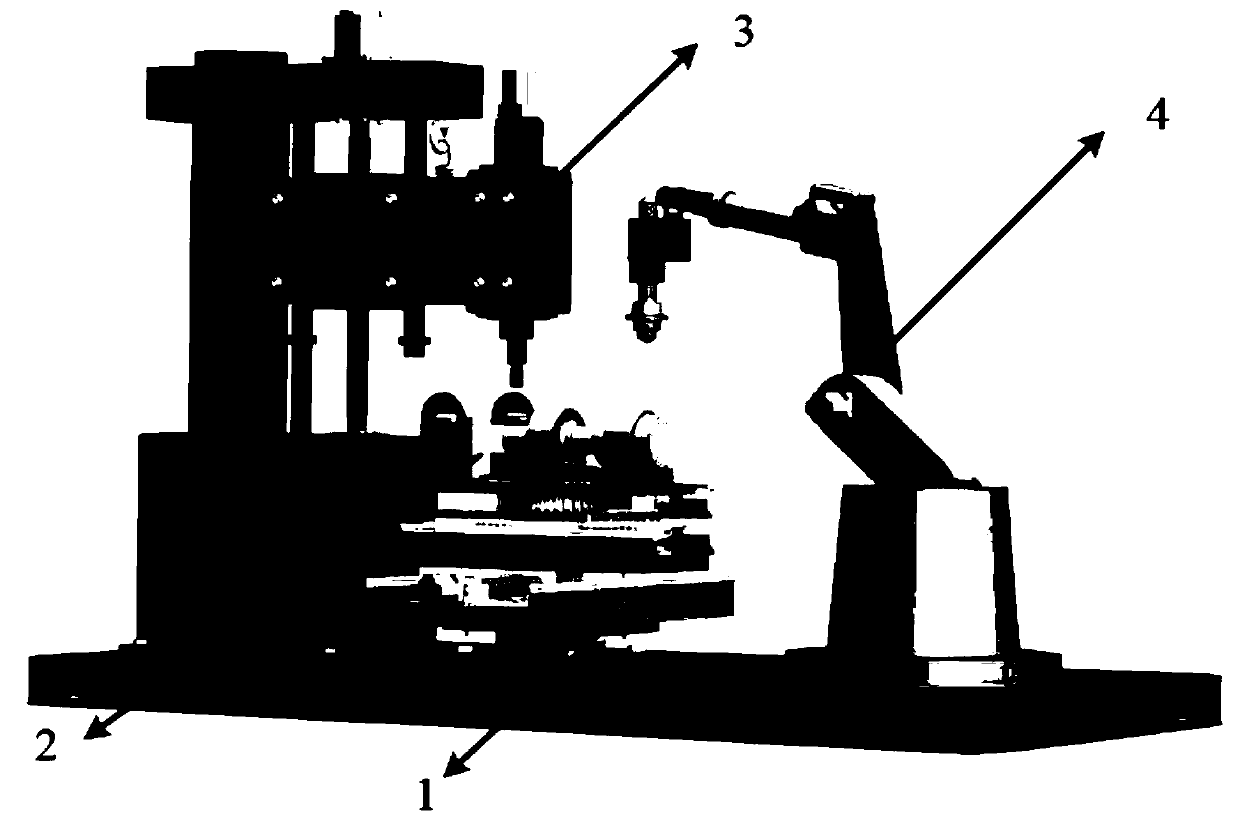

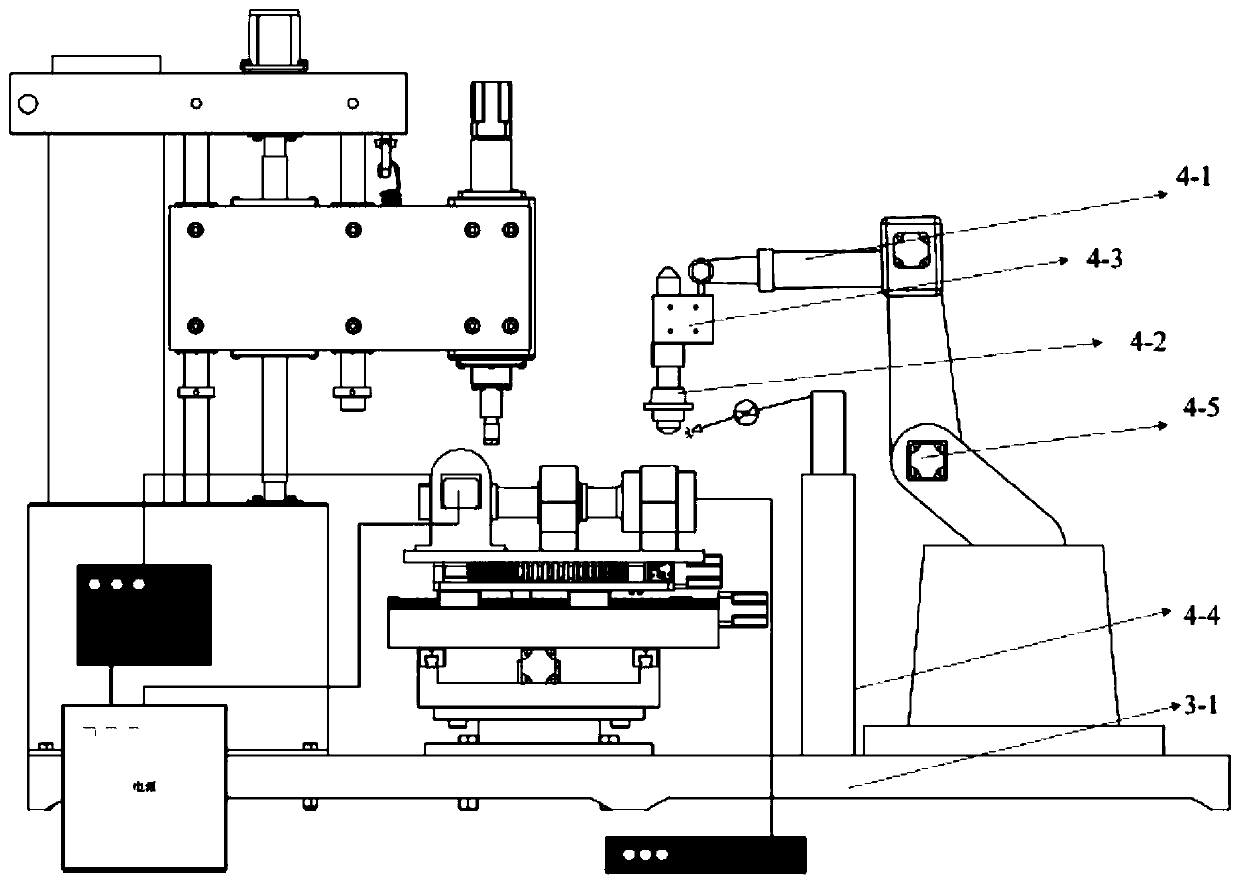

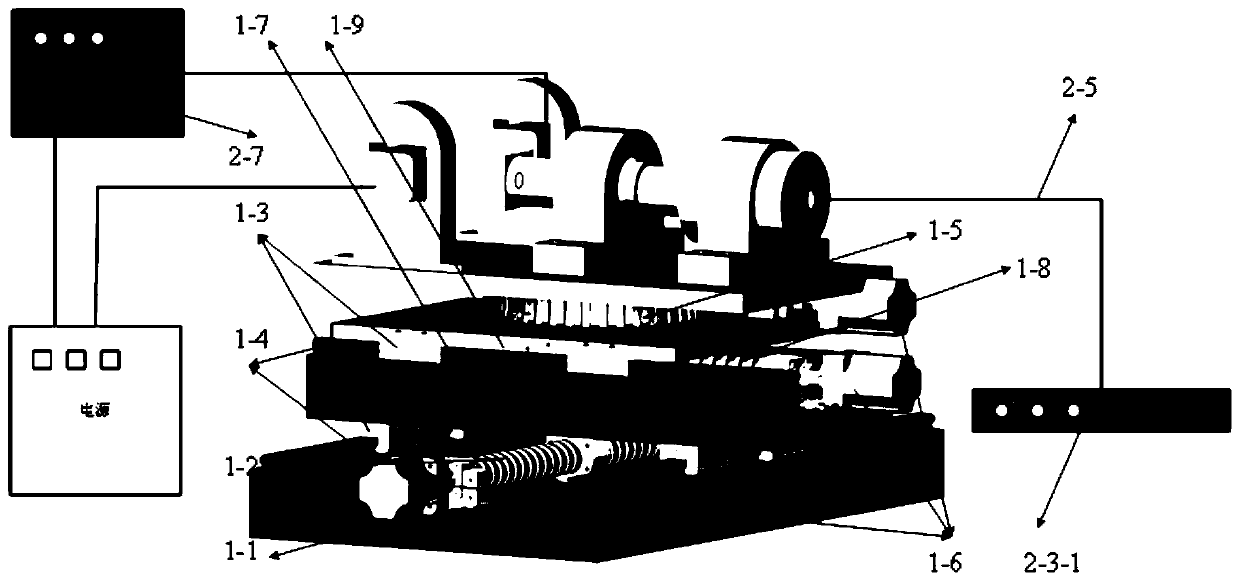

[0026] Such as Figure 1 to Figure 7 As shown, the present invention provides a small multi-axis linkage ultrasonic vibration-electromagnetic assisted material addition and subtraction processing device, including a steering mobile table 1, an ultrasonic vibration-electromagnetic auxiliary device 2, a milling-grinding composite processing device 3 and a laser cladding Device 4 is the main structure of the device. The milling-grinding compound processing device 3 is provided with a machine tool base 3-1 to provide an installation foundation for the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com