Robot precision control method coupling kinematics and rigidity parameter identification

A kinematic parameter and parameter identification technology, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of insufficient adaptability to processing tasks, difficulty in ensuring the accuracy of offline positioning error prediction methods, etc., to improve prediction capabilities and improve operations. Accuracy, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

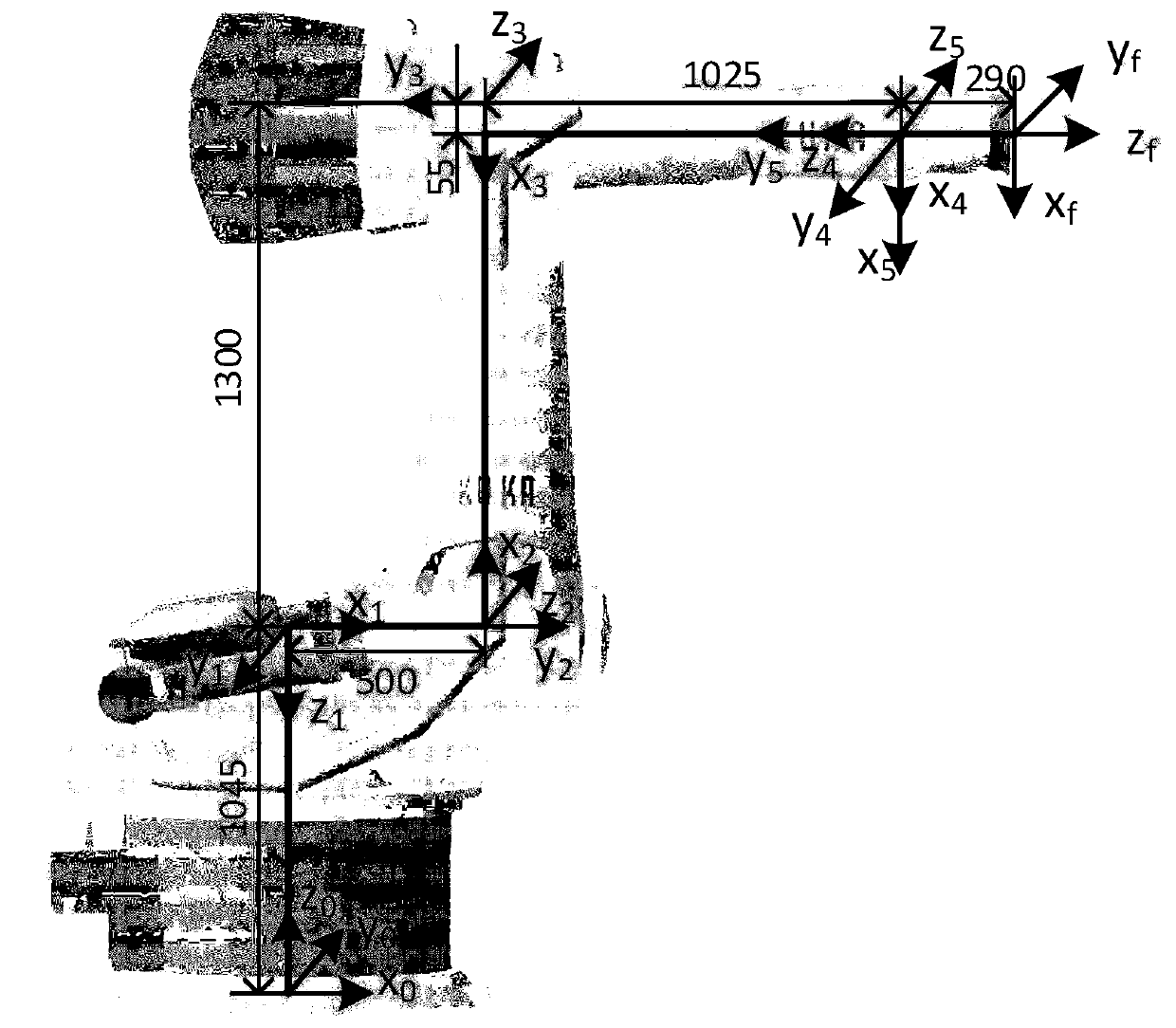

[0034] Step 1: Put the laser tracker in a suitable position for easy measurement. A laser tracker is used to measure and construct a coordinate system consisting of the robot base coordinate system Base, the flange coordinate system Flange, the tool coordinate system Tool, and the six-dimensional force sensor coordinate system Force.

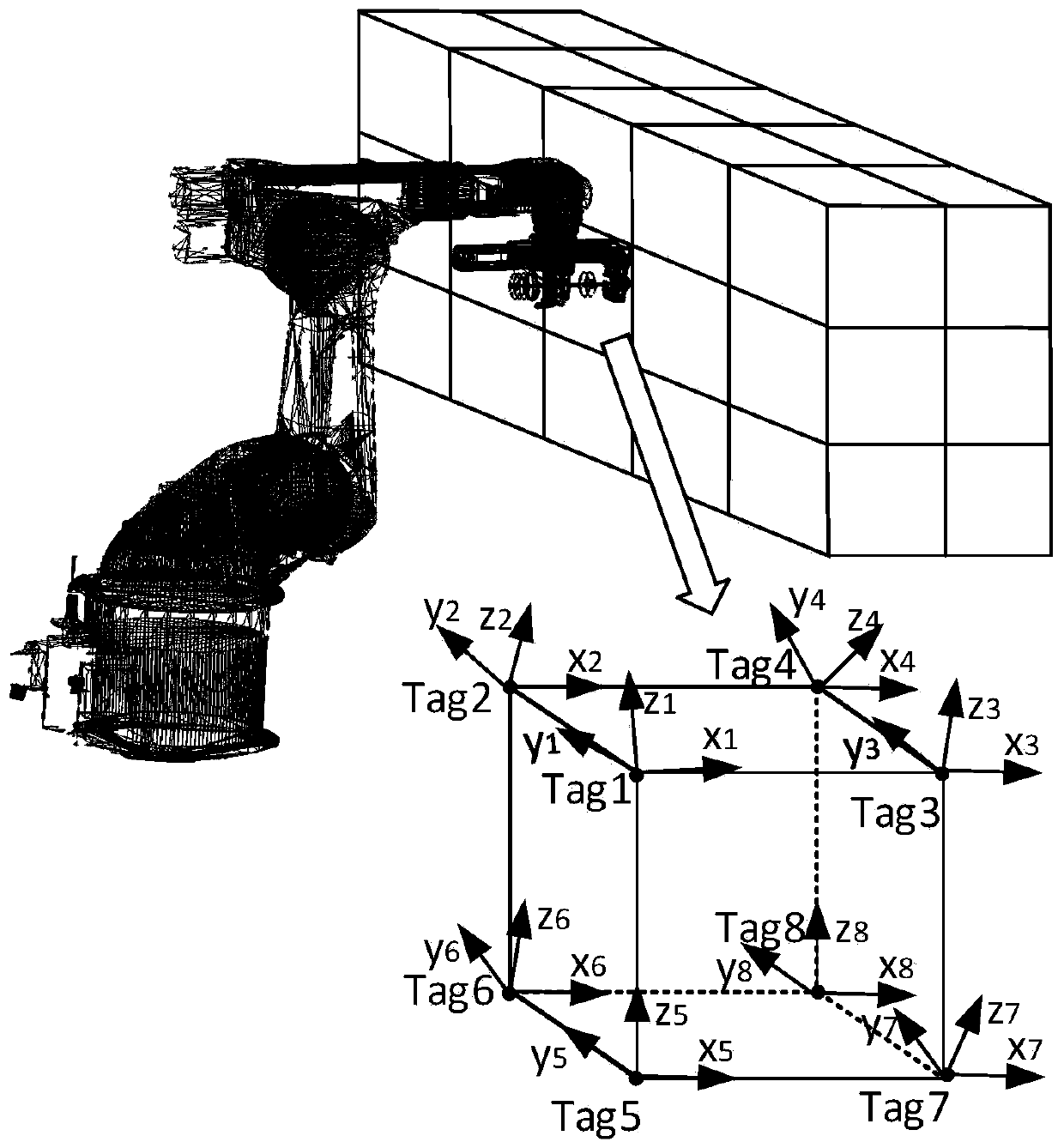

[0035] Step 2: In the effective working space of the robot, the working space is divided into a series of cubic grids according to the given grid step size, and the fixed points of the grids are used as the target positions of sampling points for kinematics and joint stiffness identification (see figure 1 In Tag1 to Tag8, where X i , Y i ,Z iare respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com