Water treatment apparatus for chemically polluted water areas

A water treatment device and technology of chemical pollution, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

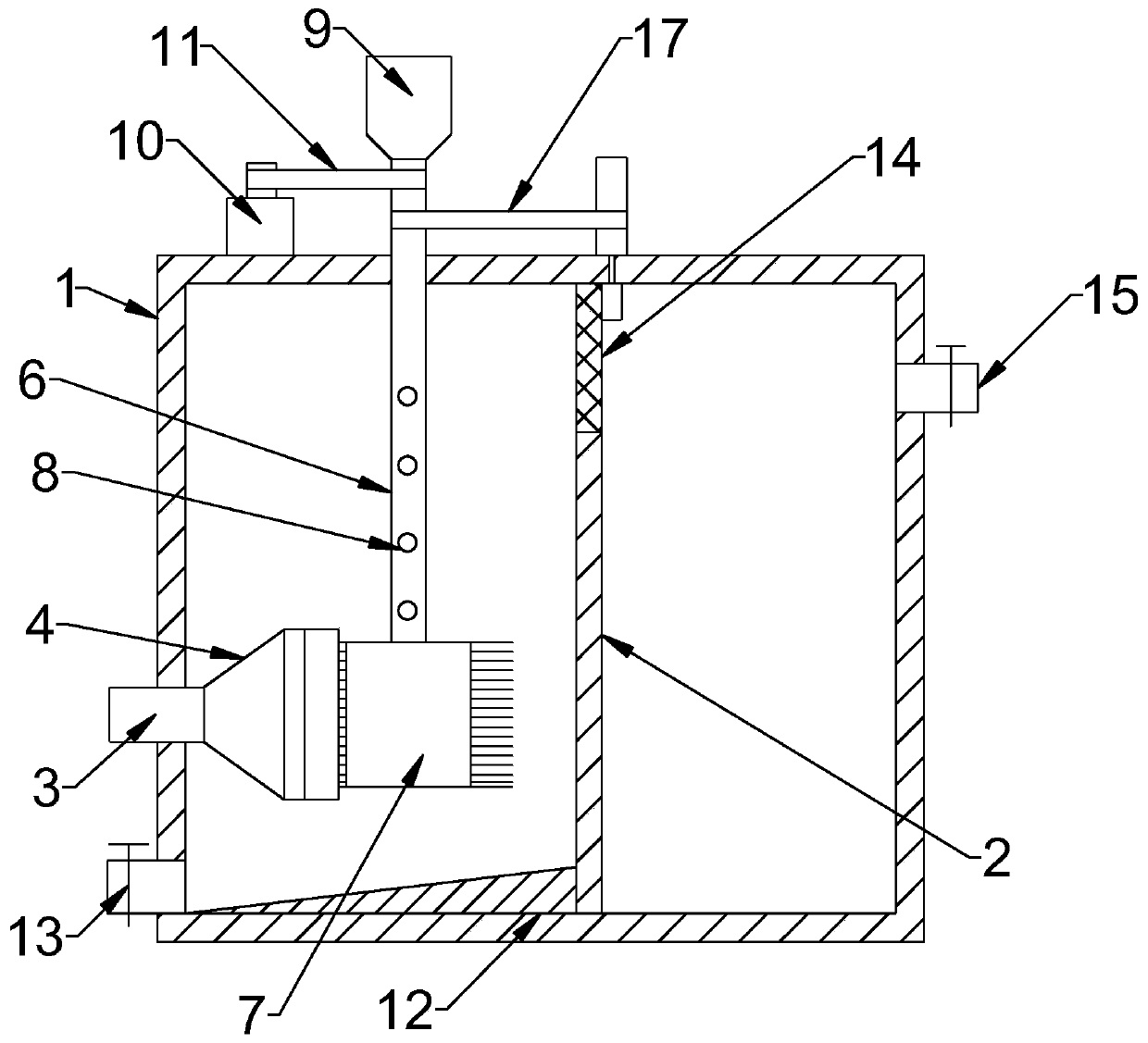

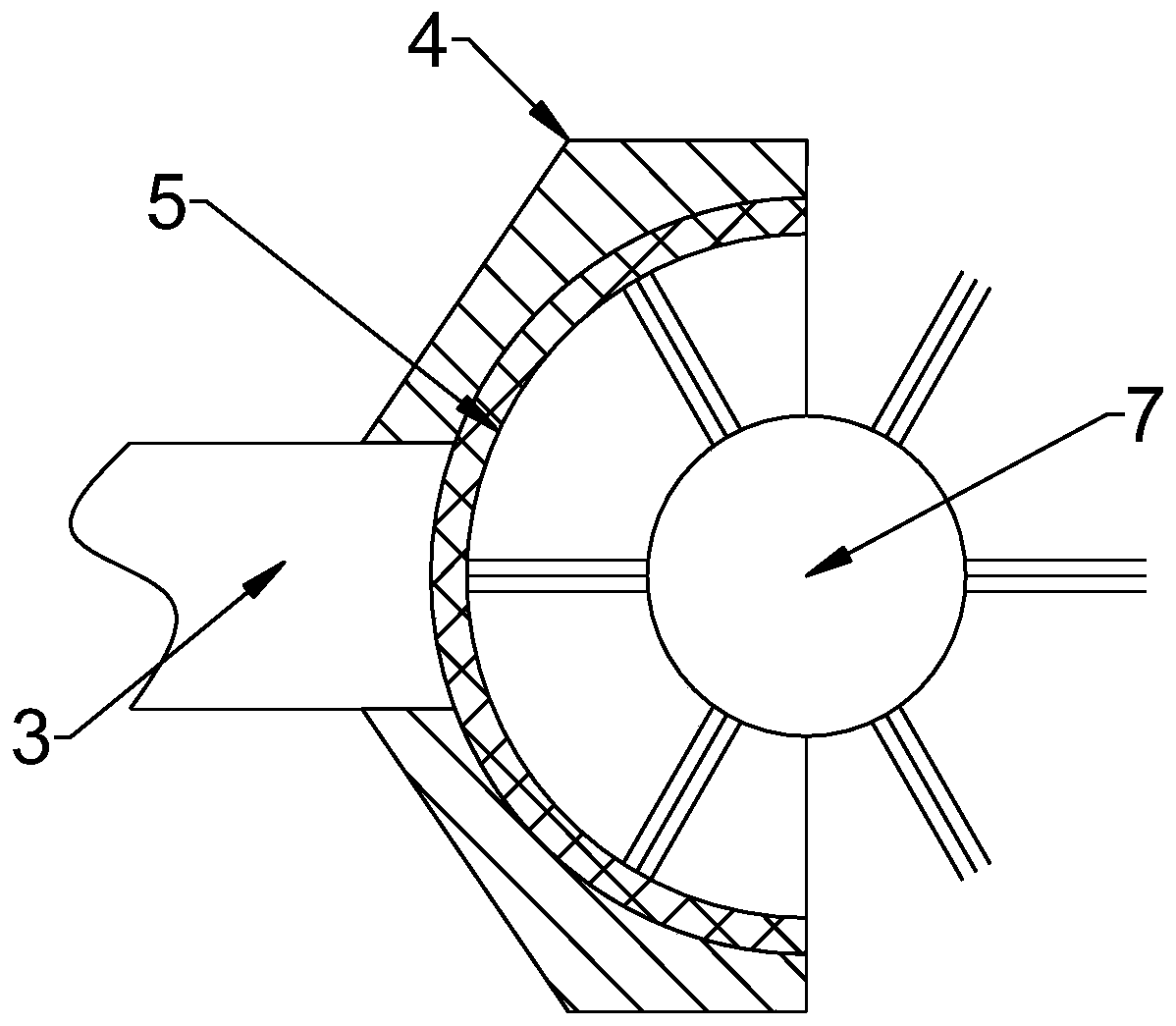

[0022] see Figure 1~2 , in an embodiment of the present invention, a water treatment device for chemically polluted waters includes a housing 1, on which a water inlet structure and a reagent adding structure for treating chemical pollution are communicated, and the housing 1 1. A precipitation treatment chamber and a water outlet chamber are separated by a partition 2. The upper part of the partition 2 is inlaid with a fine mesh plate 14 for connecting the precipitation treatment chamber and the water outlet chamber. The reagent adding structure is driven to rotate by a driving motor 10 and is connected with Water intake structure activity coordination.

[0023] The driving motor 10 is a servo motor, which is continuously forward and reverse after starting.

[0024] The water inlet structure penetrates into the housing 1 through one side of the precipitation treatment chamber, the reagent addition structure extends through the top of the precipitation treatment chamber and ...

Embodiment 2

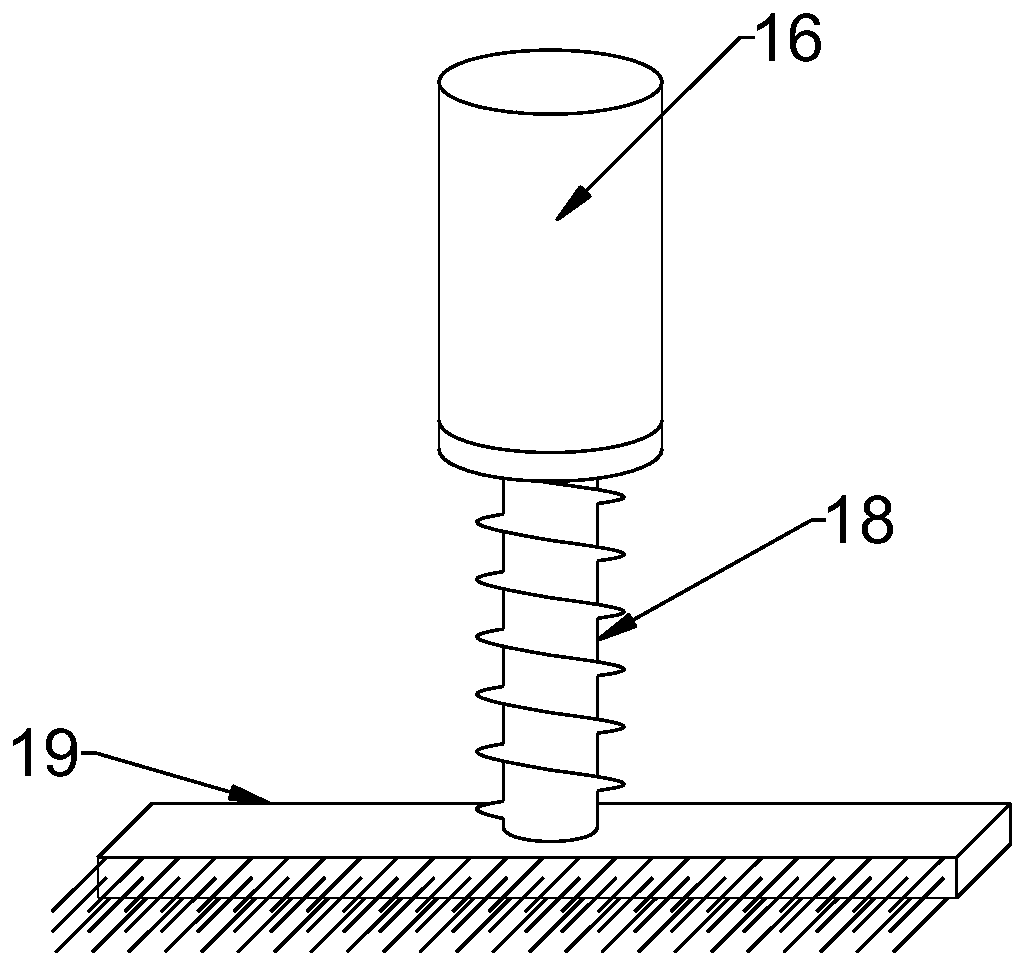

[0029] see figure 1 and 3 , in the embodiment of the present invention, a water treatment device for chemically polluted waters, on the basis of embodiment 1, a cleaning mechanism for removing dirt on the surface of the fine mesh plate 14 is connected above the side of the water outlet chamber, The cleaning mechanism is connected to the rotating pipeline 6 for transmission.

[0030] The cleaning mechanism includes a rotating sleeve 16 rotatably arranged on the housing 1 and a lifting rod 18 movably fitted at the lower end of the rotating sleeve 16. The rotating sleeve 16 is rotatably connected to the upper end of the housing 1 through a sealed bearing, and the The lower end of the rotating sleeve 16 communicates with the water outlet cavity, and the upper peripheral part of the rotating sleeve 16 and the upper peripheral part of the rotating pipe 6 are connected and driven through the second transmission belt 17; the lifting rod 18 is movably connected to the rotating sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com