High-thermal-conductivity die-casting magnesium alloy and manufacturing method thereof

A manufacturing method and high thermal conductivity technology, applied in the field of die-casting magnesium alloy and its manufacturing, can solve problems not related to mechanical properties, optimization, etc., to achieve the effect of improving mechanical properties at room temperature and high temperature, increasing fluidity, and reducing aluminum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1

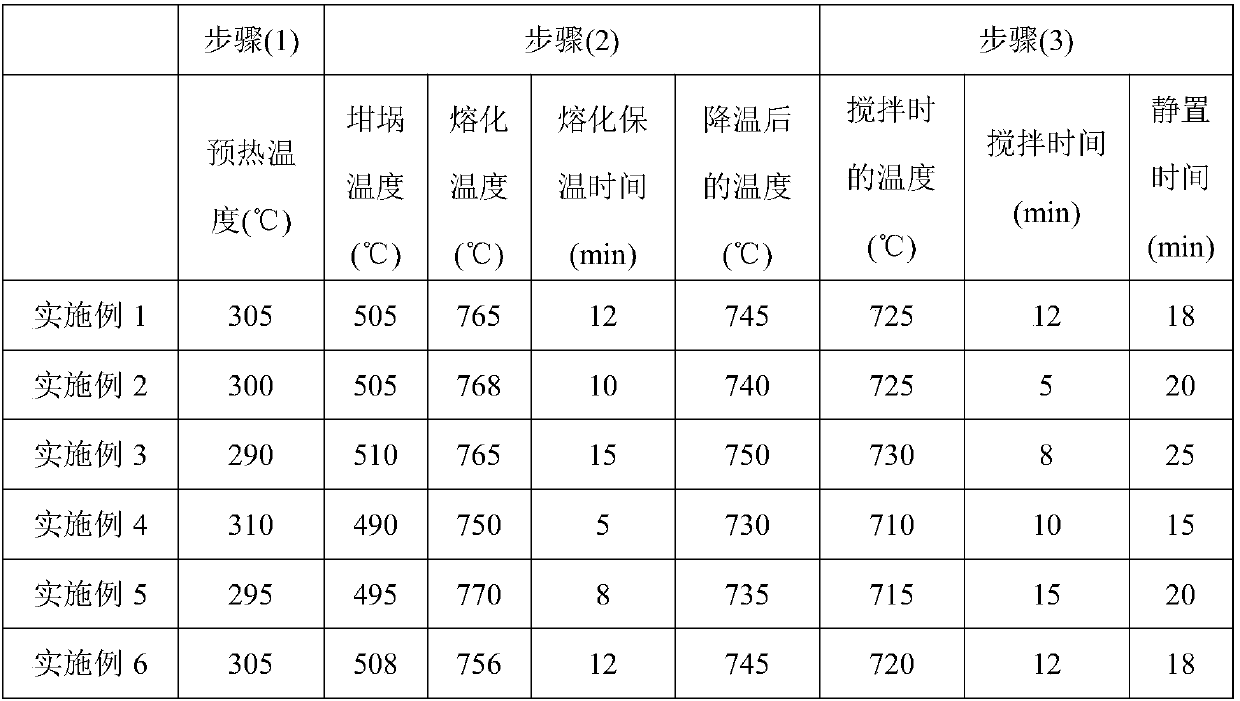

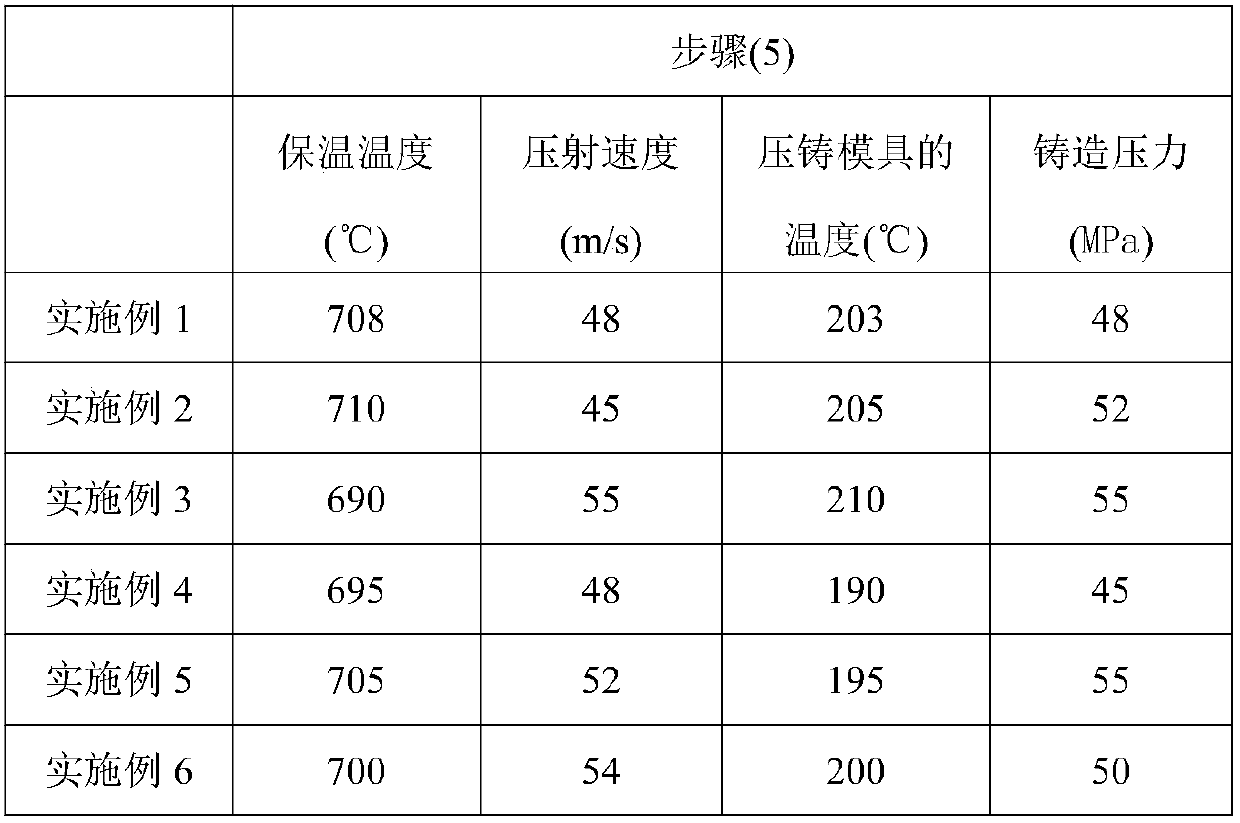

[0046]Table 1 lists the mass percentage of each chemical element in the high thermal conductivity die-casting magnesium alloy of Examples 1-6 and the AZ91 magnesium alloy of Comparative Example 1.

[0047] Table 1. (wt%, the balance is Mg and other unavoidable impurities)

[0048] Al La Sr mn Zn Example 1 6 5 0.3 0.5 0 Example 2 5 7 0.8 0.4 0 Example 3 5 6 1.0 0.2 0 Example 4 7 8 0.4 0.3 0 Example 5 5.5 7.5 0.9 0.25 0 Example 6 6.5 5.5 0.5 0.45 0 Comparative example 1 9

0

0

0.3 1

[0049] The high heat conduction die-casting magnesium alloy of embodiment 1-6 adopts following steps to make:

[0050] (1) Put the crucible into the heating furnace to preheat to 300°C±10°C, and then spray the release agent on the inner wall of the crucible;

[0051] (2) When the temperature of the crucible reaches 500°C±10°C, put the pure magnesium ingot into the crucible and pass it into SF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com