Lightweight high-performance parallel flow type evaporator core

An evaporator core, high-performance technology, used in evaporators/condensers, refrigeration and liquefaction, tubular elements, etc., can solve the problems of reduced corrosion resistance of thin walls, reduced refrigerant flow on the refrigerant side, insufficient cooling capacity, etc. The effect of brazing welding rate, improving heat transfer capacity and increasing window opening angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

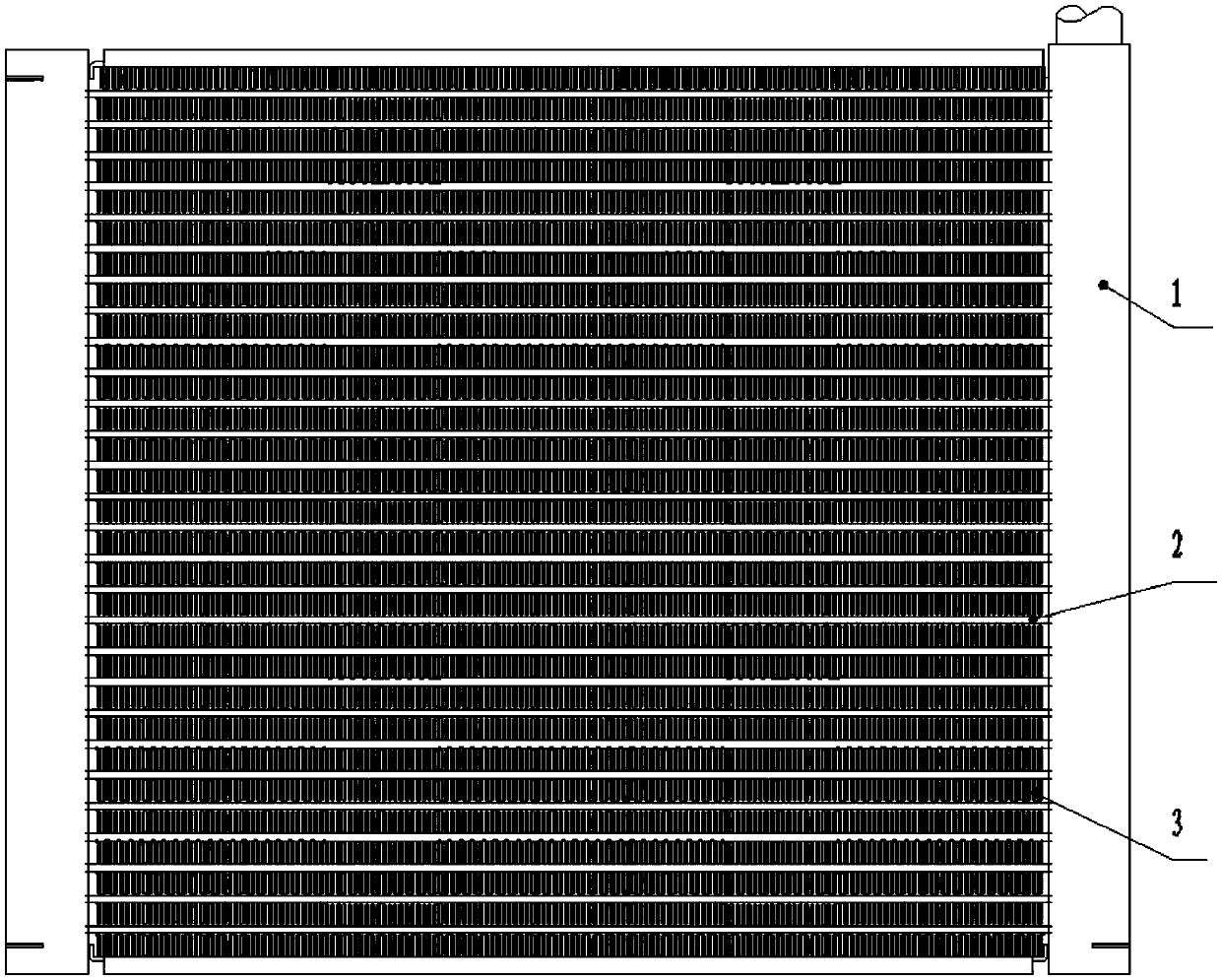

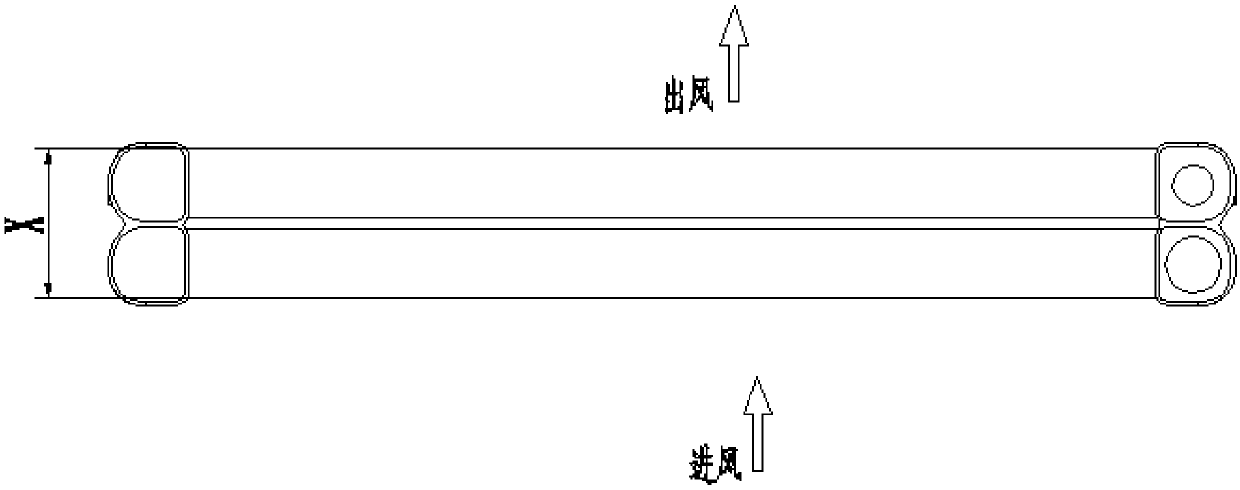

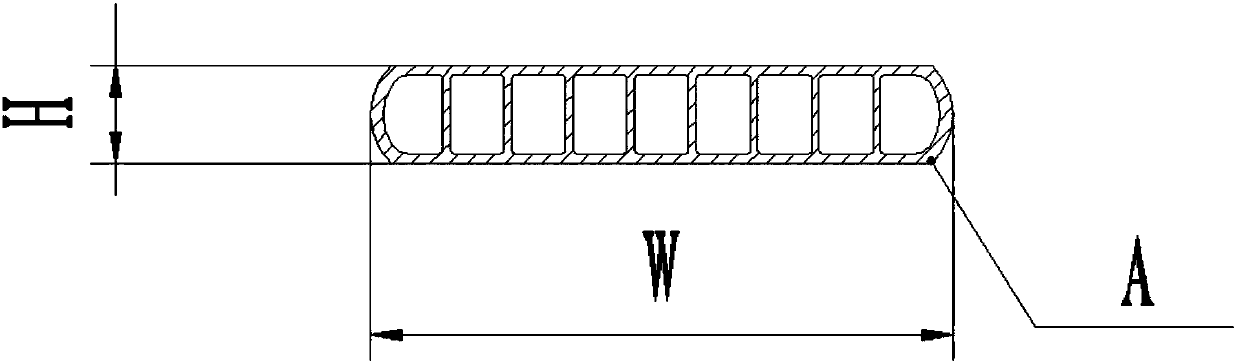

[0025] see Figure 1 to Figure 6 , in a preferred embodiment, the lightweight high-performance parallel-flow evaporator core includes flat tubes and fins arranged on the flat tubes, the thickness of the core is X, 28mm≤X<34mm; the flat tubes The thickness is 2.3-2.4mm, the wall thickness (side wall thickness) of the flat tube is 0.18-0.25mm, the width of the flat tube is 14-16mm, the opening angle of the fin is 32°-38°, and the wave height (height) is 4.5-5.5mm . In a preferred embodiment, the thickness of the flat tube is 2.35 mm, the thickness of the flat tube is 0.18 mm, and the wave height of the fin is 5 mm. Increase the thickness of the flat tube to 2.35mm, reduce the wall thickness of the flat tube to 0.18mm to increase the inner hole area of the flat tube, ensure the area of a single flat tube refrigerant channel, and reduce the fin wave height to 5mm to increase the flat tube on the windward surface Quantity to ensure the entire core flow to the area.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com