Production technique of quercetin beverage and production technique of onion fermented product

A production process and technology for fermented products, which is applied in the production process field of onion beverages and onion fermented products, and can solve problems such as mildew cycle and mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

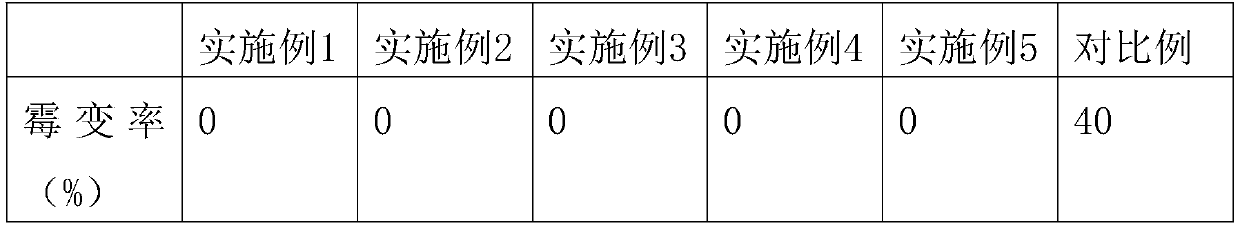

Examples

Embodiment 1

[0029] Embodiment 1: produce 100 kilograms of onion element drinks as example,

[0030] 90 kilograms of drinking water, then add 42 gram of sodium iso-VC, stir for subsequent use, 10 kilograms of drinking water add 300 grams of L malic acid, 250 grams of anhydrous citric acid are made into organic acid solution, fresh without rot, the onion without disease ( Processed) 100 kg peeled and washed, each onion is divided into four parts, then sliced, put into the reserve solution, soak for 2 hours at room temperature, put into the organic acid solution and continue to soak for 24 hours, then heat to boil, slightly boil for two After 1 hour, add water to keep the total amount extracted, and prepare the raw material extract, add pure water and bacteria to the honey for 24 hours for standby; put the raw material extract and honey fermentation enzyme into the barrel together, ferment at room temperature for 3 days, after two times Filter, filter with 80 mesh filter sieves for the first...

Embodiment 2

[0031] Embodiment 2: produce 100 kilograms of onion element drinks as example,

[0032] 90 kilograms of drinking water, then add 42 gram of sodium iso-VC, stir for subsequent use, 10 kilograms of drinking water add 300 grams of L malic acid, 250 grams of anhydrous citric acid are made into organic acid solution, fresh without rot, the onion without disease ( Processed) 100 kg peeled and washed, each onion is divided into four parts, then sliced, put into the reserve solution, soak for 2 hours at room temperature, put into the organic acid solution and continue to soak for 24 hours, then heat to boil, slightly boil for two After 1 hour, add water to keep the total amount extracted, and prepare the raw material extract, add pure water and bacteria to the honey for 24 hours for standby; put the raw material extract and honey fermentation enzyme into the barrel together, ferment at room temperature for 3 days, after two times Filter, filter with 80 mesh filter sieves for the first...

Embodiment 3

[0033] Embodiment 3: produce 100 kilograms of onion element drinks as example,

[0034]90 kilograms of drinking water, then add 42 gram of sodium iso-VC, stir for subsequent use, 10 kilograms of drinking water add 300 grams of L malic acid, 250 grams of anhydrous citric acid are made into organic acid solution, fresh without rot, the onion without disease ( Processed) 100 kg peeled and washed, each onion is divided into four parts, then sliced, put into the reserve solution, soak for 2 hours at room temperature, put into the organic acid solution and continue to soak for 24 hours, then heat to boil, slightly boil for two After 1 hour, add water to keep the total amount extracted, and prepare the raw material extract, add pure water and bacteria to the honey for 24 hours for standby; put the raw material extract and honey fermentation enzyme into the barrel together, ferment at room temperature for 3 days, after two times Filter, filter with 80 mesh filter sieves for the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com