Pinellia ternate processing method

A processing method, pinellia technology, applied in the direction of pharmaceutical formula, plant raw materials, plant/algae/fungus/moss components, etc., can solve the problems of high sulfur content and loss of active ingredients, so as to reduce sulfur dioxide residue, reduce toxicity, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

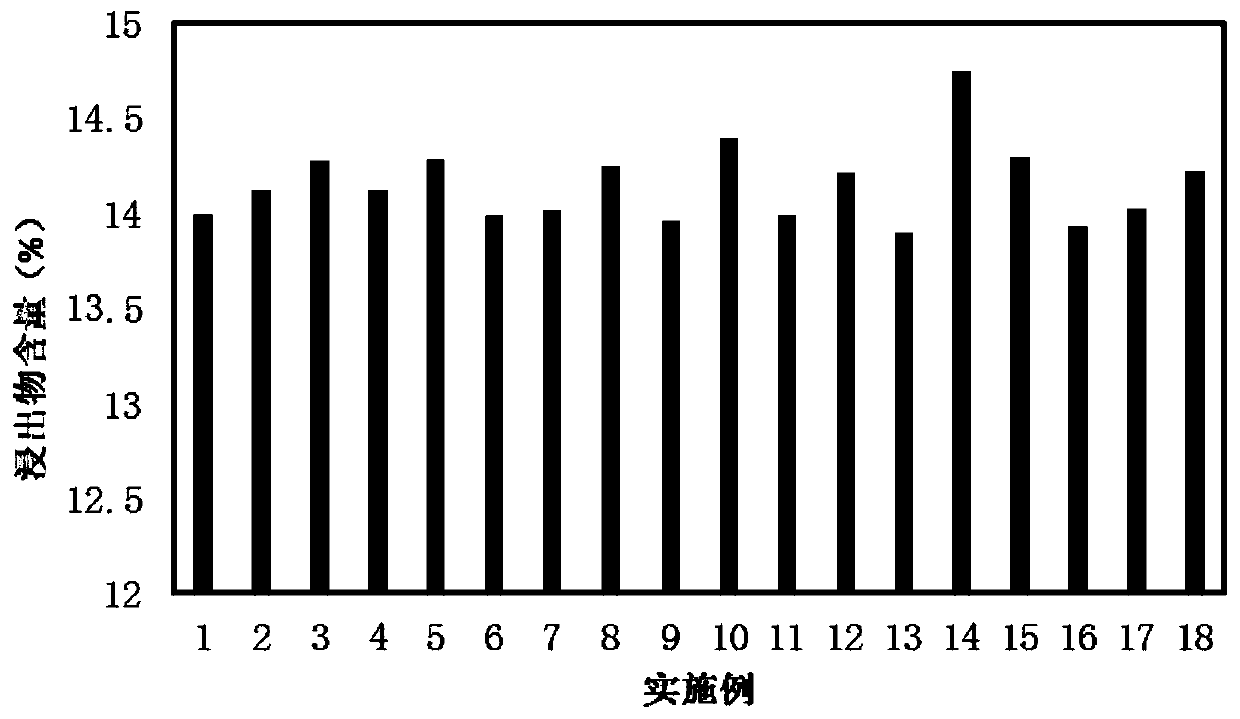

Examples

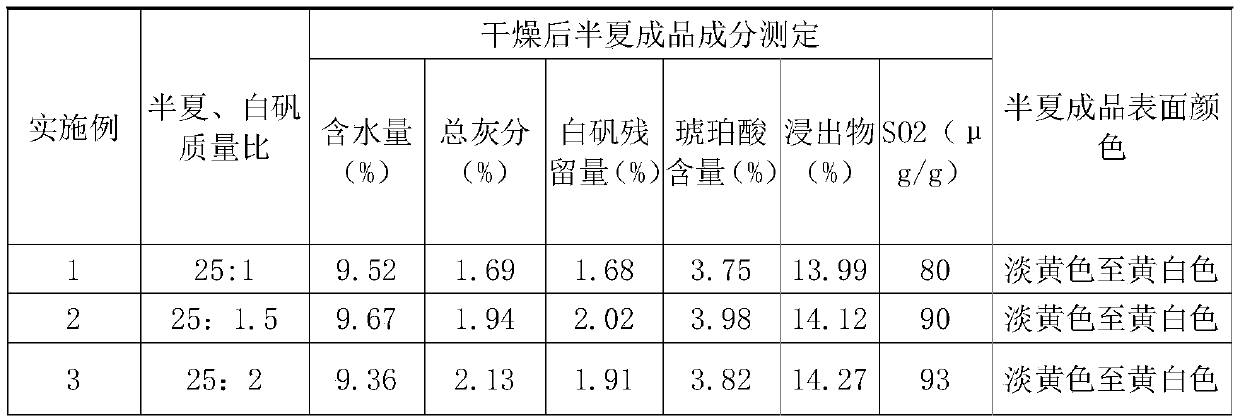

Embodiment 1-3

[0026] (1) Classification: Take the pure pinellia and divide the pinellia into two grades: large and small according to the diameter of the pinellia. The large diameter is not less than 1.0cm and the small diameter is less than 1.0cm;

[0027] (2) Weighing: Weigh pinellia, alum, and water for later use. The mass ratio of pinellia to alum is 25:1;

[0028] (3) Preparation of soaking solution: the concentration of the alum solution is 2%;

[0029] (4) Ultrasonic soaking: Pour the Pinellia and alum solution into an ultrasonic tank, stir evenly, and ultrasonic soak. The ultrasonic frequency is 30KHz, the power is 700W, the ultrasonic temperature is 37℃, and the ultrasonic soaking time is 7h;

[0030] (5) Washing: Take out the soaked Pinellia and rinse with clean water until the pH of the cleaning solution does not change;

[0031] (6) Drying: Pour the washed Pinellia ternata into a baking tray, spread it evenly, and then send it to an oven to dry at 60°C.

[0032] Considering the influence o...

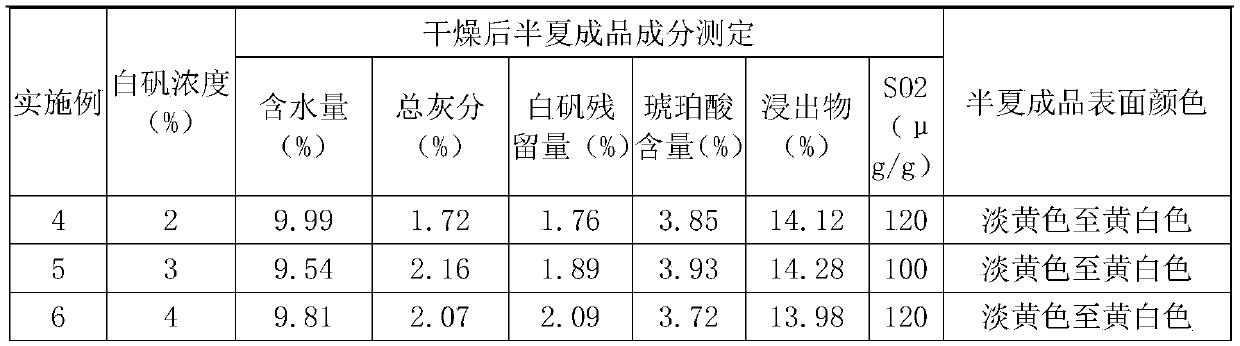

Embodiment 4-6

[0037] (1) Classification: Take the pure pinellia and divide the pinellia into three grades: large, medium and small according to the diameter of the pinellia. The large diameter is not less than 1.0cm and the small diameter is less than 1.0cm;

[0038] (2) Weighing: Weigh pinellia, alum, and water for later use. The mass ratio of pinellia to alum is 25:1.5;

[0039] (3) Preparation of soaking solution: the concentration of the alum solution is 2%;

[0040] (4) Ultrasonic soaking: Pour Pinellia and alum solution into an ultrasonic tank, stir evenly, and ultrasonic soak. The ultrasonic frequency is 25KHz, the power is 650W, the ultrasonic temperature is 35.5℃, and the ultrasonic soaking time is 8h;

[0041] (5) Washing: Take out the soaked Pinellia and rinse with clean water until the pH of the cleaning solution does not change;

[0042] (6) Drying: Pour the washed Pinellia ternata into a baking tray, spread it evenly, and then send it to an oven to dry at 65°C.

[0043] Considering the i...

Embodiment 7-9

[0048] (1) Classification: Take the pure pinellia and divide the pinellia into three grades: large, medium and small according to the diameter of the pinellia. The large diameter is not less than 1.0cm and the small diameter is less than 1.0cm;

[0049] (2) Weighing: Weigh pinellia, alum, and water for later use. The mass ratio of pinellia to alum is 25:2;

[0050] (3) Preparation of soaking solution: the concentration of the alum solution is 3%;

[0051] (4) Ultrasonic soaking: Pour the Pinellia and alum solution into an ultrasonic tank, stir evenly, and ultrasonic soak. The ultrasonic frequency is 25KHz, the power is 650W, the ultrasonic temperature is 37℃, and the ultrasonic soaking time is 7h;

[0052] (5) Washing: Take out the soaked Pinellia and rinse with clean water until the pH of the cleaning solution does not change;

[0053] (6) Drying: Pour the washed Pinellia ternata into a baking tray, spread it evenly, and then send it to an oven to dry at 70°C.

[0054] Considering the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com