Pd-Rh nanocatalyst, and preparation method and application thereof

A nano-catalyst and solvent technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems such as low product selectivity, and achieve the double bond hydrogenation selection of m-nitrostyrene High performance, stable catalytic performance and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of Pd-Rh nano catalyst, comprising:

[0022] Palladium source solution, rhodium source solution, aqueous solution of potassium iodide and polyvinylpyrrolidone are mixed and dissolved in a solvent to obtain a mixture, the mixture is heated, cooled, centrifuged, and cleaned to obtain a Pd-Rh nanocatalyst; the palladium source is sodium chloropalladate ; The rhodium source is sodium hexachlororhodate.

[0023] In the invention, the palladium source solution, rhodium source solution, potassium iodide aqueous solution and polyvinylpyrrolidone are mixed and dissolved in the solvent.

[0024] According to the present invention, the palladium source is preferably sodium chloropalladate; the rhodium source is preferably sodium hexachlororhodate. The present invention does not limit the source, and it can be commercially available.

[0025] Wherein, the concentration of the sodium chloropalladate solution is preferably 19.5mM~...

Embodiment 1

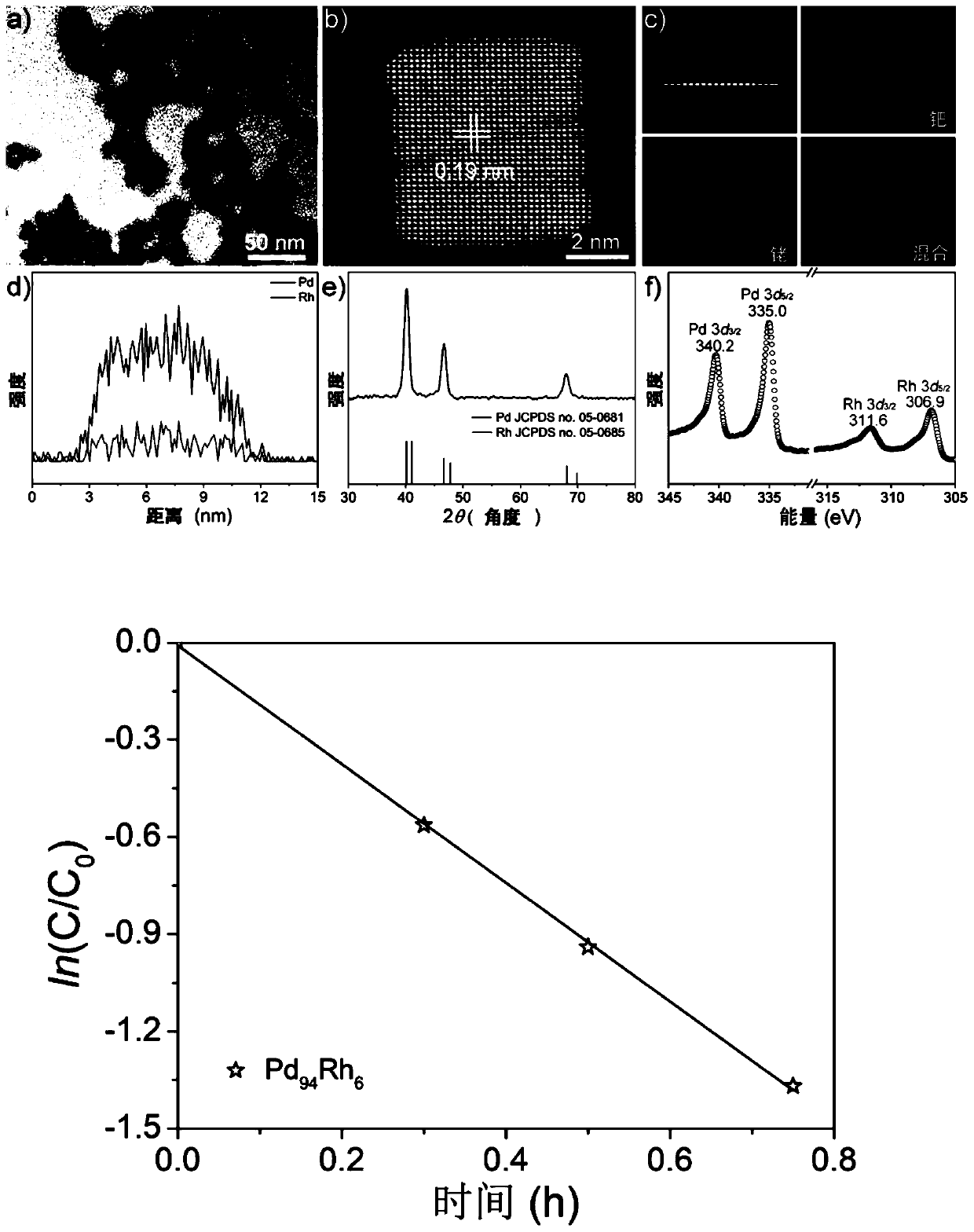

[0047] A Pd-Rh nanometer catalyst comprises Pd-Rh nanocrystals in which rhodium is doped in palladium crystals.

[0048] The preparation method of above-mentioned Pd-Rh nanometer catalyst comprises:

[0049] 1.7ml of 20mM sodium chloropalladate aqueous solution, 0.3ml of 20mM sodium hexachlororhodium aqueous solution, 1ml of 1M potassium iodide aqueous solution and 150mg of polyvinylpyrrolidone were mixed in 10ml of dimethylformamide, and the homogeneous mixture was placed in 140 Heating in an oven at ℃ for 4 hours, cooling, centrifuging at a speed of 10000 rpm, washing with water three times, and then washing with ethanol three times, then placing it in a UV-ozone cleaning machine at a distance of 5 mm from the lamp for 30 minutes, taking it out to obtain the Pd-Rh nanocatalyst.

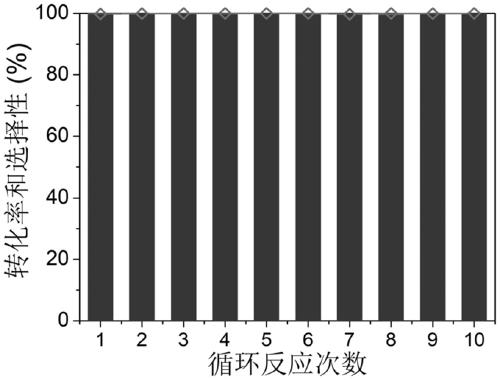

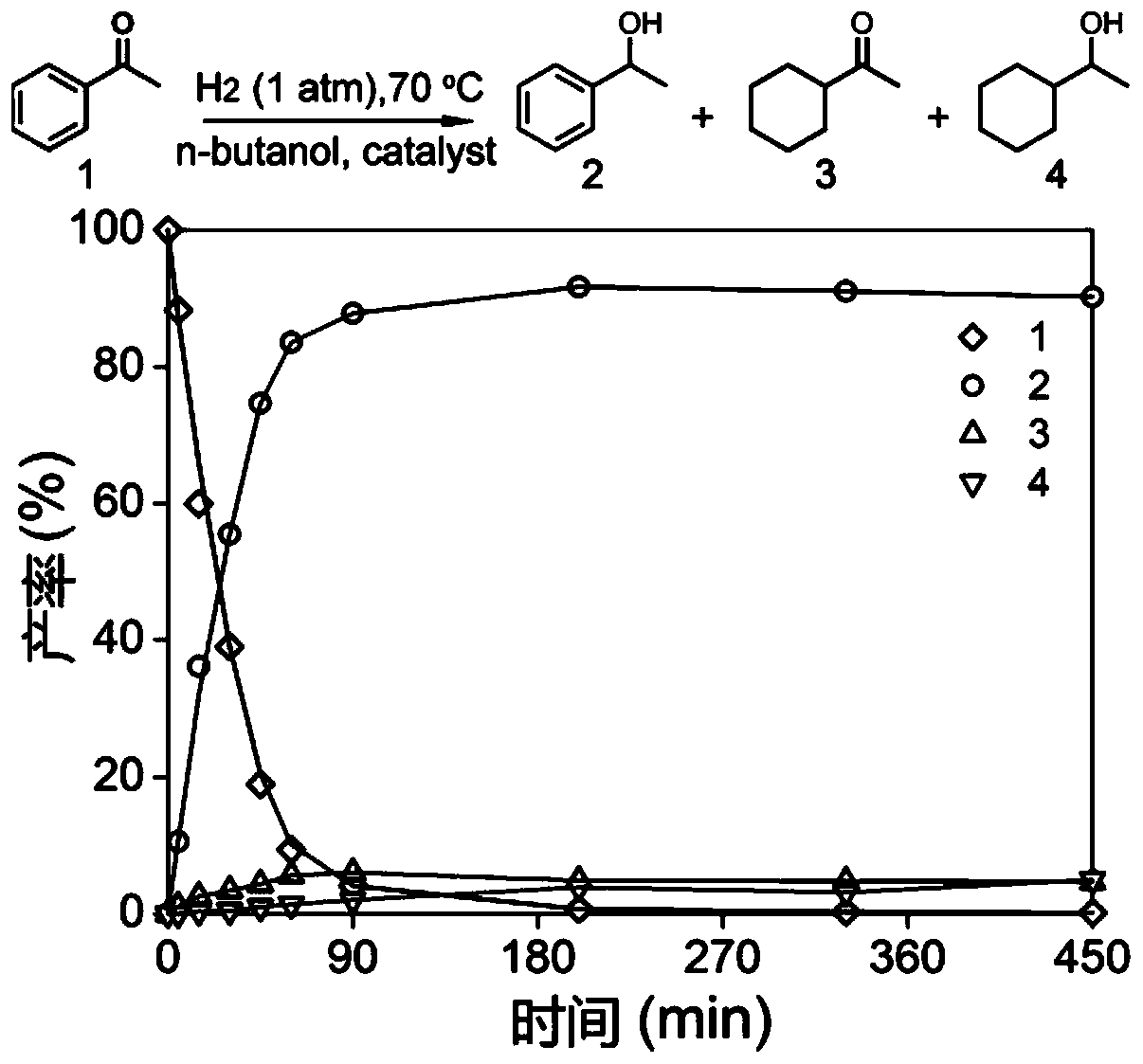

[0050] Adopt the Pd-Rh nanometer catalyst that embodiment 1 makes to carry out the catalytic performance test of nitrostyrene selective hydrogenation reaction:

[0051] In the catalytic test, we a...

Embodiment 2

[0054] A Pd-Rh nanometer catalyst comprises Pd-Rh nanocrystals in which rhodium is doped in palladium crystals.

[0055] The preparation method of above-mentioned Pd-Rh nanometer catalyst comprises:

[0056] 1.7ml of 20mM sodium chloropalladate aqueous solution, 0.3ml of 20mM sodium hexachlororhodium aqueous solution, 1ml of 1M potassium iodide aqueous solution and 130mg of polyvinylpyrrolidone were mixed in 10ml of dimethylformamide, and the homogeneous mixture was placed in 140 Heating in an oven at ℃ for 4 hours, cooling, centrifuging at a speed of 10000 rpm, washing with water three times, and then washing with ethanol three times, then placing it in a UV-ozone cleaning machine at a distance of 5 mm from the lamp for 30 minutes, taking it out to obtain the Pd-Rh nanocatalyst.

[0057] Adopt the Pd-Rh nanometer catalyst that embodiment 2 makes to carry out the catalytic performance test of nitrostyrene selective hydrogenation reaction:

[0058] In the catalytic test, we a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com