Producing and processing system for silicon metal powder

A processing system and metal silicon powder technology, which is applied in the production and processing system of metal silicon powder and the preparation system of metal silicon, can solve the problems of users' economic loss, yield discount, and difference in crushing effect, so as to improve the yield and avoid waste , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

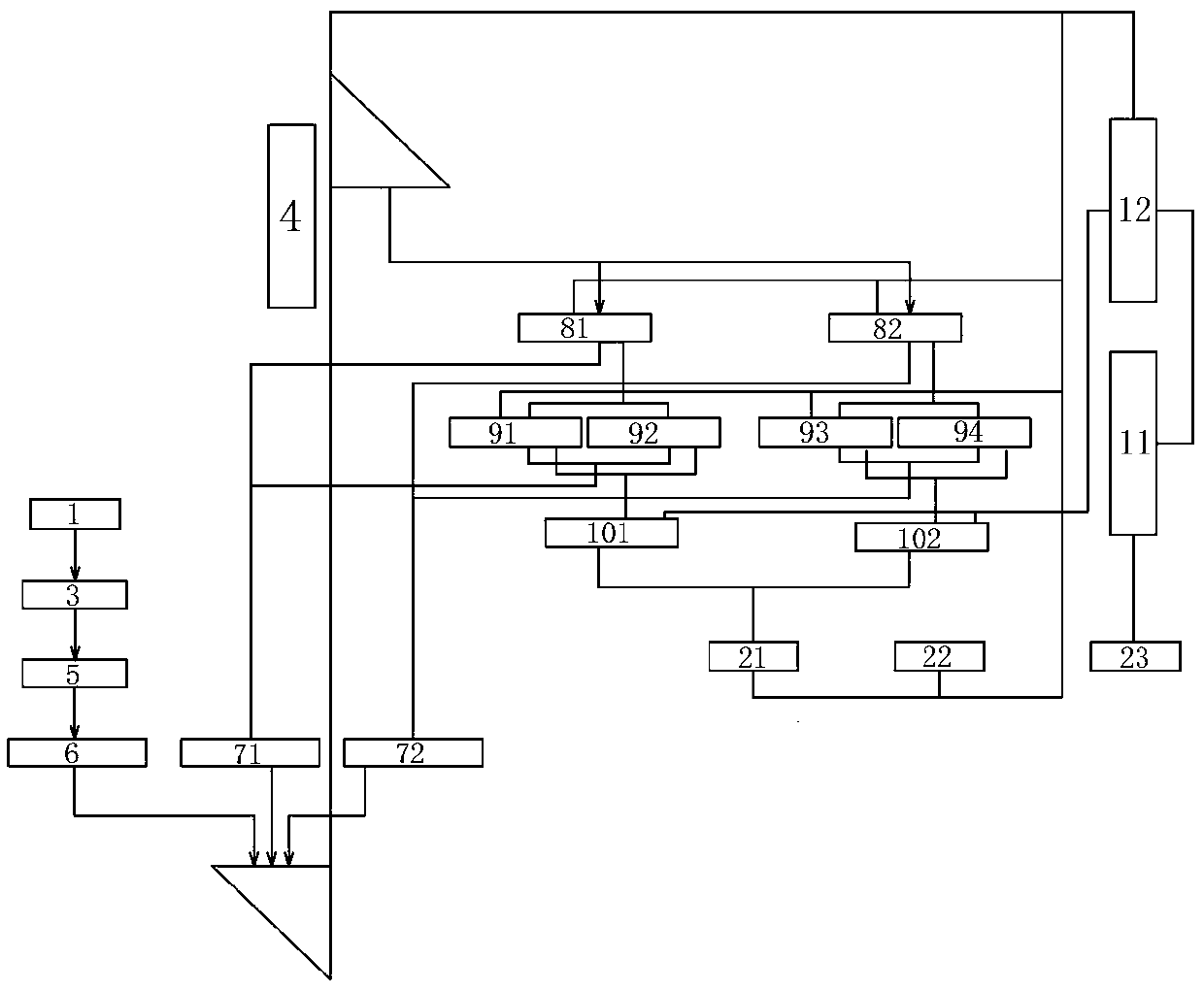

[0017] Embodiment: A metal silicon powder production and processing system, including a storage device, a conveying device, a crushing system, a screening system and a dust removal system, the storage device includes a raw material silo 1 and a product silo 2, and the conveying device includes a vibrating feeder 3 And bucket elevator 4, the crushing system is composed of jaw crusher 5, coarse hammer crusher 6 and fine hammer crusher 7 three-stage crushing device, and the screening system is composed of linear coarse screen 8 and linear fine screen 9 It is composed of a round fine screen 10 and a three-stage screening device. The dust removal system is composed of a pulse dust collector 11 connected to a cyclone separator 12, pipelines and power supply devices.

[0018] The raw material silo 1 is connected to the jaw crusher 5 and the coarse hammer crusher 6 in turn through the vibrating feeder 3, and the discharge port of the coarse hammer crusher 6 is connected to the three-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com