Microwave deoiling recovery device for oil-containing articles and application method thereof

An oil recovery and microwave technology, applied in separation methods, chemical instruments and methods, petroleum industry, etc., can solve the problems of contamination, having to be scrapped, not having technical ability, not clearly mentioned, etc., so that the oil removal process can be realized in real time. Visual, improve work efficiency, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

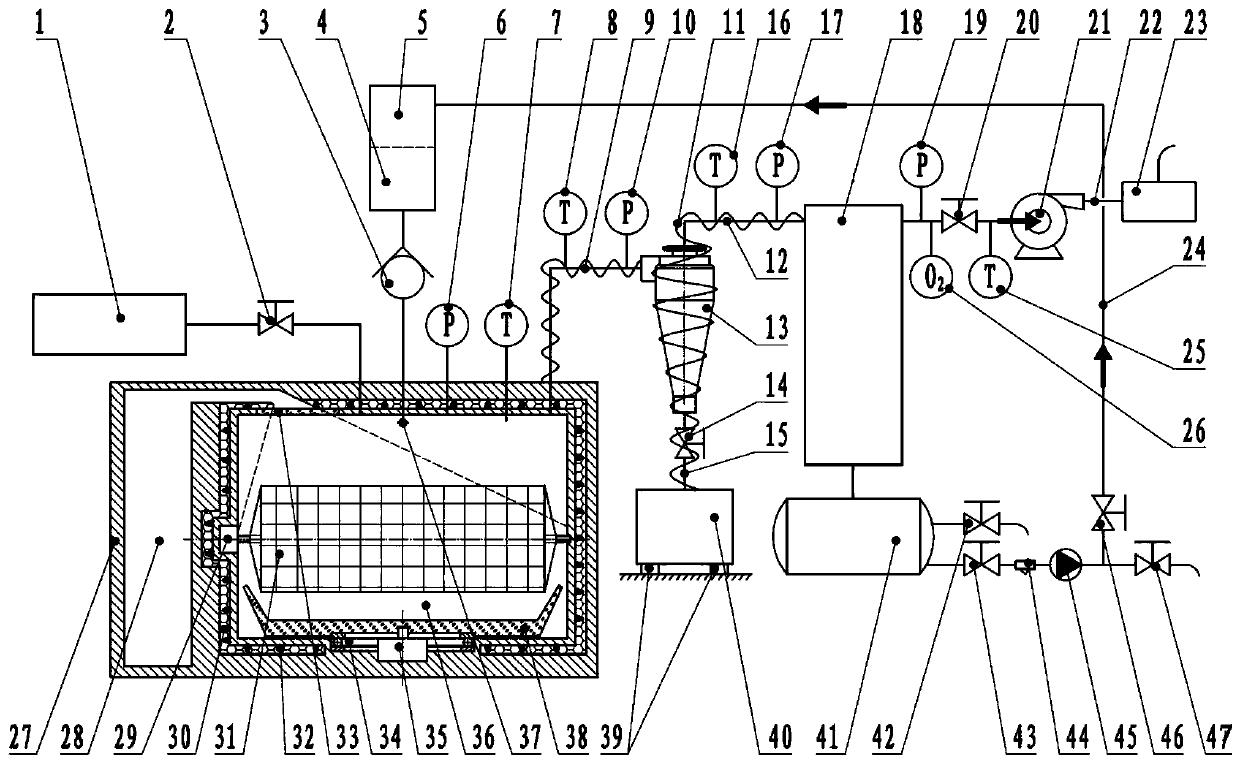

[0040] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, a microwave oil removal recovery device for oily articles, comprising

[0041] Microwave processor 27, microwave processor 27 is provided with heating chamber 36 and microwave generator 28, the top of heating chamber 36 has microwave inlet, the microwave outlet of microwave generator 28 communicates with the microwave inlet of heating chamber 36 tops;

[0042] Vacuum pump 1, the vacuum pump 1 communicates with the heating chamber 36 through a pipeline, and the first valve 2 is connected to the pipeline;

[0043] Water spray sprayer 4, water spray sprayer 4 communicates with heating chamber 36 by water spray pipeline, and check valve 3 is connected on the water spray pipeline, is provided with water storage chamber 5 and water spray nozzle in the water spray sprayer 4, water spray spray The mouth is communicated with the heating chamber 36 through the water spray pipeline;

...

Embodiment 2

[0052] Compared with Embodiment 1, this embodiment is different in that: the fourth valve 42 is connected to the external delivery pipeline of the fuel tank, and the fifth valve 43, filter 44, and centrifugal pump 45 are sequentially connected to the external delivery pipeline of the water tank. And the seventh valve 47 , the water tank output pipeline between the centrifugal pump 45 and the seventh valve 47 is connected with the water circulation pipeline 24 , and the water circulation pipeline 24 is connected with the sixth valve 46 .

[0053] In actual use: the fourth valve 42 is used to control the opening and closing of the external pipeline of the fuel tank, the fifth valve 43 is used to control the opening and closing of the external pipeline of the water tank, the filter 44 is used to filter the waste water from the external pipeline of the water tank, and the centrifugal pump 45 is used to pump the filtered water into the water circulation pipeline 24 and then into the...

Embodiment 3

[0055] Compared with Embodiment 1, the difference of this embodiment is that the microwave processor 27 includes at least an outer casing and a convenient door that can be opened and closed with the outer casing, and the convenient door and the heating compartment 36 form a closed cavity , the heating bin 36 includes an inner shell, the inner shell of the heating bin 36 is made of metal, and the outer shell of the inner shell of the heating bin 36 is provided with a microwave generator 28, and the inner shell of the heating bin 36 is composed of An electric heating belt 32 and a thermal insulation layer 30 are provided in sequence from the inside to the outside.

[0056] Preferably, the middle part of the heating chamber 36 is provided with corresponding circular grooves on the opposite side walls, and the hollow cylinder 31 is detachably connected to the circular grooves on the two side walls, and one of the side walls is circular. The groove is also provided with a first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com