Device for removing oil on surface of barrel cover of soft barrel of medical waste liquid collecting barrel

A waste liquid collection and barrel cover technology, which is applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of high labor intensity, high labor cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

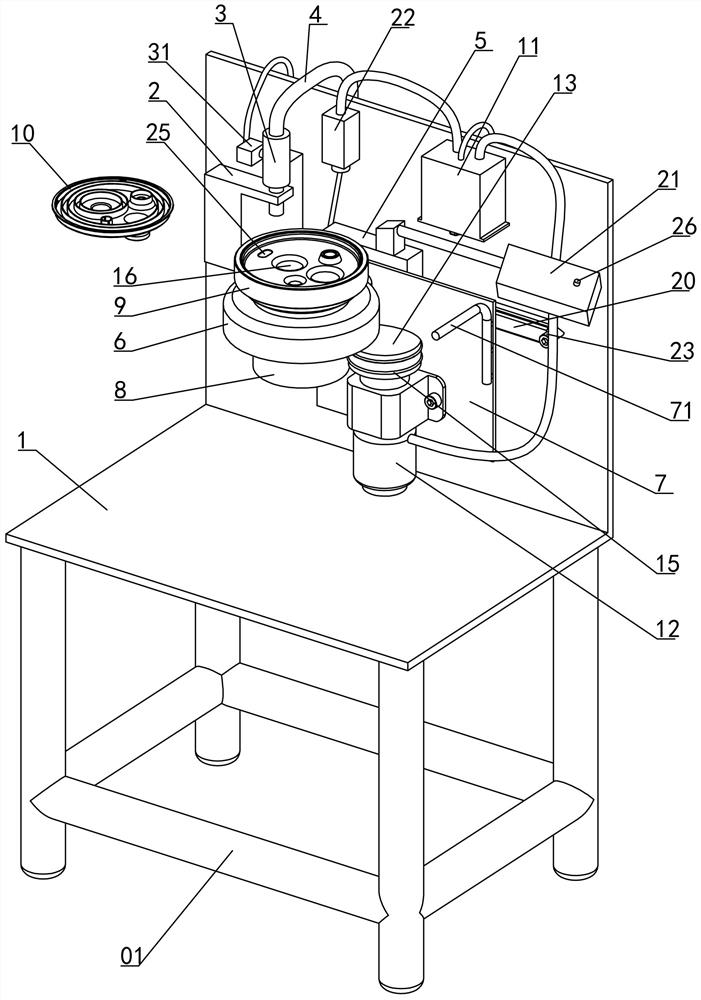

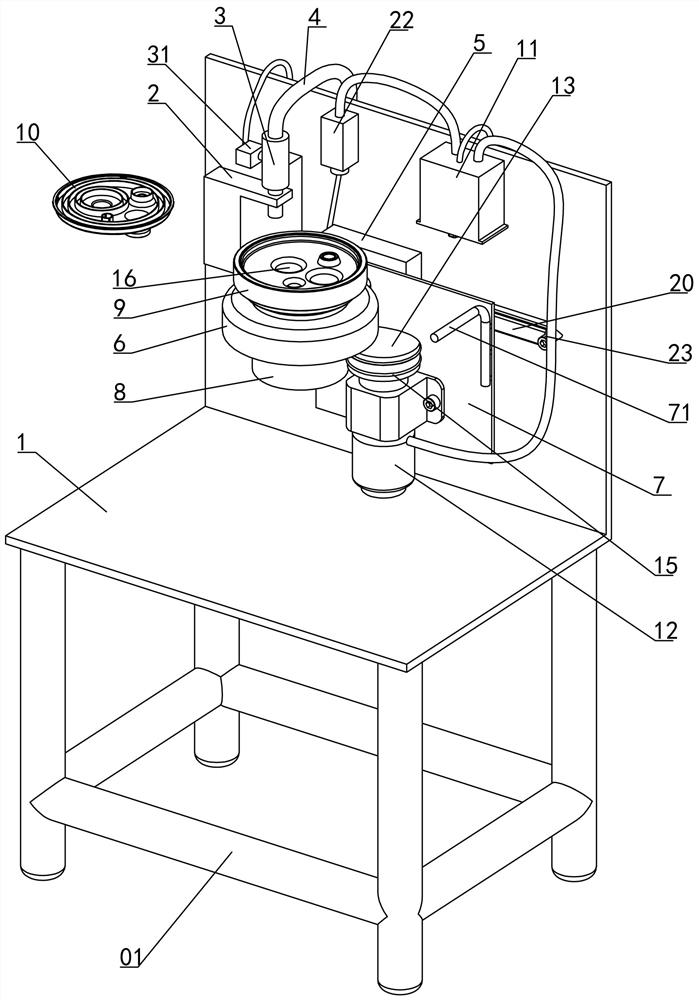

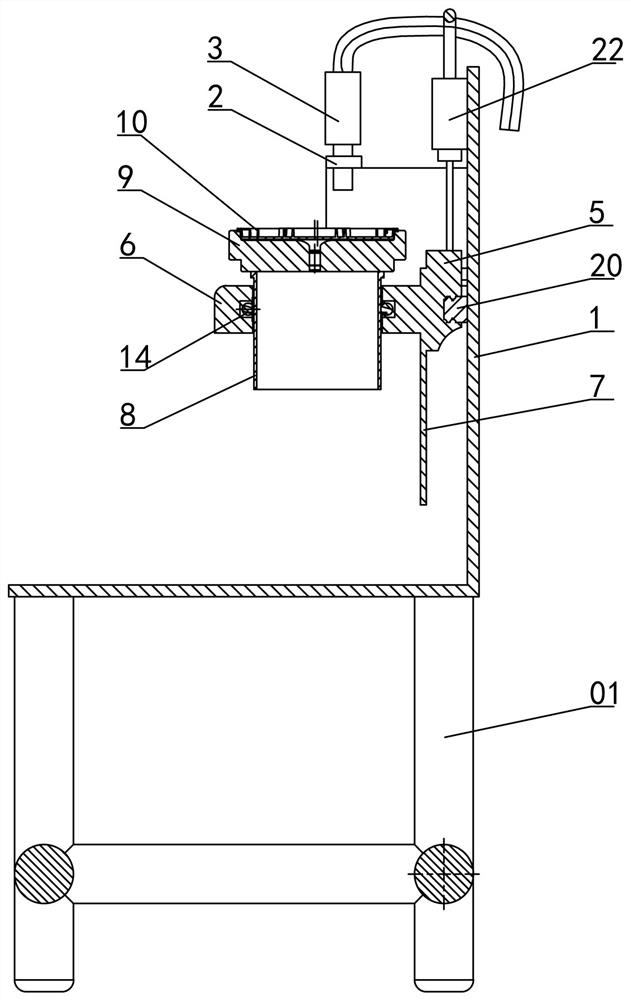

[0010] The invention relates to a device for degreasing the surface of a soft barrel cover of a medical waste liquid collection barrel, such as figure 1 — image 3 As shown, it includes a bracket 1, on which a spraying fire assembly and a rotating assembly are arranged, and the fire spraying assembly includes a nozzle fixing block 2 arranged on the bracket 1, a nozzle 3 is arranged on the nozzle fixing block, and a solenoid valve 31 is arranged on the nozzle 3, The spray head 3 is connected to the liquefied gas source through the pipeline 4. The rotating assembly includes a push mechanism and a travel switch 22 set on the bracket 1. A rotating mechanism is arranged on the pushing mechanism. The rotating mechanism includes a rotating fixed seat 5 and a rotating fixed seat. 5 is provided with a rotating bracket 6 and a support plate 7, a rotating sleeve 8 is arranged in the rotating bracket 6, a bung lid holder 9 is arranged on the rotation sleeve, a bung lid 10 is placed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com