A high-performance water-based adhesive composition for artificial turf and its preparation method

A technology of water-based adhesives and artificial turf, applied in the direction of adhesives, adhesive additives, carboxyl rubber adhesives, etc., can solve the problems of degumming and bonding strength drop, failure to achieve, and limited improvement, etc., to achieve excellent coverage effect, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation method of test sample:

[0027] (1) Tuft the twisted artificial turf on the base fabric with a specified line spacing and needle spacing with a tufting machine to form a semi-finished artificial turf;

[0028] (2) The water-based adhesive composition prepared by the embodiment and the comparative example according to 1.2kg / m 2 The amount is painted on the bottom and back of the semi-finished lawn, and the test sample is obtained by curing in an oven.

[0029] Sample performance test method:

[0030] Initial pull-out force:

[0031] Use an electronic universal material testing machine to test according to the method in the standard ISO4919, specifically to intercept a newly prepared sample block of 20cm*20cm, and place it at a relative humidity of (65±4)% and a temperature of (20± 2) Under the environment of ℃ for 24 hours, put the sample block to be tested on the electronic universal material testing machine and clamp half a tuft of grass silk with clamps...

Embodiment 1

[0037] The preparation method of high-performance water-based adhesive composition for artificial turf, the steps are as follows:

[0038] (1) Add 100g of calcium carbonate and 2.5g of itaconic acid into a high-efficiency mixer, set the temperature to 100°C, turn on the stirring shaft, and discharge after 20 minutes of reaction to obtain modified calcium carbonate for later use;

[0039] (2) The emulsifier compounded by the deionized water of 500g, the potassium persulfate initiator of 0.5g, the sodium lauryl sulfate of 1.2g and the acrylamide sodium stearate of 2.8g and the acrylic acid polymerization monomer of 25g Put it into the reaction kettle, replace the air in the reaction kettle with nitrogen and evacuate it, press ethylene into the reaction kettle and pressurize it to 15MPa, turn on the stirring device and heat it to 60°C to react, and add ethylene to stabilize the pressure as the reaction progresses After reacting for 5 hours, an ethylene acrylic acid emulsion was o...

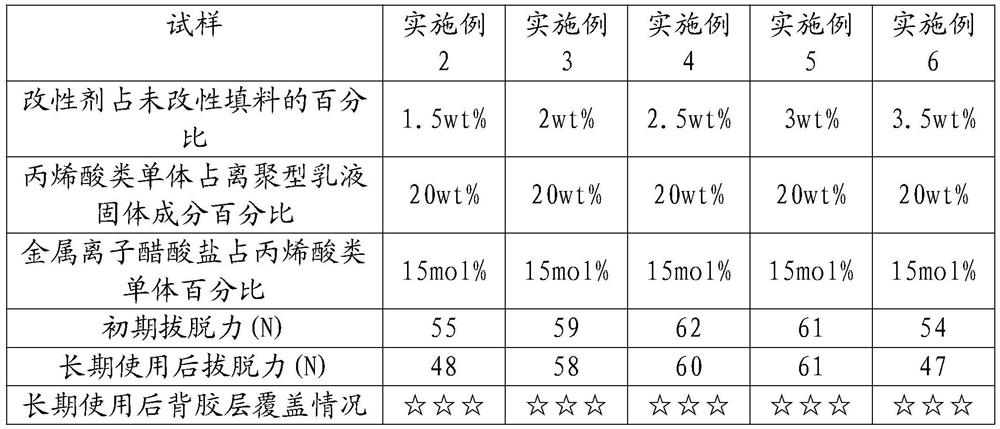

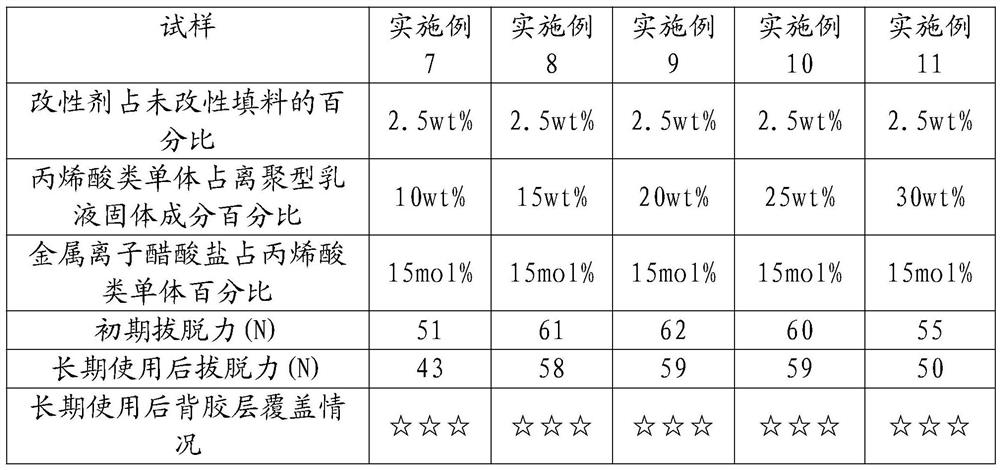

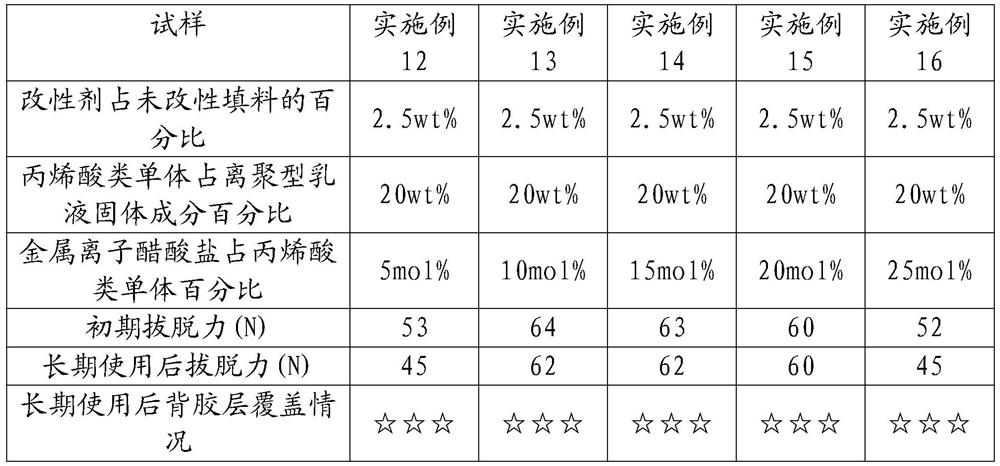

Embodiment 2

[0052] The preparation method of high-performance water-based adhesive composition for artificial turf, the steps are as follows:

[0053] (1) Add 100g of calcium carbonate and 1.5g of succinic acid into the high-efficiency mixer, set the temperature to 100°C, turn on the stirring shaft, and discharge after 20 minutes of reaction to obtain modified calcium carbonate for later use;

[0054] (2) The deionized water of 500g, the potassium persulfate initiator of 0.5g, the emulsifier compounded by 1.2g sodium lauryl sulfate and 2.8g acrylamide sodium stearate and the methacrylic acid polymerization monomer of 25g Put it into the reaction kettle, replace the air in the reaction kettle with nitrogen and evacuate it, press ethylene into the reaction kettle to pressurize to 15Mpa, turn on the stirring device and heat it to 60°C for reaction, and add ethylene to stabilize the pressure as the reaction progresses , after reacting for 5 hours to obtain an ethylene methacrylic acid emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com