Manufacturing method of GOI test sample wafer for improving breakdown characteristic of trench gate

A manufacturing method and technology of breakdown characteristics, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as electric field concentrated breakdown, test result interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

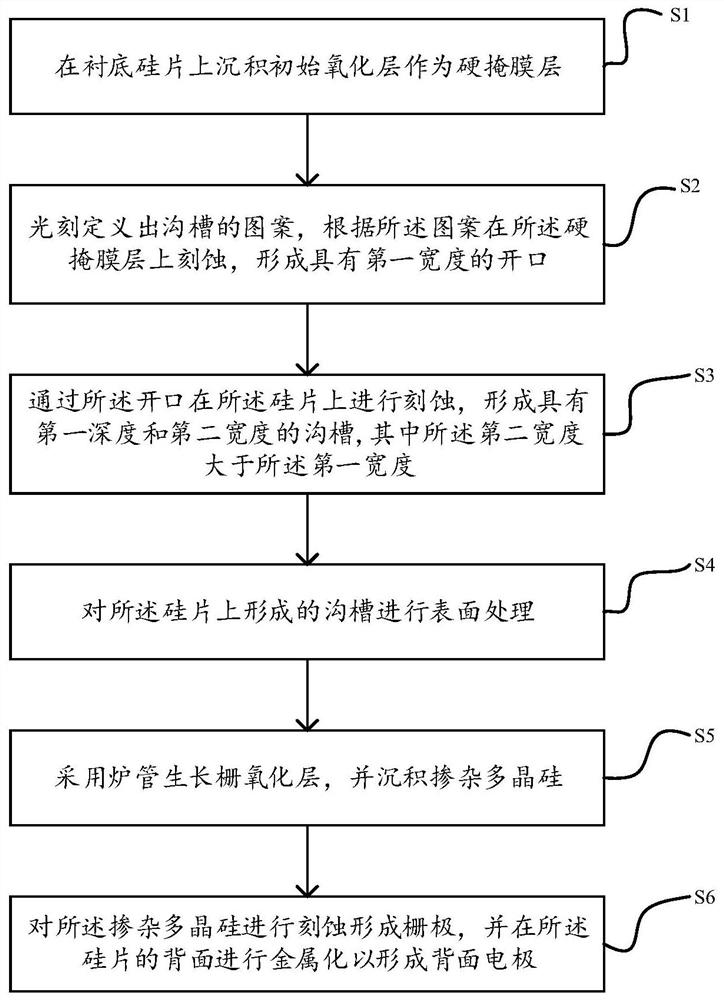

[0031] see figure 1 , the present embodiment proposes a method for manufacturing a GOI test sample to improve the breakdown characteristics of the trench gate, which specifically includes the following steps:

[0032] S1: An initial oxide layer is deposited on the substrate silicon wafer as a hard mask layer.

[0033] The substrate silicon wafer in the present invention can be an N-type substrate or a P-type substrate, and in this embodiment, it is preferably an N-type substrate.

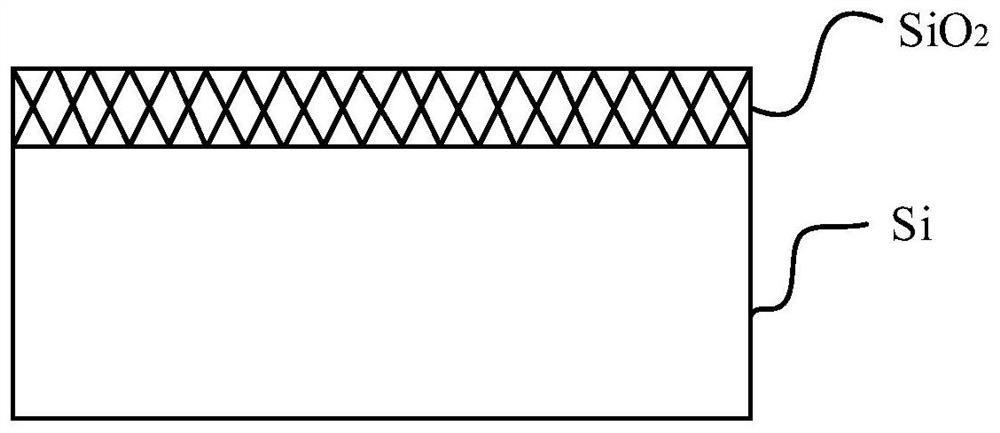

[0034] The initial oxide layer in the present invention is insulating material SiO 2 , used to protect the internal substrate silicon wafer and realize the surface insulation function, the substrate silicon wafer is Si, such as figure 2 shown.

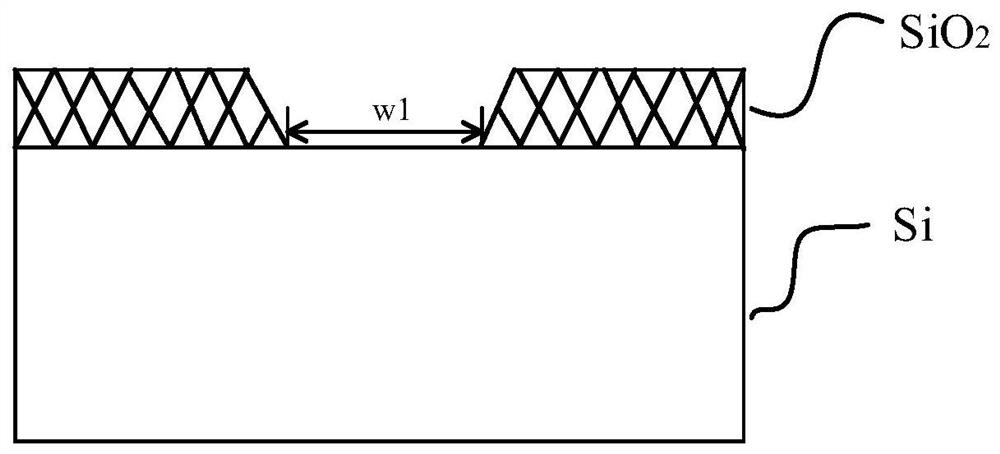

[0035] The method for depositing the initial oxide layer in the present invention is not limited to oxidation methods such as wet oxygen, dry oxygen, and chlorine-doped oxidation. In order to reduce the front oxidation rate, the thickness of the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com