Heat treatment method of Fe-Mn-Al-C austenitic low-density steel

A heat treatment method and technology for low-density steel, applied in the field of heat treatment of iron-manganese-aluminum-carbon austenitic low-density steel, can solve problems such as the influence of the safety of steel use and the reduction of work hardening ability, so as to improve the safety of use and yield. The effect of strength improvement and yield strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Fe-30Mn-11Al-1.2C austenitic low-density steel after solution treatment at 1100°C for 1 h was used. The steel is subjected to traditional 450°C / 1h aging treatment, room temperature and air cooling.

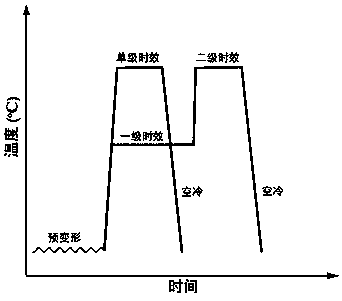

[0032] (1) According to figure 1 In the deformation heat treatment process shown, the aged steel is pre-stretched and deformed, and the tensile strain rate is 10 -3 ·s -1 , the total strain is 20%.

[0033] (2) After the steel stretched in (1) is subjected to a single-stage aging treatment at 600°C / 10min, it is air-cooled at room temperature.

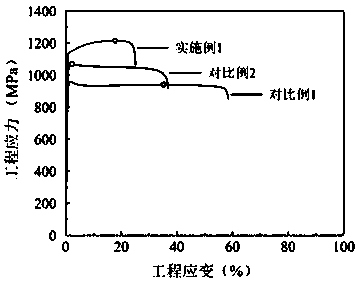

[0034] The low-density steel that this example obtains is carried out room temperature mechanical property test, and the result is as follows figure 2 As shown in Table 1, the yield strength is 1125MPa, the tensile strength is 1214MPa, the uniform elongation is 17.8%, and the total elongation is 25.0%.

[0035] From comparative examples 1 and 2 and embodiment 1, it can be seen that comparative example 1 adopts the traditional a...

Embodiment 2

[0039] Fe-30Mn-11Al-1.2C austenitic low-density steel after solution treatment at 1100°C for 1 h was used.

[0040] (1) According to figure 1 In the deformation heat treatment process shown, the steel is subjected to pre-rolling deformation, the deformation amount of each pass is 5%, and the total deformation amount is 20%.

[0041] (2) The pre-rolled steel is subjected to bipolar aging treatment. First, the steel is subjected to primary aging treatment at 450°C / 1h, and then rapidly (15°C / min) is heated to a secondary aging temperature of 600°C, and secondary aging treatment is performed at 600°C / 30min.

[0042] The low-density steel obtained in this example was tested for mechanical properties at room temperature. The results are shown in Table 1. The yield strength is 1206MPa, the tensile strength is 1300MPa, the uniform elongation is 18.2%, and the total elongation is 33.4%.

Embodiment 3

[0044] Fe-30Mn-11Al-1.2C austenitic low-density steel after solution treatment at 1100°C for 1 h was used.

[0045] (1) According to figure 1 In the deformation heat treatment process shown, the steel is subjected to pre-rolling deformation, the deformation amount of each pass is 5%, and the total deformation amount is 20%.

[0046] (2) The pre-rolled steel is subjected to unipolar aging treatment. The pre-rolled steel was subjected to a single-stage aging treatment at 600°C / 40min, and air-cooled at room temperature.

[0047] The low-density steel obtained in this example was tested for mechanical properties at room temperature, and the results are shown in Table 1. The yield strength is 1154MPa, the tensile strength is 1268MPa, the uniform elongation is 17.9%, and the total elongation is 31.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com