A kind of electrothermochromic fiber, its preparation method and application

A thermochromic and chromogenic technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of slow production speed, complicated preparation process, high cost, etc., and achieve high production efficiency and wide selection range , the effect of diversification of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

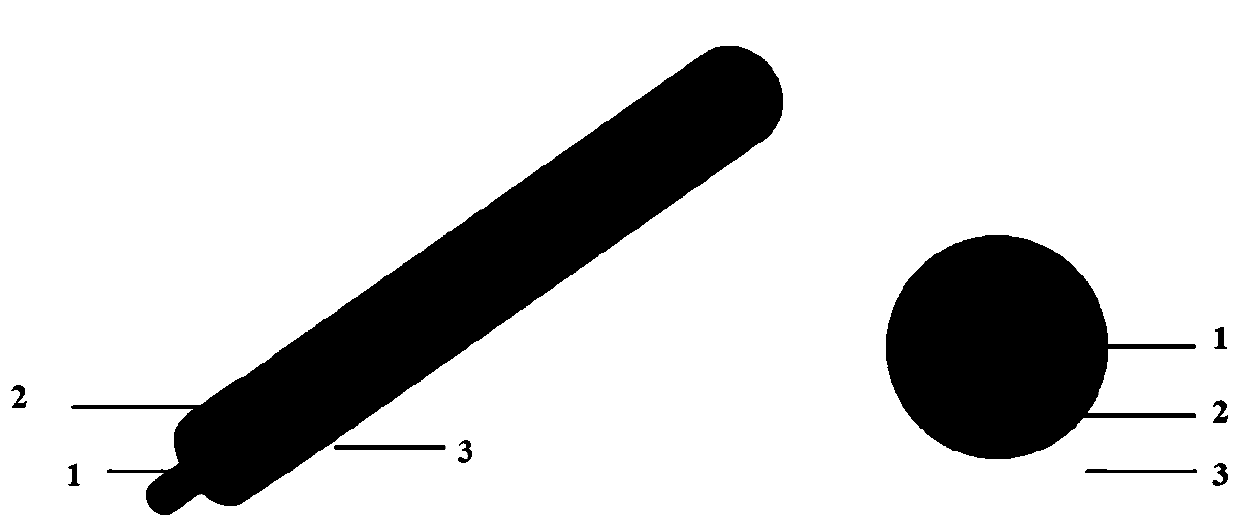

[0053] The invention provides a method for preparing an electrothermochromic fiber. The electrothermochromic fiber includes a composite material with a three-layer structure, which is a cladding layer, an intermediate layer and a core layer in sequence from the outside to the inside, wherein the cladding layer is a protective layer. layer, the middle layer is a thermochromic layer, and the core layer is a conductive layer;

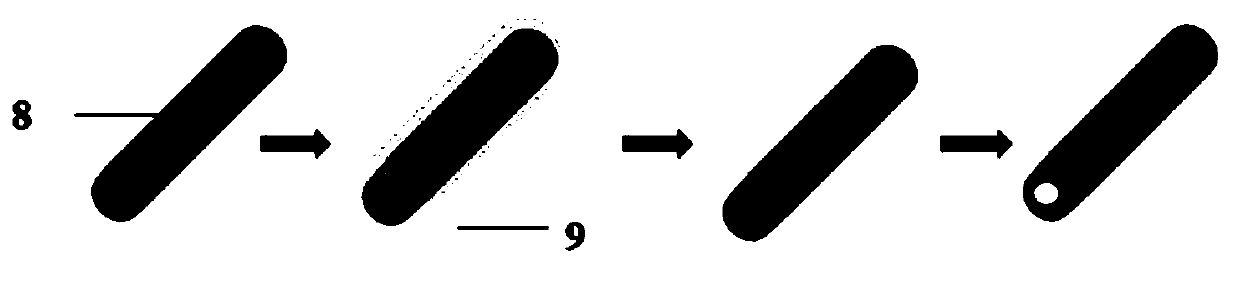

[0054] The thermochromic layer is prepared by adopting the thermosoftening wire drawing method, specifically:

[0055] Obtaining the preform of the thermochromic layer first, and then performing thermosoftening drawing on the preform to obtain the fibers of the thermochromic layer;

[0056] The preform rod of the thermochromic layer contains a hole structure, the material of the conductive layer passes through the hole of the preform rod, and the thermochromic layer is obtained by using the thermosoftening wire drawing method, and the A conductive layer i...

Embodiment 1

[0143] In this embodiment, a coaxial electrothermochromic fiber is firstly provided, which has certain stability, electrical conductivity, friction resistance and color fastness to washing, is suitable for wearing, and has a thermochromic temperature of 31°C.

[0144] Among them, the electrothermochromic fiber electrode material is 304 stainless steel filaments with a diameter of 10 μm, the material of the color-changing layer is a composite material of thermochromic microcapsules and polymethyl methacrylate, the thickness of the color-changing layer is 50 μm, and the cladding material is Polymethyl methacrylate, 50 μm thick.

[0145] The embodiment of the present invention also provides an electrothermochromic fiber method including: preparation of a thermochromic composite material, preparation of a prefabricated rod with a central hole, and thermal drawing of the fiber.

[0146] The preparation method of thermochromic material comprises the following steps: (1) take by weig...

Embodiment 2

[0155]In the embodiment of the present invention, an electrothermochromic fiber with a square structure is provided, which has certain stability, electrical conductivity, friction resistance and color fastness to washing, is suitable for wearing, and has a thermochromic temperature of 31°C.

[0156] Among them, the electrothermochromic fiber electrode material is 304 stainless steel filaments with a diameter of 10 μm, the material of the color-changing layer is a composite material of thermochromic microcapsules and polymethyl methacrylate, the thickness of the color-changing layer is about 50 μm, and the cladding material It is polymethyl methacrylate with a thickness of about 50 μm.

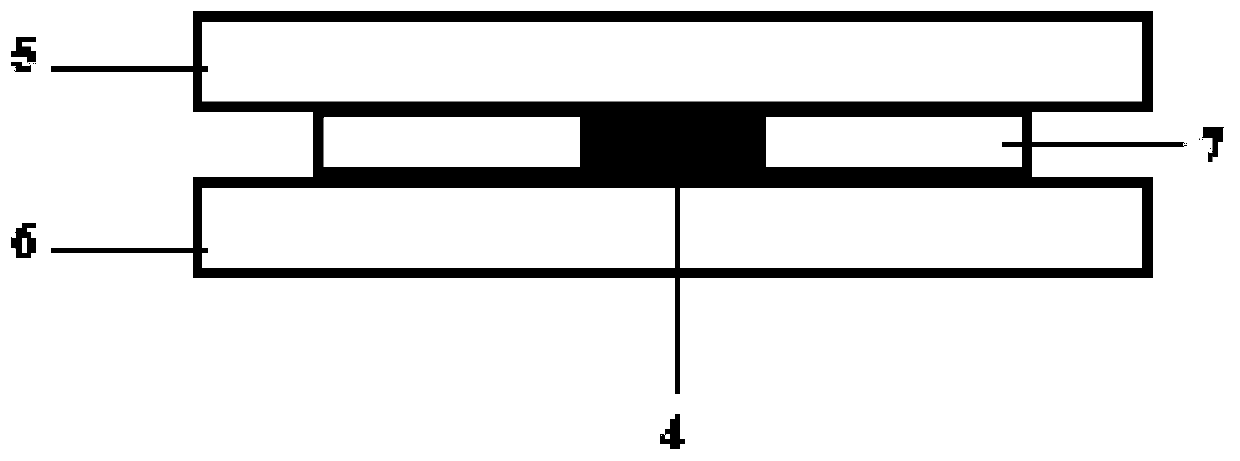

[0157] The preparation of the central hole preform includes the following steps (film winding method): (1) filling the thermochromic composite material particles into figure 2 In the mold shown, the mold is a square groove of (length×width×height) 180mm×10mm×10mm, put the mold between the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com