Artificial Simulation Method of Impact Damage of Composite Honeycomb Sandwich Structure

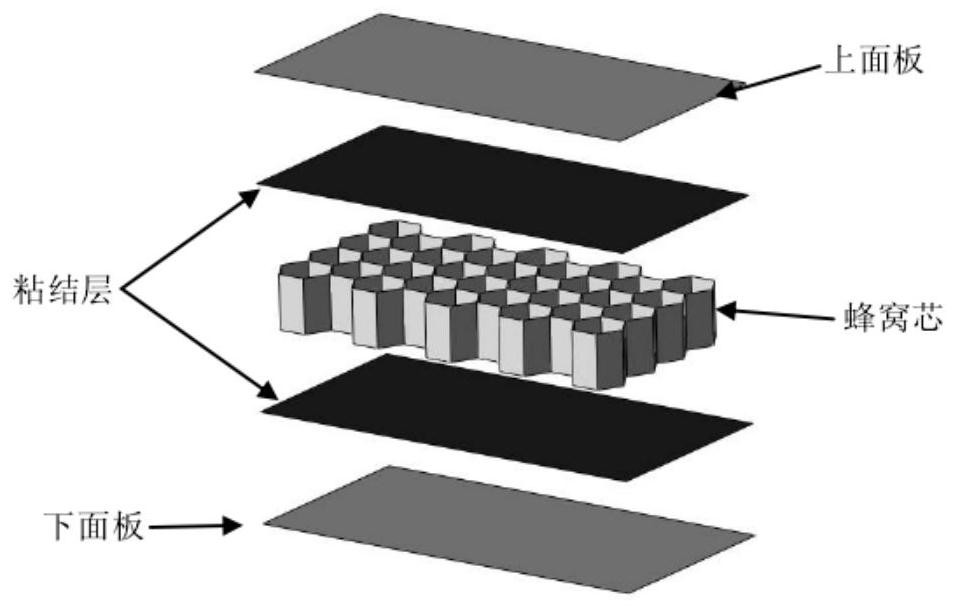

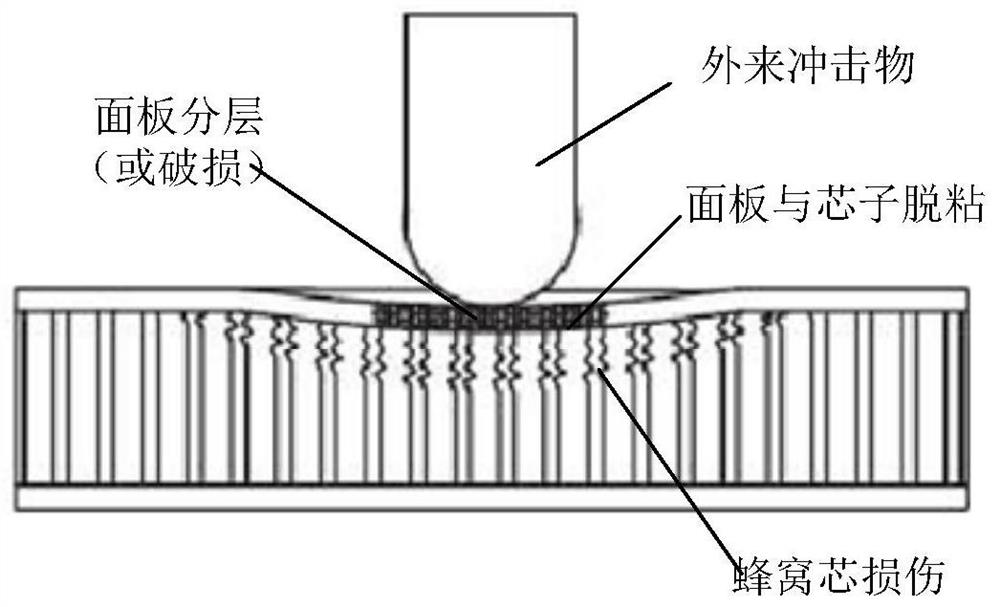

A technology of honeycomb sandwich structure and impact damage, which is applied to the artificial simulation of impact damage of composite honeycomb sandwich structure and the field of artificial simulation of core damage in honeycomb structure, which can solve the problems of ineffective simulation of honeycomb core damage, etc. Conducive to the correct assessment of structural strength, conducive to the effect of reasonable repair decisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The artificial simulation method of impact damage of composite honeycomb sandwich structure, its specific implementation process is as follows:

[0041] 1) Fabricate the honeycomb core prefabricated part: select a suitable honeycomb core according to the design requirements and cut it to the required size to form the honeycomb core prefabricated part 1 .

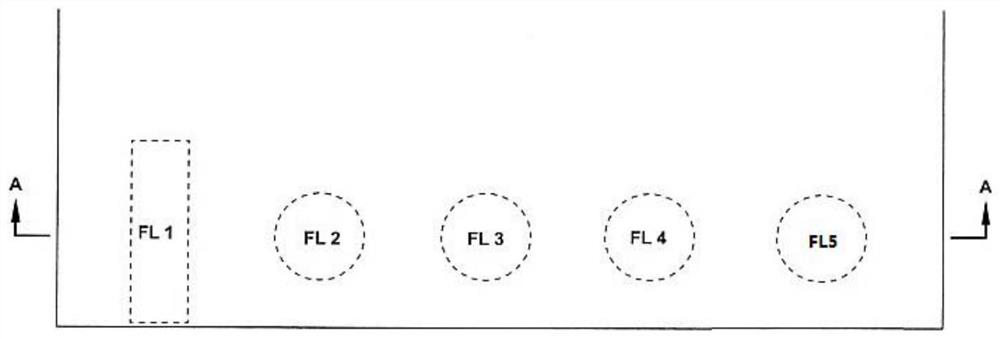

[0042] 2) Simulation calculation and analysis: According to the actual physical parameter characteristics and related mechanical performance data of the honeycomb core prefabricated part 1, the finite element model of the honeycomb core prefabricated part is established, and the local area of the honeycomb core prefabricated part is uniformly distributed through the finite element analysis software. The static pressure load is simulated and calculated (the size of the area where the load is applied depends on the desired damage size), and the compression displacement value of the honeycomb core just entering the unst...

Embodiment 2

[0049] 1) Making a honeycomb prefabricated part: select a suitable honeycomb core according to the design requirements and cut it to the required size to form a honeycomb core prefabricated part 1 .

[0050] 2) Simulation calculation and analysis: According to the actual physical parameter characteristics and related mechanical performance data of the honeycomb core prefabrication 1, the finite element analysis model of the honeycomb core prefabrication is established, and the free fall impact simulation of the honeycomb prefabrication is carried out through the finite element analysis software Calculate (the diameter of the spherical punch depends on the desired damage size), and obtain the impact energy value when the honeycomb core loses stability under the impact load and reaches the expected size value.

[0051] 3) Implement the impact test: fix the honeycomb core prefabricated part 1 on the workbench 8 of the free-fall hammer impact testing machine, and ensure that the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com