Sample preparation method of high-purity aluminum bus metallographic sample

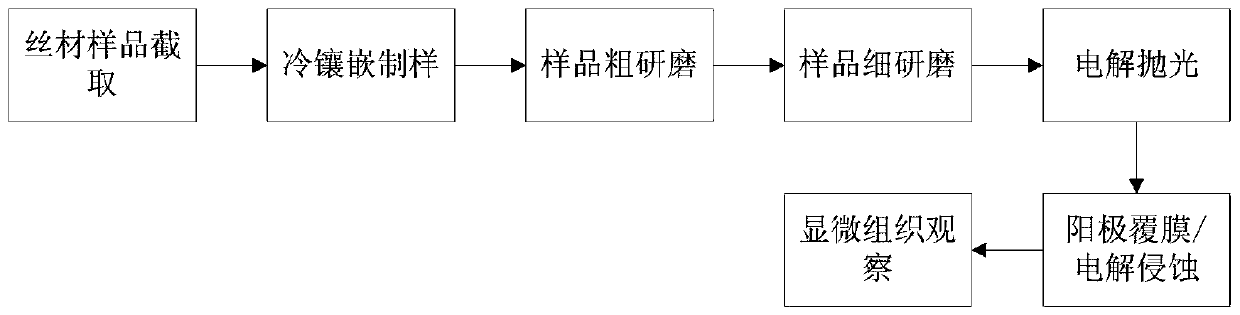

A busbar gold and sample technology is applied in the field of sample preparation of high-purity aluminum busbar metallographic samples, and achieves the effect of simple sample preparation method, solving the difficulty of grain boundary corrosion, and avoiding structure change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The specific operation steps are as follows:

[0076] (1) Sample preparation: the bus bar has a high-purity aluminum base with a purity of 99.998 or more, with 40-60ppm Ni added, and Fe, Si, and Cu elements less than 10ppm (ug / g);

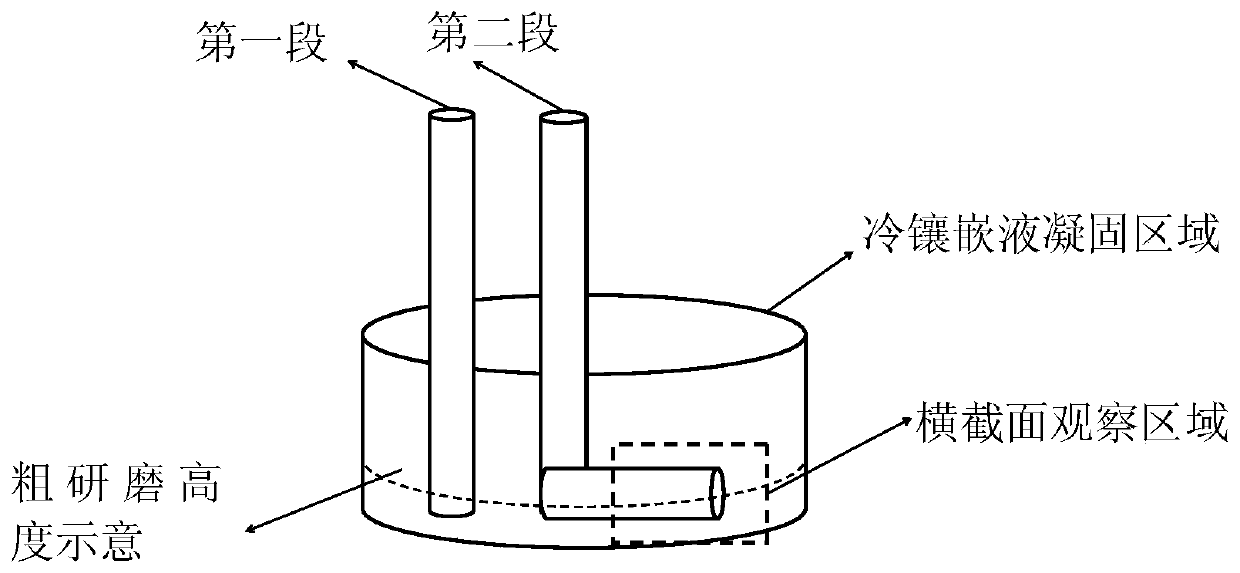

[0077] Cut two sections of busbar, the diameter of which is 5mm. The length of the first section is 50mm, and the length of the second section is 70mm. After bending the second section of bus bar 90° along the length of 20mm, place it upright with the first section in the cold mounting mold (such as figure 2 shown). Cast the cold mounting solution into the mold and take it out after the solution is solidified for grinding sample preparation.

[0078] (2) Coarse grinding: place 400# silicon carbide water sandpaper on the polishing machine, and set the speed at 300 rpm. Roughly grind the cold-mounted sample with water on a polishing machine until the height is close to the diameter of the generatrix of the bending section, that is, the bo...

Embodiment 2

[0086] The specific operation steps are as follows:

[0087] (1) Metallographic sample preparation of high-purity aluminum busbar: high-purity aluminum-based busbar with a purity of more than 99.998, added with 40-60ppmNi elements, and containing less than 10ppm (ug / g) of Fe, Si, and Cu elements;

[0088] Cut two sections of busbar, the diameter of which is 6mm. The length of the first section is 60mm, and the length of the second section is 80mm. After bending the second section of busbar 90° along the length of 20mm, place it vertically in the cold mounting mold at the same time as the first section (such as figure 2 shown). Cast the cold mounting solution into the mold and take it out after the solution is solidified for grinding sample preparation.

[0089] (2) Coarse grinding: place 400# silicon carbide water sandpaper on the polishing machine, and set the speed at 350 rpm. Roughly grind the cold-mounted sample with water on a polishing machine until the height is clos...

Embodiment 3

[0097] The specific operation steps are as follows:

[0098] (1) Sample preparation: the bus bar has a high-purity aluminum base with a purity of 99.998 or more, with 40-60ppm Ni added, and Fe, Si, and Cu elements less than 10ppm (ug / g);

[0099] Cut two sections of busbar, the diameter of which is 3mm. The length of the first section is 55mm, and the length of the second section is 75mm. After bending the second section of busbar 90° along the length of 20mm, place it vertically in the cold mounting mold at the same time as the first section (such as figure 2 shown). Cast the cold mounting solution into the mold and take it out after the solution is solidified for grinding sample preparation.

[0100] (2) Coarse grinding: place 400# silicon carbide water sandpaper on the polishing machine, and set the speed at 250 rpm. Roughly grind the cold-mounted sample with water on a polishing machine until the height is close to the diameter of the generatrix of the bending section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com