3D structured light generating component

A structured light, 3D technology, applied in the direction of optical components, optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0103] This embodiment is an embodiment of a 3D structured light generating element.

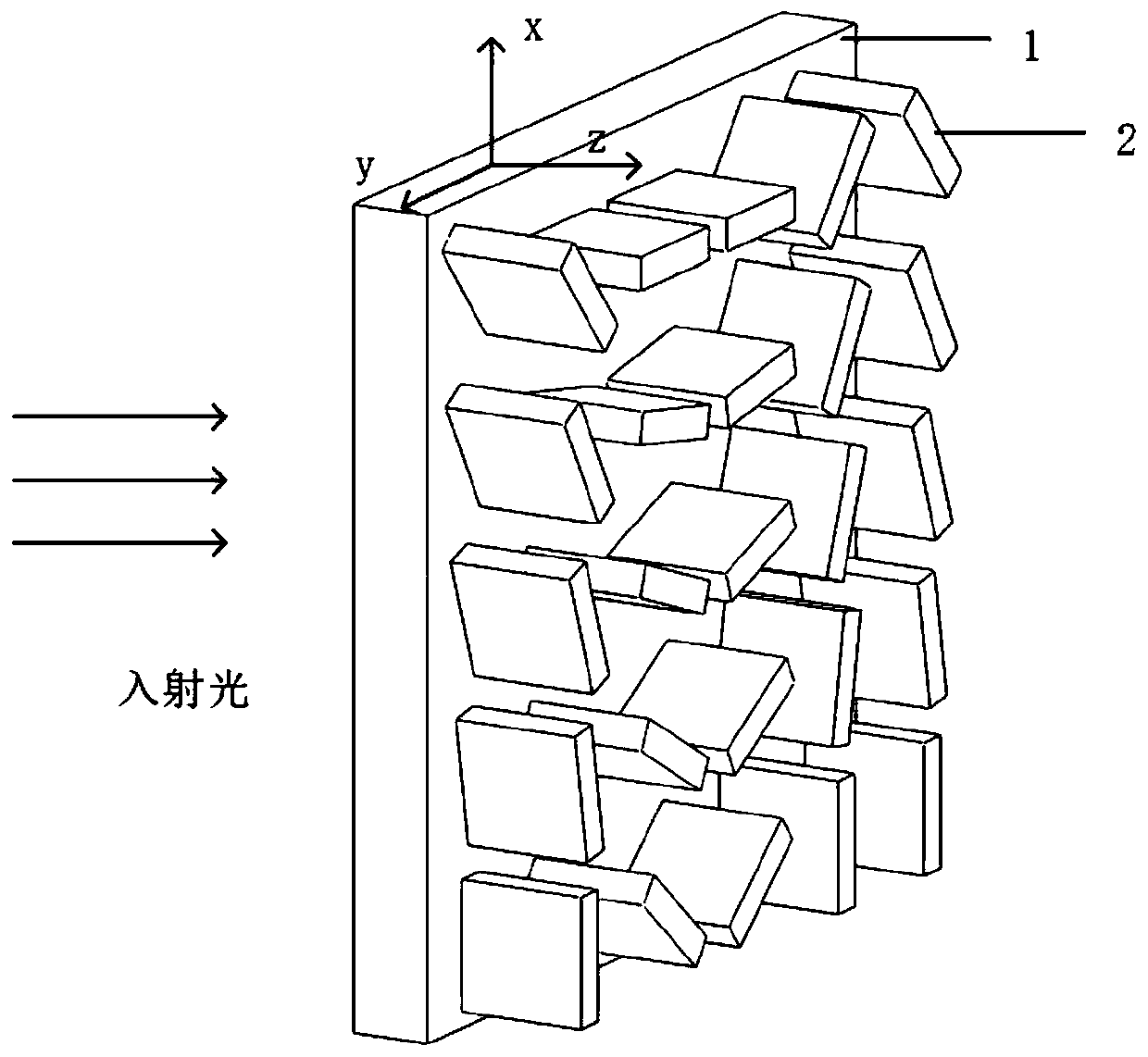

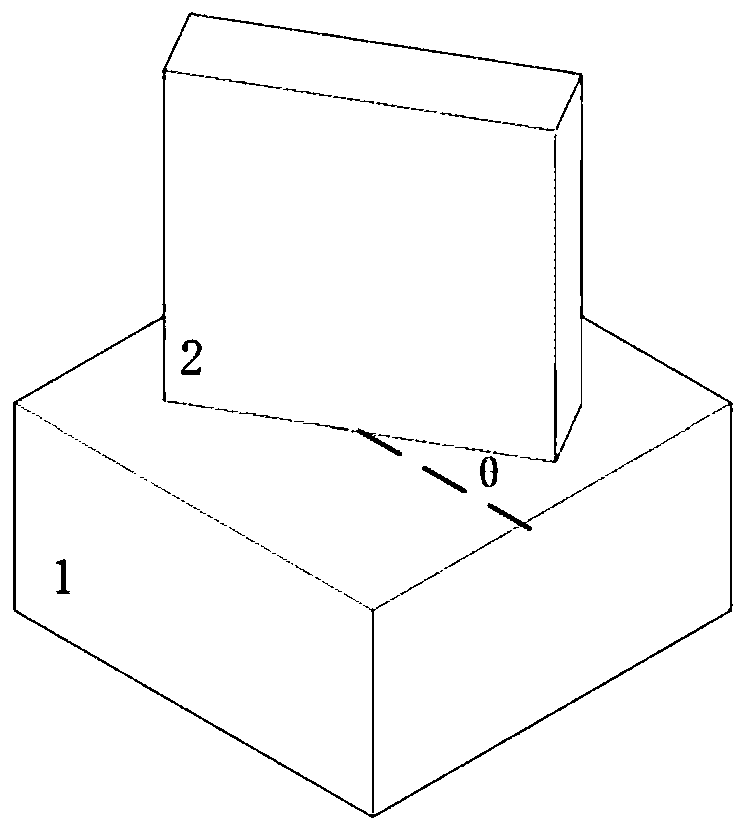

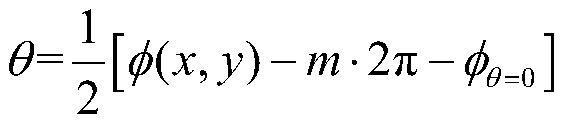

[0104] A 3D structured light generating element in this embodiment is processed by a single projection exposure, atomic layer deposition and etching process, and the structural diagram is as follows figure 1 shown. The 3D structured light generating element includes a substrate structure and multiple substructures supported by the substrate structure. The substructures are arranged in a matrix on the surface of the substrate. In the row direction and column direction of the matrix, two adjacent substructures are in the The distance of the coordinates on the substrate is a fixed value, the size of the substructures is the same, and the rotation angles are different, the substructure is at the rotation angle θ around the normal line of the substrate coordinates (x, y) and the substructure is at the substrate coordinates (x, y) The corresponding phase φ(x,y) satisfies the following relationshi...

specific Embodiment 2

[0108] This embodiment is an embodiment of a 3D structured light generating element.

[0109] A 3D structured light generating element in this embodiment is further defined as follows on the basis of the specific embodiment 1:

[0110] Complex amplitude distribution g of incident light at substrate coordinates (x, y) 0 (x,y) is:

[0111]

[0112] Among them, A 0 (x, y) is the amplitude of the incident light at the substrate coordinates (x, y), φ 0 (x, y) is the phase of the incident light at the substrate coordinates (x, y), and i is the imaginary unit;

[0113] The complex amplitude transmittance t(x,y) of the substructure is:

[0114] t(x,y)=e iφ(x,y)

[0115] Among them, φ(x, y) is the phase distribution to be obtained;

[0116] The complex amplitude distribution g(x,y) of the incident light after passing through the substructure is:

[0117]

[0118] The complex amplitude distribution u(x 1 ,y 1 , z) is:

[0119]

[0120]

[0121] Among them, (x 1 ,y ...

specific Embodiment 3

[0146] This embodiment is an embodiment of a 3D structured light generating element.

[0147] A 3D structured light generating element of this embodiment is further defined on the basis of specific embodiment 1 or specific embodiment 2 if:

[0148] The incident light is visible light, the material of the substructure is titanium dioxide or gallium nitride, and the material of the substrate is silicon dioxide;

[0149] The incident light is infrared light, and the constituent materials of the substructure and the substrate are both silicon.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap